3-6

Section 3

Fuel System

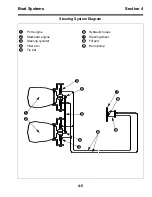

Bonding System

A green #8 awg insulated copper wire forms a com-

mon bond between the fuel tank, the fuel fill plate, and

the bonding plate on the transom.

Maintenance

Check the bonding system periodically to assure that

the wire and connections are not broken or deterio-

rated. You can verify the integrity of the system by

checking for continuity with an ohmmeter or continuity

light between the grounding plate and the fuel fill plate.

If the meter or light indicates a break in continuity,

replace the bonding system wires. After testing, coat

all screws and terminals with liquid neoprene.

Repair

The following general procedure covers the removal

and installation of the bonding system wires. Wires

are accessed through the deck access plates, under

the gunwale at the fuel fill plate, and at the transom.

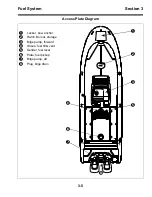

All bonding wires are accessible through the deck

access plates. Refer to the

Access Plate Diagram

in

this section for component locations.

Perform a continuity test as described in

Bonding

System Maintenance

. Remove the screw at each

terminal location of the faulty wire. Attach a new wire

to the end of the faulty wire and use the faulty wire to

pull the new wire into position. Secure the wire to the

terminal with a screw. Coat the terminal and screw

with liquid neoprene.

Summary of Contents for Boston Whaler 26 Justice Series

Page 14: ...1 10 Operator Notes...

Page 76: ...4 18 Operator Notes...

Page 94: ...5 18 Operator Notes...

Page 111: ......