140

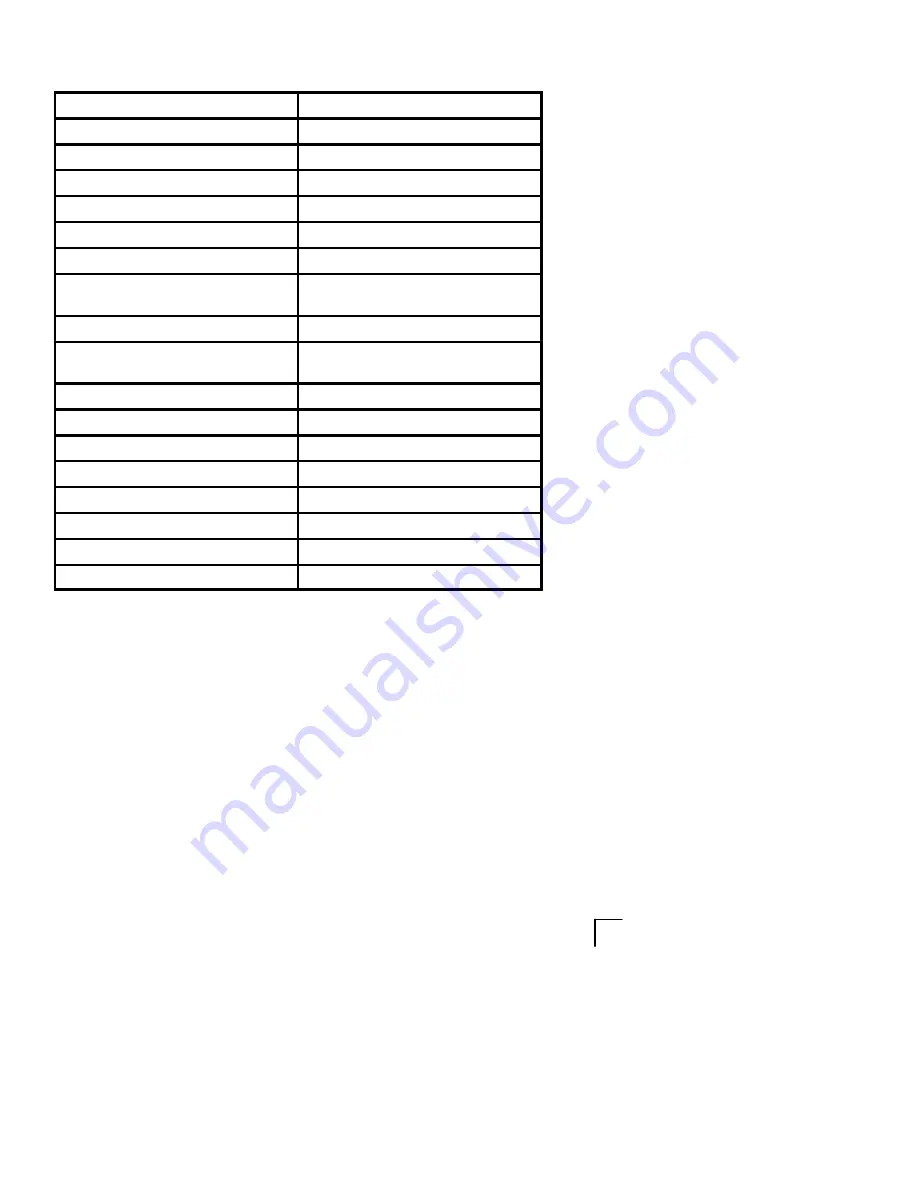

Engine Parts

5.7LX Bravo

7.4L Bravo

1.

14957

14957

2.

33-59571

33-59571

3.

805759A2

805759A2

4.

392-805570A2

392-805570A2

5.

84-816761A17

84-816608A61

6.

807252--2

807252--2

7.

27-33179--2,

27-53045--1

27-33179--2

27-53045--1

8.

57-48120A1

57-48122

9.

57-816295T

57-816295T

(7” Pulley)

10.

57-74271T

57-13457T

11.

35-807172

35-807172

12.

92-816096A12

92-816096A12

13

92-86145A12

92-86145A12

14.

92-17955A12

92-17955A12

15.

92-817529A12

92-817529A12

16.

92-17885A12

92-17885A12

17.

92-815869A12

92-815869A12

Summary of Contents for bravo one

Page 26: ...24 CA26 70514 70515 70516 70523 70517 70522 70518 70521 70520 70519 1 2 3 4 5 6 7 8 9 10 ...

Page 28: ...26 CB218 70516 1A 1B 1C 71987 70518 ...

Page 30: ...28 CA29 71466 70525 70528 70527 70526 1 2 5 4 3 71341 ...

Page 32: ...30 CB181 1 4 5 2 3 6 7 ...

Page 34: ...32 CB183 1 4 2 6 3 2 4 3 1 6 5 5 ...

Page 36: ...34 CB185 3 4 70537 71339 1 2 ...

Page 38: ...36 CA34 71338 1 3 TO 5 ...

Page 40: ...38 CB187 1 3 2 6 4 5 73976 73977 ...

Page 42: ...40 CB190 4 2A 1 1 2B 3 73978 73979 ...

Page 44: ...42 CB192 70540 70540 70540 1 2 3 ...

Page 62: ...60 CB32 71341 1 2 3 4 4 5 6 71448 70543 70544 70548 70547 70546 70545 ...

Page 64: ...62 CB207 2 A B 70979 70551 1 2 71987 71773 ...

Page 66: ...64 CA62 71345 1 2 3 2 70571 70572 71344 70544 ...

Page 68: ...66 CB354 1B 1A 2 70570 70569 70568 1C 72522 3 71987 ...

Page 70: ...68 CB177 4 5 70556 71359 1 3 71903 71904 71901 2 ...

Page 72: ...70 CB429 6 8B 10 70558 71346 71347 70559 9 71569 8A ...

Page 74: ...72 CB155 2 70561 7 5 72239 ...

Page 76: ...74 CB158 1 2 3 4 5 70561 ...

Page 78: ...76 CB150 6 7 9 10 12 72239 11 8 ...

Page 80: ...78 CB63 1 2 3 70565 71353 70564 4 71170 ...

Page 82: ...80 CB442 70566 1B 2 70567 1C 74789 3 1A 71355 71334 4 71334 ...

Page 84: ...82 CB74 5 1 3 2 7 4 70351 70562 71349 70563 6 70353 70351 ...

Page 86: ...84 CB78 71345 50681 70573 1 2A 71169 2B ...

Page 88: ...86 CB226 70578 70577 70575 2 3 4 71176 1 73919 ...

Page 90: ...88 CB333 71966 72032 1 2 71804 72029 3B 3A 3B ...

Page 92: ...90 CB95 1 2 71176 3 ...

Page 94: ...92 CA97 1 71925 71918 SEE CAUTION ...

Page 96: ...94 CA101 2 71926 71921 71923 71919 4 3 ...

Page 102: ...100 CB431 2 2 74158 71332 3 5 71448 ...

Page 104: ...102 CB433 8 71217 71758 9B 7B 74152 74811 6 9A 74493 7C 74793 7A 71334 ...

Page 106: ...104 CB111 2 70583 ...

Page 108: ...106 CB113 71170 70584 4A 6 71334 70586 5A 4B 5B 7 71217 ...

Page 110: ...108 CB437 71515 74073 2 4 ...

Page 112: ...110 CB439 71170 6 7 5 71217 74793 ...