Bandit

10

Copyright 6/12

MODEL 200 UC

The machine was built with a chipper hood

engine disable plug which disables the engine if it

is not installed properly with the hood pin holding

the chipper hood in the closed position. Correctly

installed and maintained, the engine will not start or

it will shut off if the chipper hood engine disable plug

is disconnected. The chipper hood must NEVER be

opened, or pushed closed if the chipper disc/drum

is turning.

DO NOT slam the chipper hood to the open

position. This will cause damage to the hinge. If

your hinge has become damaged by slamming

the hood to the open position, Replace The Hinge

Immediately! If the hinge has become damaged it

will cause misalignment of the hood, the chipper

disc/drum may then hit the hood and cause a serious

accident! Lubricate the hood hinge daily.

Do not work on the machine if the engine is

running with the clutch disengaged. A clutch can

self engage if either the pilot or throw‑out bearing

happens to seize to the main output shaft.

There are various types of clutches (PTO’s)

available for this type of equipment. Make sure

to study the original clutch manufacturer’s manual

that is provided with the machine and follow its

instructions for operation, service, and adjustments.

Some styles require clutch engagement to be

maintained so that it takes a lot of force, others will

require very little force, and some are push button,

electric, manual lever, or hydraulic activation. Each

different style clutch (PTO) is a very expensive item

that will fail if not correctly maintained and adjusted.

It will be quite costly if a few minutes are not taken

daily, weekly, and monthly to keep the clutch serviced

as required.

The operator must take care in the engagement

and disengagement of the clutch, engine RPM

should always be below 1000 RPM. When the

engine has sufficiently warmed up, bump the clutch

handle against engagement to start the chipper

disc/drum turning. This will have to be repeated

until the chipper disc/ drum is turning at proper

ratio with engine RPM. Then push the handle all

the way in gear until it locks into position securely.

After engagement raise engine RPM to full throttle.

Engaging and disengaging the clutch at high

engine RPM will quickly and excessively wear out

clutch plates as well as bearings. Refer to clutch

manufacturer’s manual for proper service and

operation.

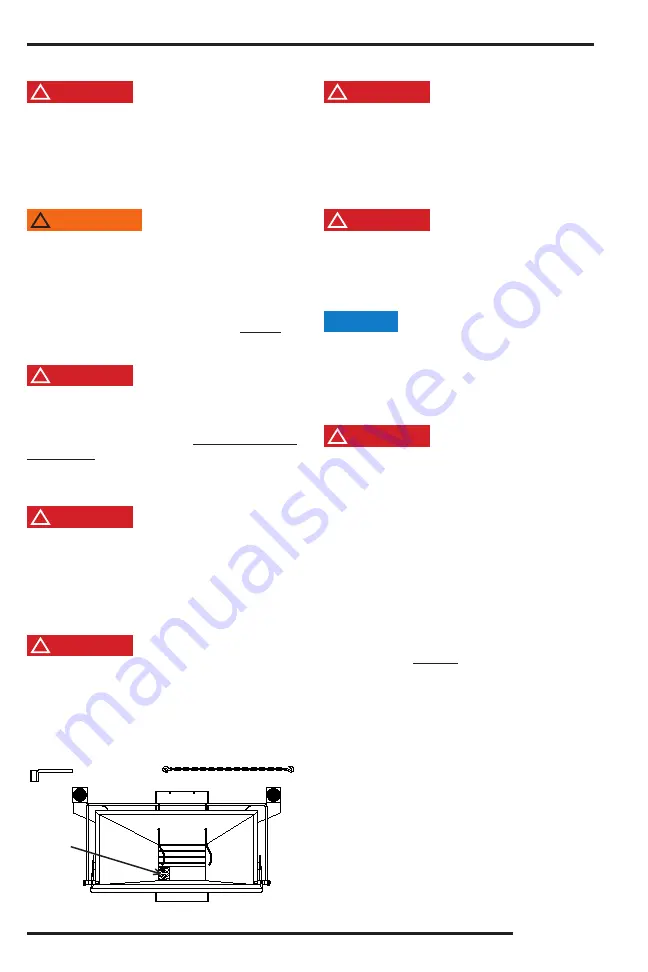

Do not work inside the mouth of the chipper or

around the feedwheel(s), until you have installed the

yoke lock pin completely and securely to help keep

the top feedwheel in the raised position. Remove

top wheel springs if equipped, block and chain top

wheel up before doing any work inside throat.

Never turn the chipper disc/drum by hand, always

carefully use a pry bar or wood bar. This will help

prevent the person turning the disc/drum from being

injured should the disc/drum break loose.

A sight hole in the chipper beltshield has been

provided. If chipper belts are moving do not open

chipper hood. Do not stick fingers in sight hole.

DANGER

!

SAFETY PROCEDURES

SAFETY PROCEDURES

DANGER

!

DANGER

!

DANGER

!

WARNING

!

Use Chain

Use

Wooden

Block

Use Yoke

Lock Pin

If the chipper is properly maintained and operated

correctly, the chipper should not plug. In the unlikely

event that the chipper becomes plugged, do not

attempt to clean out the discharge or chipper housing

in the field. Take the machine to a local dealer or

professional shop. If the machine is a rental, take it

back to the rental company.

If the discharge or hood need to be removed,

always use some sort of mechanical device like an

overhead hoist, loader, lift truck, etc. that is rated for

lifting that component. Follow all OSHA instructions

for lifting.

Before opening or closing the feedwheel trap

door: disengage clutch, turn off engine, wait for the

disc/drum to come to a complete stop, install the

disc/drum lock pin, disconnect battery, and make

sure the ignition key is in your possession. In the

event that dirty material is being run through the

chipper the feedwheel trap door can be opened.

DANGER

!

DANGER

!

DANGER

!

Do not attempt to start the engine or engage the

engine PTO (power‑take‑off) system on this machine

if the chipper disc/drum is jammed or frozen in place.

If you do, you will damage or ruin the drive belts

and/or the PTO which will not be covered under

warranty and will cost you down time and money.

NOTICE

Summary of Contents for 200 UC

Page 17: ......

Page 35: ...Bandit 19 Copyright 6 12 MODEL 200 UC DECALS ...

Page 36: ...Bandit 20 Copyright 6 12 MODEL 200 UC DECALS ...

Page 69: ...Bandit 53 Copyright 6 12 MODEL 200 UC HYDRAULIC SECTION HYDRAULIC SECTION ...

Page 126: ...Bandit 110 Copyright 6 12 MODEL 200 UC SERVICE RECORD SERVICE RECORD DATE DESCRIPTION AMOUNT ...