Bandit

73

Copyright 6/12

MODEL 200 UC

Chipper knives MUST be kept sharp at all times

for the ultimate chipper and knife performance.

The main cause of poor cutting performance is dull

knives.

Dull Knives Cause:

‑ Excessive waste of engine horsepower

‑ Bad quality chips; chunks, slivers, etc.

‑ Excessive strain on knives and mounting hardware

‑ Excessive strain on chipper disc/drum bearings

and total machine

‑ Excessive chipping vibration damaging the

machine

‑ Excessive strain on drives, PTO’s, engines, etc.

‑ Increase the probability of the discharge plugging

and decreases the throwing distance

‑ Loss of time and money

The Dulling Of Chipper Knives Is Caused By:

‑ Poor quality knives

‑ Improper anvil to knife clearance

‑ Force feeding wood faster than chipper will accept

‑ Dirt, grit, or foreign material on the wood

‑ Chipper knives ground at wrong angle

‑ Improper care of knives and knife hardware

These are just a few factors, there are other

situations that can lead to the dulling of chipper knives.

Many times a chipper knives cutting edge/point

can be brought back to a good edge with a #10 Flat

Bastard Mill File. This can reduce the amount of

regrinding.

Typical Knife Grinding Angles:

“Bolt‑In” Knives = 30° to 31° Angle

Knives should be replaced in sets. These sets

are determined by the amount of resharpening

done to the knives (knife width). Regrinding knives

reduces the width of the knife. Knife replacement

should be done in sets of the same width knives.

That will reduce chipping vibration and increase

chipping performance.

Do not grind the knives in a direction which

produces a radius, or hollow grind, on the surface

of the knife. Strength and life of the cutting edge is

reduced.

‑ For maximum chipper efficiency, the original

cutting angle must be maintained when the

knives are sharpened. The knives should be

machine ground to produce a flat, straight edge.

‑ Do not sharpen the knives with a hand held

power grinder. The knife angle can’t be held and

heat will distort the metal.

‑ Sharpening techniques should be the same as

those employed for any high carbon steel

cutting edge. Use a coolant and exercise care

not to draw temper or crack the cutting edges

by excessive heating.

‑ Knives may be sharpened repeatedly as long as

their original width is not reduced to less than the

specified minimum width. If a knife measures less

than the specified minimum width after sharpening,

it must be discarded.

‑ Inspect the knives after grinding to ensure the

knives are free of cracks.

‑ Maintain spare sharpened knives to avoid

downtime for knife sharpening.

‑ Keep knives sharp.

‑ Keep knife angle correct when grinding.

‑ Do not over grind so knife is narrower than

allowed width, or you will pack wood and break

knives.

‑ Use correct knife size, knife quality, knife

mounting hardware, and torque knife mounting

hardware to the specified torque.

‑ Replace knife mounting hardware after (5) times

of tightening.

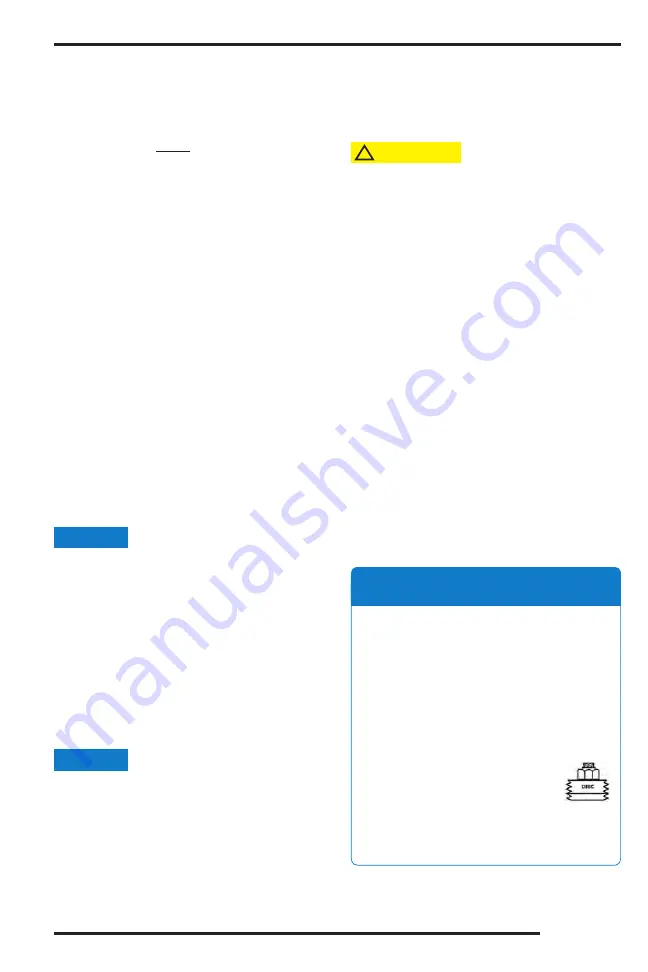

NOTICE

USE CORRECT KNIFE AND HARDWARE

DO NOT

use a size or style chipper knife, bolt or nut

other than factory approved for this chipper ‑ see

manual.

DO NOT

over torque or under torque knife bolts and

nuts ‑ see manual.

DO NOT

resharpen knife more

than minimum width ‑ see manual.

DO NOT

use a knife bolt or nut which has been tightened

over (5) times ‑ replace.

DO NOT

improperly install the knife nuts.

Flat surface of nut goes toward the chipper

disc.

DO

check the chipper disc/drum daily for secure welds,

cracks, excessive wear, torqued bolts, elongated bolt

holes and/or good bolt hole threads. If problem is found,

contact chipper manufacturer or authorized dealer.

CHIPPER SECTION

KNIFE GRINDING AND FILING

Only Bandit knives and hardware are recommended for use in your Bandit chippers. Only then can you

be assured of a quality product that fits and performs the best to the standards of excellence that is expected

from the Bandit chipper.

NOTICE

NOTICE

CAUTION

!

Summary of Contents for 200 UC

Page 17: ......

Page 35: ...Bandit 19 Copyright 6 12 MODEL 200 UC DECALS ...

Page 36: ...Bandit 20 Copyright 6 12 MODEL 200 UC DECALS ...

Page 69: ...Bandit 53 Copyright 6 12 MODEL 200 UC HYDRAULIC SECTION HYDRAULIC SECTION ...

Page 126: ...Bandit 110 Copyright 6 12 MODEL 200 UC SERVICE RECORD SERVICE RECORD DATE DESCRIPTION AMOUNT ...