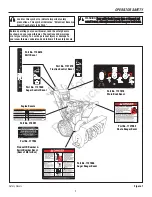

OPERATION

14

TRACTION LOCK PINS

The right traction wheel can be completely released using the locking pin

(A

A, Figure 6). This allows the unit to be easily moved with the engine off.

Traction Lock Pins

Figure 6

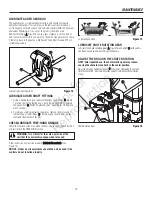

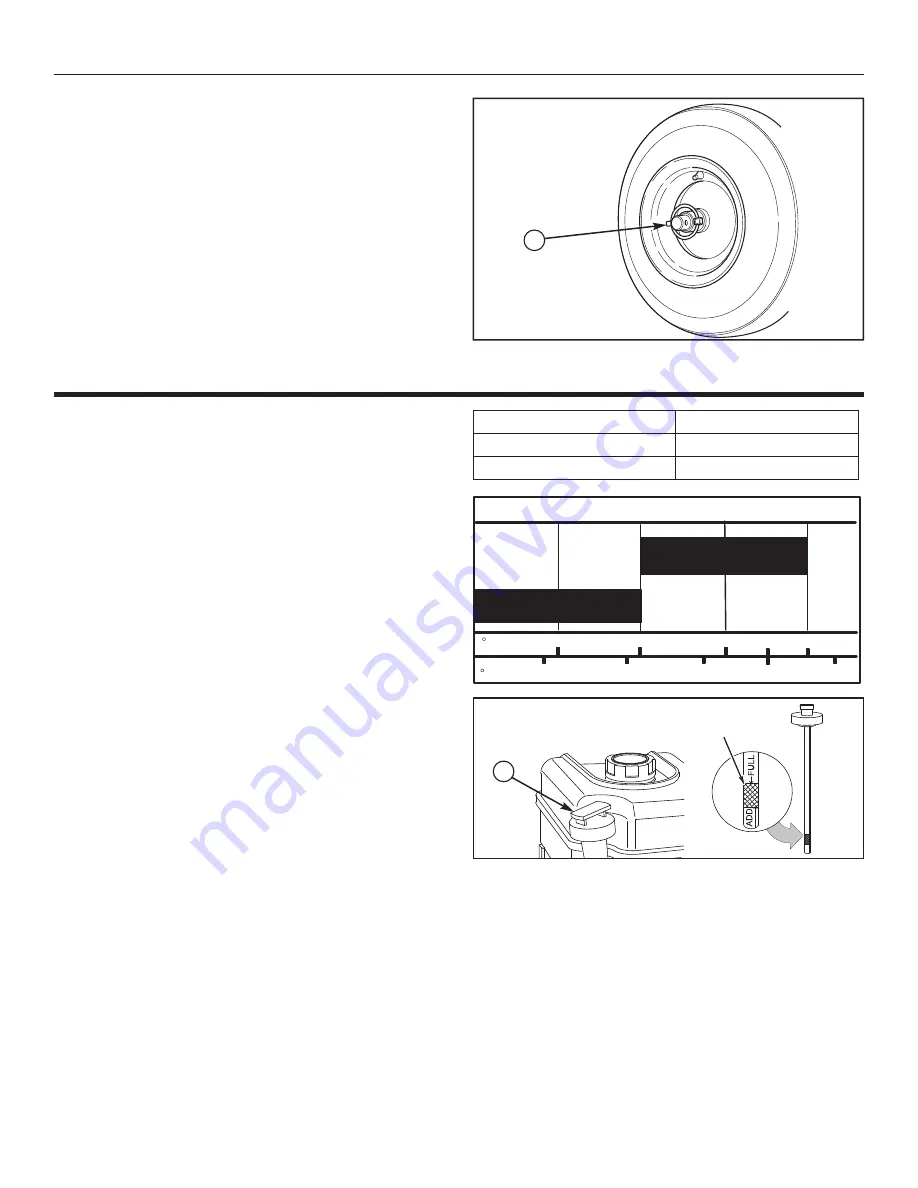

CHECK THE OIL (BEFORE STARTING ENGINE)

NOTE: The engine was shipped from the factory filled with oil.

Check the level of the oil. Add oil as needed.

1. Make sure the unit is level. Use a high quality detergent oil classified

“For Service SG, SH, SJ, SL, or higher”.

2. Remove the oil fill cap/dipstick (A

A, Figure 7) and wipe with a clean cloth.

3. Insert the oil fill cap/dipstick and turn clockwise to tighten.

4. Remove the oil fill cap/dipstick and check the oil.

NOTE: Do not check the level of the oil while the engine runs.

5. If necessary, add oil until the oil reaches the FULL mark on the oil fill

cap/dipstick. Do not add too much oil.

6. Tighten the oil fill cap/dipstick securely each time you check the oil

level.

NOTE: For extreme cold operating conditions of 0°F (-18°C) and

below, use a synthetic 5W30 motor oil for easier starting.

NOTE: S.A.E. 5W30 motor oil may be used to make starting

easier in areas where the temperature is 20°F (-7°C) to 0°F

(-18°C). Synthetic 5W30 is acceptable for all temperatures.

DO NOT mix oil with gasoline. See Chart for oil

recommendations.

F

−20

0 20 32 40

C

−30

−20

−10 0 10

5W30

Synthetic 5W30

SAE VISCOSITY GRADES

TEMPERATURE

TYPE OF OIL

0°F (-18°C) and above

S.A.E. 5W30

0°F (-18°C) and below

Synthetic 5W30

FULL

Checking the Oil

Figure 7

A

A

Not

for

Reproduction