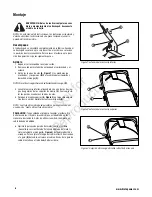

Blade Service

WARNING: Before you inspect the blade or the

blade adapter, disconnect the wire to the

spark plug. If the blade hits an object, stop the

engine. Disconnect the wire to the spark plug.

Check the unit for damage.

Frequently check the blade for wear or damage such as

cracks. Frequently check the bolt that holds the blade. Keep

the bolt tight. If the blade hits an object, stop the engine.

Disconnect the wire to the spark plug. Check the blade

adapter

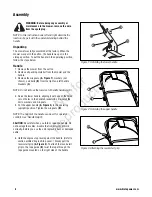

(A, Figure 18)

for damage. Check for a bent or

damaged blade, a badly worn blade, or other damage. Before

you operate the unit, damaged parts must be replaced with

factory replacement parts or equivalent. For safety, replace

the blade every two years. Keep a sharp edge on the blade. A

blade that is not sharp will cause the ends of the grass to

become brown. Remove the blade as follows.

Removing the Blade

WARNING: Before you remove the blade,

disconnect the wire to the spark plug. The

blade has sharp edges. When you hold the

blade, use gloves or cloth material to protect

your hands.

1. Drain the fuel tank.

2. Lift the side of the mower that has the muffler or spark

plug.

3. Use a piece of wood to keep the blade from rotating.

4. Remove the bolt

(B, Figure 18)

that holds the blade

with a 9/16” (14mm) wrench.

5. Check the blade

(C)

according to the “Blade Service”

instructions. Replace a badly worn or damaged blade

with a factory replacement blade or equivalent.

6. Mount the blade with the curved edges toward the

housing. If the blade is upside down, the blade will not

cut correctly and can cause an accident.

7. Fasten the blade with the original washer

(D)

and bolt.

Make sure the outside rim of the Belleville washer is

toward the blade.

8. Tighten the bolt that holds the blade to a torque of 30

foot pounds.

WARNING: Always keep the bolt that holds the

blade tight. A loose bolt or blade can cause an

accident.

Sharpening the Blade

WARNING: Vibration is the result if the blade

is not correctly balanced. A blade that is

damaged with cracks can break and cause

an accident.

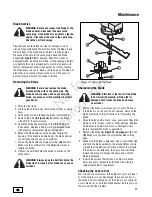

1. Sharpen the blade two times a year or every 25 hours.

2. If the blade is on the unit, do not sharpen. Remove the

blade according to the instructions in “Removing The

Blade”.

3. Clean the blade with a brush, soap, and water. Check the

blade. Look for cracks, nicks, or other damage. Replace

a blade that is badly worn, bent, or damaged with a

factory replacement blade or equivalent.

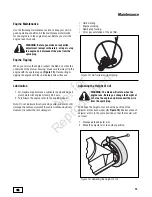

4. Sharpen the blade

(A, Figure 19, next page)

with a file

(B)

. Make sure you keep the original beveled cutting

edge.

5. Make sure the blade is balanced. Use a screwdriver

(C)

and hold the blade parallel to the ground

(D)

as shown.

A blade that is balanced will stay parallel to the ground.

If the blade is not balanced, the heavy end will rotate

toward the ground. Sharpen the heavy end until the

blade is balanced.

6. A new blade will cut better than a badly worn blade.

Every two years replace the old blade with a factory

replacement blade or equivalent.

Checking the Level of Cut

Test the unit in a small area. If the height of cut is not level

or if the cut grass is not discharged, the cause can be: (1)

the blade is bent or damaged, (2) the blade is not sharp, (3)

a worn blade, (4) or a broken blade adapter. Before you use

the unit, correct the problem.

Figure 18: Removing the blade

D

B

D

C

B

C

A

A

Maintenance

17

en

Not

for

Reproduction