51

5.

Heat pump

(See Fig. 25 -- 32 for thermostat connections.) When

installed with a heat pump, the furnace control

automatically changes the timing sequence to avoid long

blower off times during demand defrost cycles. When the

R--to-- W--and--Y1 or R--to--W--and--Y1--and--G circuits

are energized the furnace control CPU will switch to or

turn on the blower motor BLWM at HEAT speed, and

begin a heating cycle. The blower motor BLWM will

remain on until the end of the prepurge period, then shut

off for 24 seconds then come back on at HEAT speed.

When the W input signal disappears, the furnace control

begins a normal inducer post--purge period and the blower

remains running at HEAT speed for the selected

blower--OFF delay period then switches to low--cool

speed

(same

speed

as

FAN).

If

the

R--to--W--and--Y1--and--G signals disappear at the same

time, the blower motor BLWM will remain on for the

selected blower--OFF delay period. If the R--to--

W--and--Y1 signals disappear, leaving the G signal, the

blower motor BLWM will remain on for the selected

blower--OFF

delay

period

then

switch

to

continuous--blower speed. When the R--to--W--and--Y/Y2,

R--to--W--and--Y/Y2--and--G,

R--to--W--and--Y1--and--

Y/Y2, or R--to--W-- and--Y1--and--Y/Y2--and--G circuits

are energized the furnace control CPU will switch to or

turn on the blower motor BLWM at HEAT speed, and

begin a heating cycle. The blower motor BLWM will

remain on until the end of the prepurge period, then shut

off for 24 seconds then come back on at HEAT speed.

When theWinput signal disappears, the furnace control

begins a normal inducer post--purge period and the blower

switches to COOL speed after a 3 second delay. If the

R--to--W--and--Y/Y2--and--G or R--to--W--and--Y1--and --

Y/Y2--and--G signals disappear at the same time, the

blower motor BLWM will remain on for the selected

blower--OFF delay period. If the R--to--W--and--Y/Y2 or

R--to--W--and--Y1--and--Y/Y2 signals disappear, leaving

the G signal, the blower motor BLWM will remain on for

the selected blower--OFF delay period then switch to

continuous blower speed.

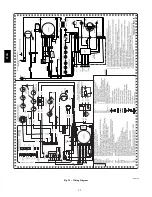

Wiring Diagrams

Refer to Fig. 59 for wiring diagram.

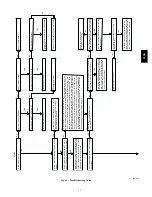

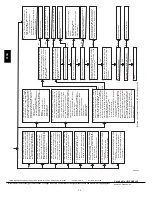

Troubleshooting

Refer to the service label. (See Fig. 55.) The Troubleshooting

Guide (See Fig. 60) can be a useful tool in isolating furnace

operation problems. Beginning with the word “Start,” answer

each question and follow the appropriate arrow to the next item.

The Guide will help to identify the problem or failed component.

After replacing any component, verify correct operation

sequence.

313A

Summary of Contents for 313AAV

Page 41: ...41 Table 13 Orifice Size and Manifold Pressure In wc for Gas Input Rate A08220 313A...

Page 42: ...42 Table 13 Orifice Size and Manifold Pressure In wc for Gas Input Rate CONT A08220A 313A...

Page 44: ...44 Table 14 Orifice Size And Manifold Pressure In wc For Gas Input Rate A08221 313A...