The control in this furnace is equipped with an LED status light to

aid in installation, servicing, and troubleshooting. It can be viewed

through the sight glass or window on blower access door. The

control indicates status with the LED on continuously, rapid

flashing, or a code composed of 2 digits. (The first digit is the

number of short flashes, the second is the number of longs flashes.)

Refer to service label on blower compartment door for code

explanations and useful troubleshooting suggestions. (See Fig. 12.)

It is important to note that power to furnace must not be interrupted

and furnace blower door must not be removed until the LED status

code(es) is recorded. When power to control is interrupted, status

memory is erased.

The control will store up to 5 previous codes but will not store

non-current codes longer than 48 hr. To retrieve previous codes, if

present, no thermostat inputs to control must be present and all

time delays must expire. Remove 1 of the red main limit wires 1

to 4 sec until the LED light goes out, then reconnect it. (See Fig.

5 and 6.) (Do not leave red wire disconnected for longer than 4 sec

as control will assume an overtemperature condition exists and

will respond with indoor blower operation.) This places control in

status recall mode and displays first code stored in memory.

Record code and repeat the disconnect and reconnect of red wire,

→

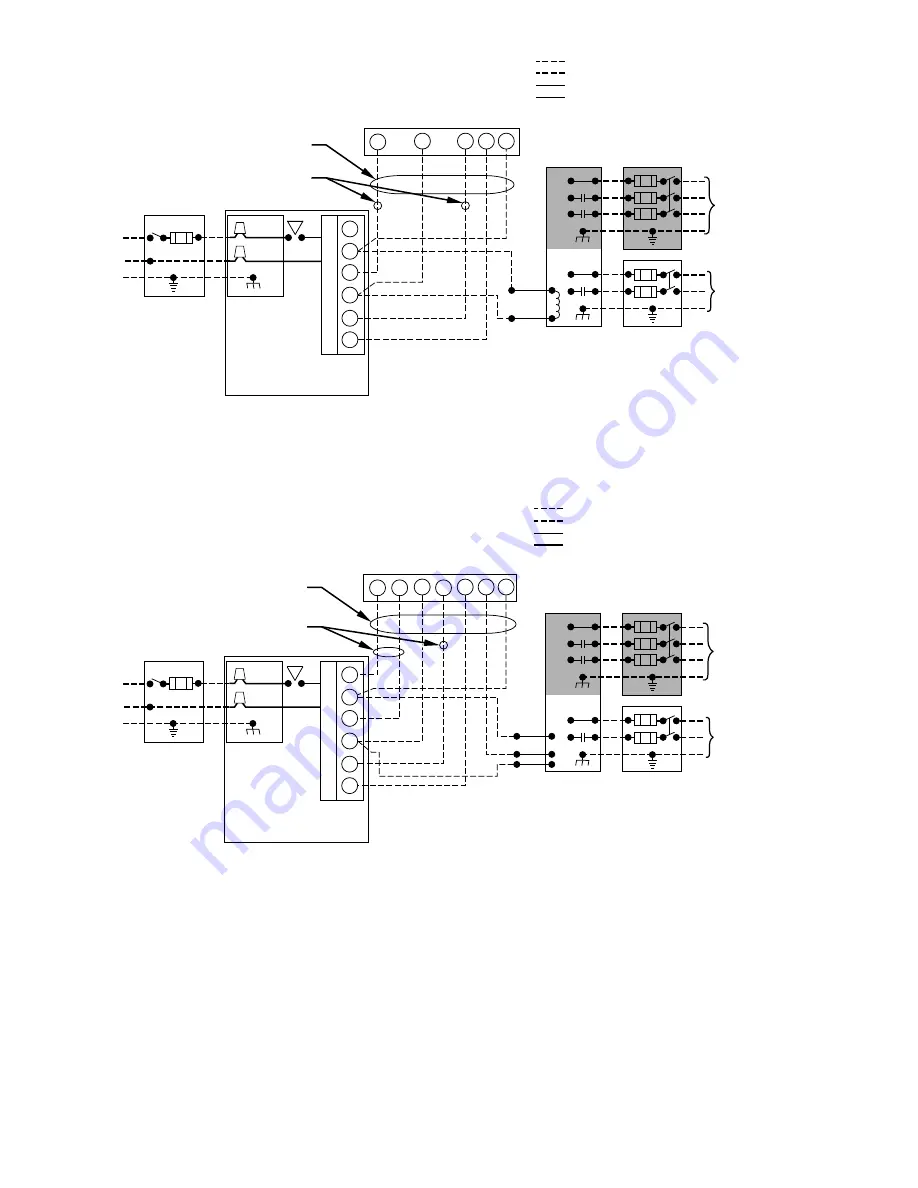

Fig. 9—Heating and Cooling Application Wiring Diagram for Single-Stage Thermostats

and Single-Speed Condensing Units

A97443

115-V FUSED

DISCONNECT

SWITCH

(WHEN REQUIRED)

JUNCTION

BOX

CONTROL

BOX

24-V

TERMINAL

BLOCK

TWO-WIRE

HEATING-

ONLY

FIVE

WIRE

1-STAGE THERMOSTAT TERMINALS

FIELD-SUPPLIED

FUSED DISCONNECT

CONDENSING

UNIT

FURNACE

COM

R

W

Y

R

G

C

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

WHT

BLK

WHT

BLK

W/W1

W2

Y/Y2

G

NOTES:

1. Connect Y-terminal as shown for proper operation.

2. Some thermostats require a "C" terminal connection as shown.

3. If any of the original wire, as supplied, must be replaced,

use same type or equivalent wire.

→

Fig. 10—Heating and Cooling Application Wiring Diagram for 2-Stage Thermostats

and/or 2-Speed Condensing Units

A97444

115-V FUSED

DISCONNECT

SWITCH

(WHEN REQUIRED)

JUNCTION

BOX

CONTROL

BOX

24-V

TERMINAL

BLOCK

THREE-WIRE

HEATING-

ONLY

SEVEN

WIRE

2-STAGE THERMOSTAT TERMINALS

FIELD-SUPPLIED

FUSED DISCONNECT

2-SPEED

CONDENSING

UNIT

FURNACE

G

R

W2

Y2

G

Y1

C

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

Y2

Y1

C

WHT

BLK

WHT

BLK

W1

R

W2

COM

W/W1

Y/Y2

NOTES:

1. Connect Y-terminal as shown for proper operation.

2. Some thermostats require a "C" terminal connection as shown.

3. If any of the original wire, as supplied, must be replaced,

use same type or equivalent wire.

—6—

Summary of Contents for 330JAV

Page 11: ...11...