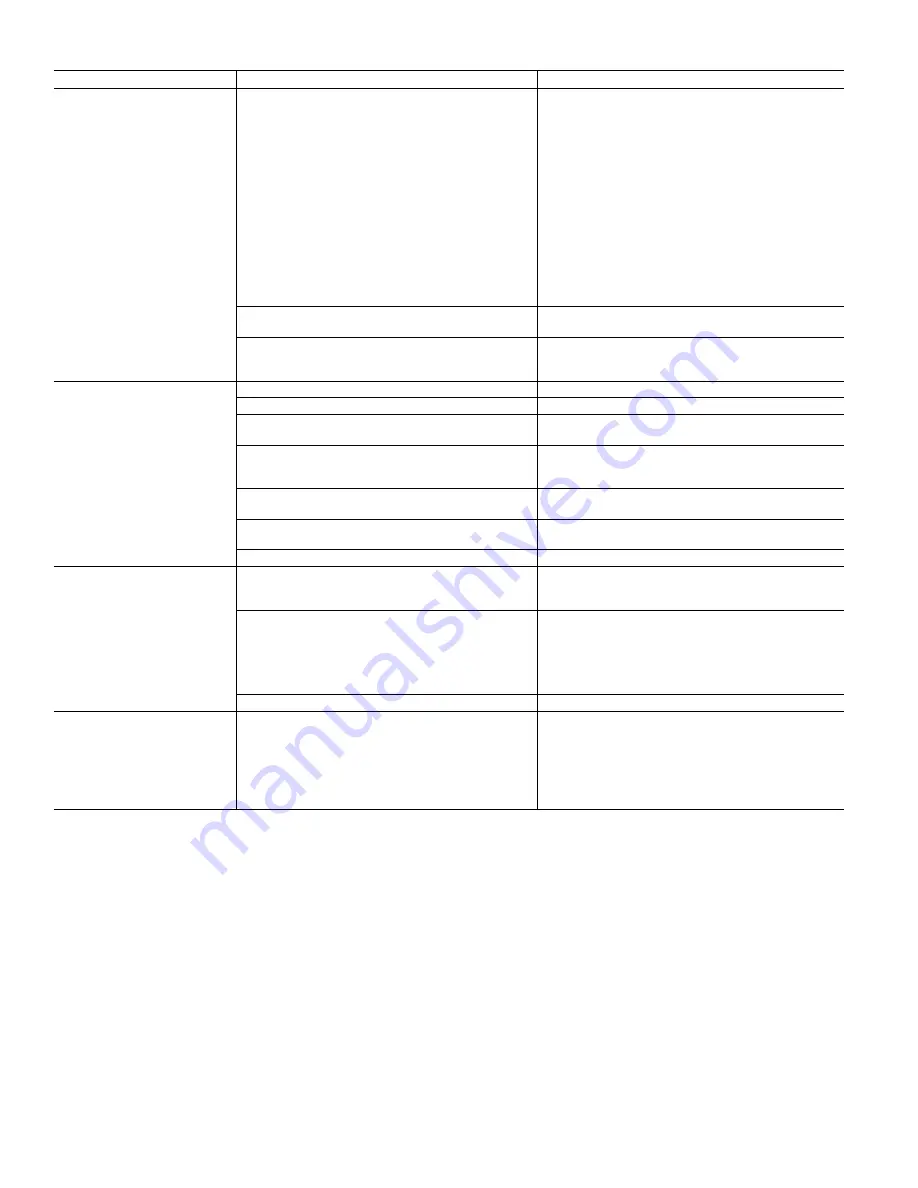

TROUBLE ANALYSIS CHART

SYMPTOM

PROBABLE CAUSE

REMEDY

Pilot will not light.

No spark at electrode.

Check 115-v electrical supply to furnace.

Check spark gap.

Check draft inducer motor, repair as necessary.

Check pressure switch; contacts must be closed

(vent piping must be free from obstructions). Also,

check for kinks or obstructions in pressure tubing.

Check for accumulation of moisture or dirt on

electrode ceramic; clean if necessary.

Check for cracked ceramic; replace electrode if

necessary.

Check for loose or broken wiring at and between

control box and electrode.

Check for 24-v electrical supply to ignition control

box. If 24v are supplied to box, and above steps

have been completed; replace ignition control

box.

Spark shorting out to main burner.

Align electrode tip away from burner—maintain

proper spark gap.

No gas at pilot assembly.

Check if pilot gas valve is opening.

Check for broken or loose wiring connections.

If no deficiency is found, replace gas valve.

Burners will not ignite.

No 115-v electrical supply to furnace.

Check fuse, circuit breaker, and wiring.

No 24-v electrical supply to control circuit.

Check transformer; replace if necessary.

Miswired or loose connections.

Check all wiring and connections; repair as nec-

essary.

No gas at main burners.

Check if main gas valve is opening.

Check for broken or loose wiring connections.

If no deficiency is found, replace gas valve.

Flame rollout shutoff switch activated.

Check venting system for blockage; correct im-

proper venting condition.

Flame probe or connecting lead shorted or open.

Correct electrical shorting or open circuit as re-

quired.

Dirty pilot (yellow flame).

Clean pilot orifice.

Inadequate heating.

Gas input to furnace too low.

Check gas pressure at manifold. Clock gas meter

for input. If too low, increase manifold pressure

and/or replace orifices with correct size.

Limit switch cycles main burners.

Dirty air filters; clean or replace.

Blower speed too low; adjust to higher speed.

Restricted supply- or return-air ductwork or regis-

ters; repair as necessary.

Incorrect heat anticipator setting; determine

proper setting and adjust as necessary.

Furnace undersized for application.

Replace with properly sized furnace.

Aldehyde odors (CO),

sooting or floating flame.

Incomplete combustion

(poor flame characteristics).

Lack of combustion air—see installation instruc-

tions.

Overfired furnace; reduce input or replace ori-

fices.

Check vent piping for restriction; clean as neces-

sary.

Cracked heat exchanger; replace.

© 1992 BDP Co. • P.O. Box 70 • Indianapolis, IN 46206

Printed in U.S.A.

—6—

15074

Catalog No. BDP-3334-916