18

Depending on above inspection, service could also include a

cleaning and vacuuming of heat exchanger tubes and possibly the

heat exchanger drum section.

Removal of any heat exchanger components which are sealed by

gaskets requires replacement of gasket.

This furnace should never be operated without an air filter.

Disposable filters should be replaced at least once a year. If

equipped to provide cooling, filters should be replaced a minimum

of twice a year. Permanent filters should be cleaned at least twice a

year.

ALWAYS KEEP MAIN OIL VALVE TURNED OFF IF

BURNER IS SHUT DOWN FOR AN EXTENDED PERIOD OF

TIME.

Step 2 — Oil Burner

For optimum performance, oil--burner nozzle should be replaced

once a year. Contact your service technician if you are unsure of

this procedure.

The procedure for nozzle installation and/or replacement is

outlined in oil burner instruction manual which came with furnace.

After replacement of nozzle, burner should be adjusted in

accordance with Combustion Check section of this instruction.

Step 3 — Heat Exchanger and Flue Pipe

Ordinarily, it is not necessary to clean heat exchanger or flue pipe

every year, but it is necessary to have your service technician check

unit before each heating season to determine whether cleaning or

replacement of parts is required.

If cleaning is necessary, the following steps should be performed:

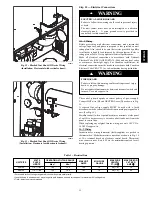

BURN HAZARD

Failure to follow this caution may result in personal injury.

If furnace has been in operation, some surfaces may be

hot. Allow time for unit to cool down.

CAUTION

!

1. Turn off all oil and electrical supplies upstream of furnace.

2. Disconnect flue pipe.

3. Remove flue collar panel located in front part of furnace.

4. Remove baffle from secondary heat exchanger.

5. Disconnect oil line and remove oil burner from furnace.

6. Open 2 cleanout doors located in upper part of front panel

of furnace.

7. Clean secondary tubes, and primary cylinder with stiff

brush and vacuum cleaner.

8. Before re--assembly, the heat exchanger and combustion

chamber should be inspected to determine if replacement is

required.

9. After cleaning, replace baffle, flue--collar plate, oil burner,

and close the 2 cleanout access doors. Reconnect flue pipe

and oil line.

10. Re--adjust burner for proper operation.

Step 4 — Blower Removal

To remove blower from furnace:

1. Turn off all oil and electrical supplies upstream of furnace.

2. Remove burner access and blower door.

3. Remove blower retaining screw (on blower shelf).

4. Remove cover from control box and disconnect thermostat

and power wires from the board.

5. Slide blower forward on rails toward front of unit.

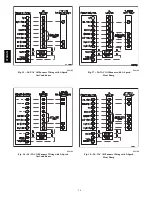

6. Reverse items 1 through 5 to re--install blower. Refer to

wiring diagram (See Fig. 14) of these instructions or dia-

gram located on inside of blower door to properly rewire

unit.

374RAN