2

3

in.

19

in.

(483 mm)

20

in.

(508 mm)

20

in. (51 mm)

19

2

in. (51 mm)

PULL

OIL INLET

(BOTH SIDES)

VENT CONN

ELECTRICAL

CONNECTIONS

(BOTH SIDES)

.88 DIAM TYP

KNOCK-OUT BOTH SIDES

FOR

J

DIAM VENT

TOP KNOCK-OUT

FOR

J

DIAM VENT

A

E

G

B

L

H

C

D

F

K

(483 mm)

(76 mm)

A98037

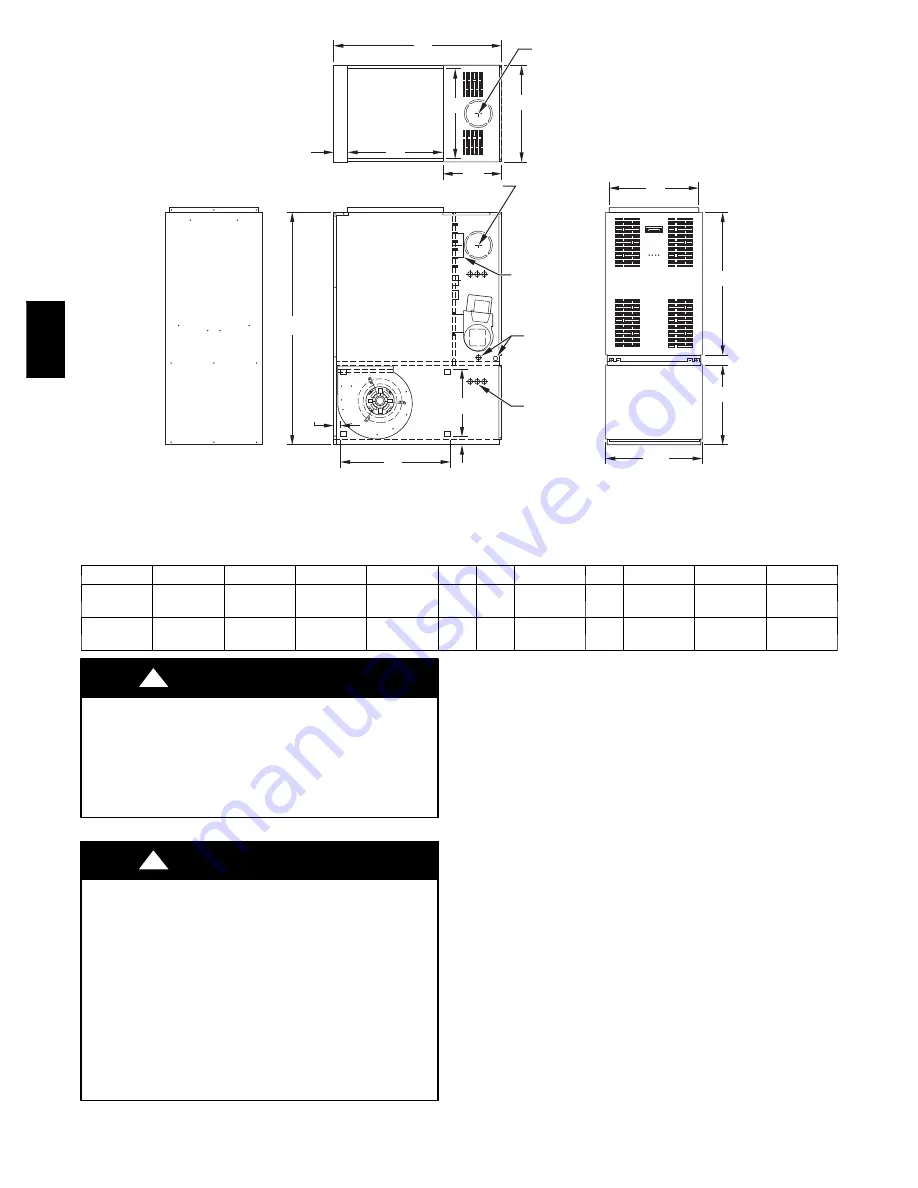

Fig. 2 -- Dimensional Drawing

DIMENSIONS -- IN. (MM)

UNIT SIZE

A

B

C

D

E

F

G

H

J

K

L

036105

35

(889)

48---3/4

(1238)

30---1/4

(768)

16---5/8

(422)

20

(508)

22

(559)

12

(305)

14

(356)

5

(127)

1---1/2

(38)

1---3/4

(44)

060120

39---1/2

(1003)

53

(1346)

32---1/4

(819)

18---3/4

(476)

24

(610)

28

(711)

12---3/8

(310)

16

(406)

6

(152)

1---5/8

(41)

1---1/2

(38)

FIRE, EXPLOSION, ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

These instructions are intended to be used by qualified

personnel who have been trained in installing this type of

furnace.

!

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. Do not

attempt to start the burner when excess oil has accumulated,

when the furnace is full of vapor, or when the combustion

chamber is very hot.

For use with grade 1 or 2 fuel oil. Do not use gasoline,

crankcase oil, or any oil containing gasoline!

Never burn garbage or paper in the heating system and never

leave rags, paper, or any flammable items around the unit.

!

WARNING

All local and national code requirements governing installation of

oil burning equipment, wiring, and flue connections must be

followed. Some of the codes (issued by the Canadian Standards

Association, the National Fire Protection Agency, and/or the

American National Standards Institute) that may be applicable are:

ANSI/NFPA 31: INSTALLATION OF OIL BURNING

EQUIPMENT

ANSI/NFPA 211: CHIMNEYS, FIREPLACES, VENTS, AND

SOLID FUEL BURNING APPLIANCES

ANSI/NFPA 90B: WARM AIR HEATING AND AIR

CONDITIONING SYSTEMS

ANSI/NFPA 70: NATIONAL ELECTRIC CODE

CSA B139: INSTALLATION CODE FOR OIL BURNING

EQUIPMENT

CAS C22.1: CANADIAN ELECTRICAL CODE

US and CANADA: Current edition of SMACNA and NFPA 90B

as tested by UL Standard 181 for Class I Rigid Air Ducts

Only the latest issues of these codes should be used, and are

available from either: The National Fire Protection Agency,

Batterymarch Park, Quincy, MA 02269, or The Canadian

Standards Association, 178 Rexdale Blvd., Rexdale, Ontario

M9W1R3.

This furnace is designed for continuous return--air minimum

temperature of 60

_

F/15

_

C db or intermittent operation down to

55

_

F/13

_

C db such as when used with a night setback thermostat.

Return--air temperature must not exceed 80

_

F/27

_

C db. Failure to

follow these return air limits may affect reliability of heat

exchangers, motors and controls. (See Fig. 3.)

374RAN