22

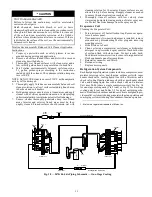

Fig. 38 — Typical Location of Heater Limit Switches

(3

-

phase heater shown)

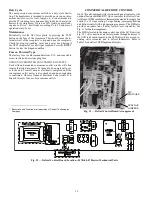

Completing Heater Installation

FIELD POWER CONNECTIONS

Tap conductors must be installed between the base unit’s field

power connection lugs and the single point box (with or with

-

out fuses). See Fig. 39. Refer to unit wiring schematic. Use

copper wire only. For connection using the single point box

without fuses, connect the field power supply conductors to the

heater power leads and the field-supplied tap conductors inside

the single point box. Use UL-approved pressure connectors

(field-supplied) for these splice joints.

LOW-VOLTAGE CONTROL CONNECTIONS

Pull the low-voltage control leads from the heater module(s) —

ORN, VIO and BRN — to the 4-pole terminal board TB4 lo

-

cated on the heater bulkhead to the left of heater 1. Connect the

ORN lead to terminal TB4-1. Connect the VIO lead to terminal

TB4-2. Connect the BRN lead to terminal TB4-3. See Fig. 39.

T

Fig. 39 — Accessory Electric Heater Control Connections

SMOKE DETECTORS

Smoke detectors are available as factory-installed options on

547K models. Smoke detectors may be specified for supply air

only, for return air without or with economizer, or in combina

-

tion of supply air and return air. Return air smoke detectors are

arranged for vertical return configurations only. All compo

-

nents necessary for operation are factory-provided and mount

-

ed. The unit is factory-configured for immediate smoke detec

-

tor shutdown operation; additional wiring or modifications to

unit terminal board may be necessary to complete the unit and

smoke detector configuration to meet project requirements.

System

The smoke detector system consists of a four-wire controller and

one or two sensors. Its primary function is to shut down the roof

-

top unit in order to prevent smoke from circulating throughout

the building. It is not to be used as a life saving device.

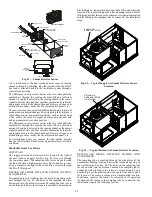

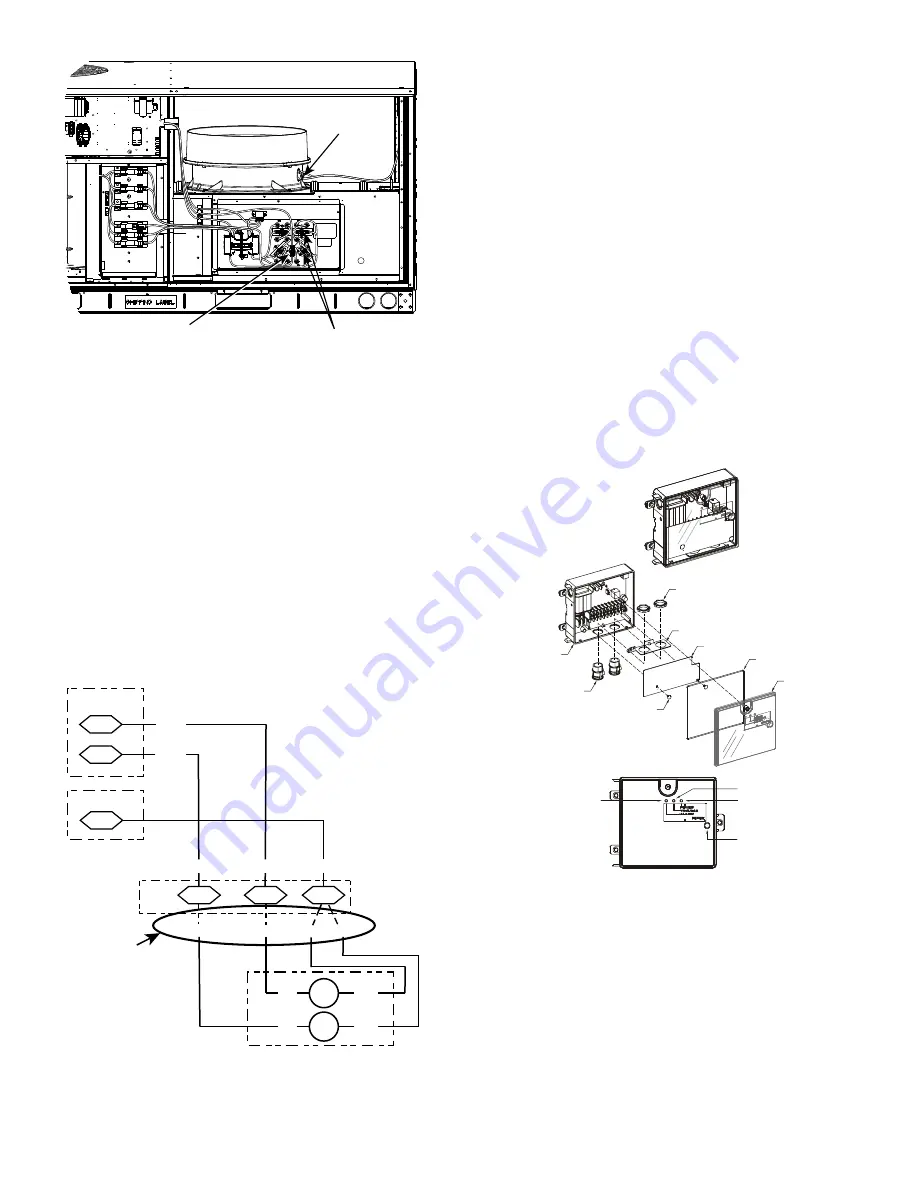

Controller

The controller (see Fig. 40) includes a controller housing, a

printed circuit board, and a clear plastic cover. The controller

can be connected to one or two compatible duct smoke sensors.

The clear plastic cover is secured to the housing with a single

captive screw for easy access to the wiring terminals. The con

-

troller has three LEDs (for Power, Trouble and Alarm) and a

manual test/reset button (on the cover face).

Fig. 40 — Controller Assembly

Smoke Detector Sensor

The smoke detector sensor (see Fig. 41) includes a plastic

housing, a printed circuit board, a clear plastic cover, a sam

-

pling tube inlet and an exhaust tube. The sampling tube (when

used) and exhaust tube are attached during installation. The

sampling tube varies in length depending on the size of the

rooftop unit. The clear plastic cover permits visual inspections

without having to disassemble the sensor. The cover attaches to

the sensor housing using four captive screws and forms an air

-

tight chamber around the sensing electronics. Each sensor in

-

cludes a harness with an RJ45 terminal for connecting to the

controller. Each sensor has four LEDs (for Power, Trouble,

Alarm and Dirty) and a manual test/reset button (on the left-

side of the housing).

CONTROL SIDE

AUTOMATIC RESET

LIMIT SWITCHES

STATOR MANUAL

RESET LIMIT

SWITCH

LINE BREAK

"ONE SHOT"

LIMIT SWITCHES

VIO

HR1

BRN

UCB

Field

Connections

HR1: Heater Circuit 1

HR2: Heater Circuit 2

(if two-circuit module installed)

2

3

C

1

3

PNK

ORN

ORN

PNK

BRN

VIO

BRN BRN

VIO

2

TB4

VIO

HR2

BRN

Elec Htr

TRAN 1

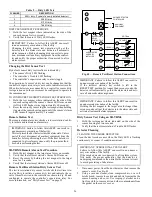

DUCT SMOKE SENSOR

CONTROLLER

CONDUIT NUT

S

(

S

UPPLIED BY IN

S

TALLER)

CONDUIT

S

UPPORT PLATE

TERMINAL BLOCK COVER

COVER GA

S

KET

(ORDERING OPTION)

CONTROLLER

COVER

FA

S

TENER (2X)

CONDUIT COUPLING

S

(

S

UPPLIED BY IN

S

TALLER)

CONTROLLER HOU

S

ING

AND ELECTRONIC

S

ALARM

TROUBLE

POWER

TE

S

T/RE

S

ET

S

WITCH