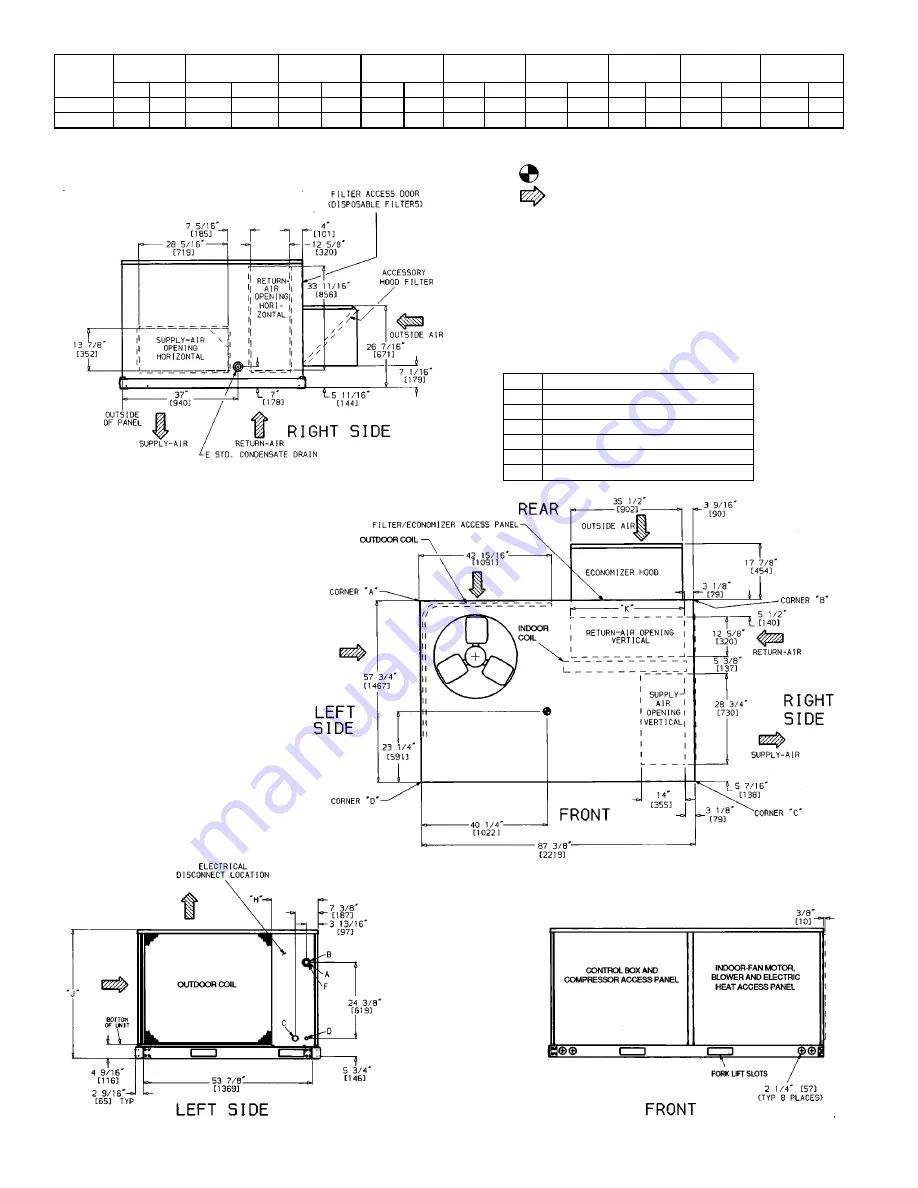

UNIT

STD UNIT

ECONOMIZER

CORNER

CORNER

CORNER

CORNER

‘‘H’’

‘‘J’’

‘‘K’’

WEIGHT

WEIGHT

WEIGHT (A)

WEIGHT (B)

WEIGHT (C)

WEIGHT (D)

Lb

Kg

Lb

Kg

Lb

Kg

Lb

Kg

Lb

Kg

Lb

Kg

In.

mm

In.

mm

In.

mm

548C090

840

381

44

20

182

83

156

71

231

105

271

123

24

7

⁄

8

632

41

5

⁄

16

1050

33

11

⁄

16

856

548C120

940

426

44

20

204

93

174

79

259

117

303

137

14

7

⁄

8

378

49

5

⁄

16

1253

36

3

⁄

8

924

NOTES:

1. Dimensions in [

] are in millimeters.

2.

Center of gravity.

3.

Direction of airflow.

4. Ductwork to be attached to accessory roof curb only.

5. Minimum clearance (local codes or jurisdiction may prevail):

a. Bottom to combustible surfaces (when not using curb) 1 inch.

b. Outdoor coil, for proper airflow, 915 mm (36 in.) 1 side, 305 mm (12

in.) the other. The side getting the greater clearance is optional.

c. Overhead, 1525 mm (60 in.) to assure proper outdoor fan

operation.

d. Between units, control box side, 1065 mm (42 in.).

e. Between unit and ungrounded surfaces, control box side, 915 mm

(36 in.).

f. Between unit and block or concrete walls and other grounded sur-

faces, control box side, 1065 mm (42 in.).

g. Horizontal supply and return end, zero mm (zero in.).

6. With the exception of the clearance for the outdoor coil as stated in

Notes 5b and c, a removable fence or barricade requires no clearance.

CONNECTION SIZES

A

1

3

⁄

8

9

Dia [35] Field Power Supply Hole

B

2

1

⁄

2

9

Dia [64] Power Supply Knockout

C

1

3

⁄

4

9

Dia [44] Charging-Port Hole

D

7

⁄

8

9

Dia [22] Field Control Wiring Hole

E

3

⁄

4

9

-14 NPT Condensate Drain

F

2

9

Dia [51] Power Supply Knockout

Fig. 2 — Base Unit Dimensions

—2—