548J

SINGLE PACKAGE HEAT PUMP/ELECTRIC HEAT

NOMINAL 3 TO 8.5 TONS

WITH PURON

R

(R--410A) REFRIGERANT

Service and Maintenance Instructions

TABLE OF CONTENTS

SAFETY CONSIDERATIONS

1

. . . . . . . . . . . . . . . . . . . .

UNIT ARRANGEMENT AND ACCESS

3

. . . . . . . . . . .

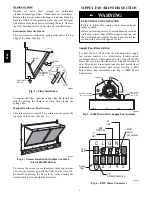

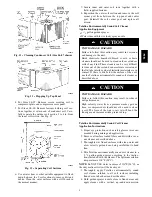

SUPPLY FAN (BLOWER) SECTION

4

. . . . . . . . . . . . . .

HEAT PUMP REFRIGERATION SYSTEM

8

. . . . . . . . .

PURON

R

(R--410A) REFRIGERANT

13

. . . . . . . . . . . . .

COOLING CHARGING CHARTS

14

. . . . . . . . . . . . . . . .

CONVENIENCE OUTLETS

19

. . . . . . . . . . . . . . . . . . . .

HEAT PUMP CONTROLS

20

. . . . . . . . . . . . . . . . . . . . . .

PROTECTIVE CONTROLS

20

. . . . . . . . . . . . . . . . . . . . .

COMMERCIAL DEFROST CONTROL

21

. . . . . . . . . . .

ELECTRIC HEATERS

24

. . . . . . . . . . . . . . . . . . . . . . . . .

SMOKE DETECTORS

26

. . . . . . . . . . . . . . . . . . . . . . . . .

RTU--MP CONTROL SYSTEM

33

. . . . . . . . . . . . . . . . . .

ECONOMIZER SYSTEMS

47

. . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAMS

56

. . . . . . . . . . . . . . . . . . . . . . . . .

PRE--START-UP

58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START-UP, GENERAL

58

. . . . . . . . . . . . . . . . . . . . . . . . .

START-UP, RTU--MP CONTROL

59

. . . . . . . . . . . . . . . .

OPERATING SEQUENCE

62

. . . . . . . . . . . . . . . . . . . . . .

FASTENER TORQUE VALUES

67

. . . . . . . . . . . . . . . . .

APPENDIX I. MODEL NUMBER SIGNIFICANCE

68

. . .

APPENDIX II. PHYSICAL DATA

69

. . . . . . . . . . . . . . . .

APPENDIX III. FAN PERFORMANCE

71

. . . . . . . . . . .

APPENDIX IV. ELECTRICAL INFORMATION

82

. . . .

APPENDIX V. WIRING DIAGRAM LIST

96

. . . . . . . . .

APPENDIX VI. MOTORMASTER SENSOR

LOCATIONS

97

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT START-UP CHECKLIST

99

. . . . . . . . . . . . . . . . . .

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install, repair, or service air-conditioning

equipment. Untrained personnel can perform the basic

maintenance functions of replacing filters. Trained service

personnel should perform all other operations.

When working on air-conditioning equipment, observe

precautions in the literature, tags and labels attached to

the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations.

Have fire extinguishers available for all brazing

operations.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions attached to

the unit. Consult local building codes and National

Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety--alert

symbol

. When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for

personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety--alert

symbol. DANGER identifies the most serious hazards

which

will

result in severe personal injury or death.

WARNING signifies a hazard which

could

result in

personal injury or death. CAUTION is used to identify

unsafe practices which

may

result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which

will

result in enhanced

installation, reliability, or operation.