3. Use only copper or copper-clad conductor for connec-

tions between field-supplied electrical disconnect switch

and unit. The use of aluminum wire is not recom-

mended. Maximum wire size is number 2 AWG (Ameri-

can Wire Gage) on units without heat. The maximum

wire size is number 2/0 AWG on units with heat.

4. Units with accessory electric heat must also have the

correct single point box kit to meet UL (Underwriters’

Laboratories) requirements. Refer to installation instruc-

tions shipped with the accessory for more details.

5. Voltage to compressor terminals during operation must

be within voltage range indicated on unit nameplate (also

see Tables 2A and 2B). On 3-phase units, voltages be-

tween phases must be balanced within 2% and the cur-

rent within 10%. Use the formula shown in Tables 2A-

2B, Note 2 to determine the percent voltage imbalance.

Operation on improper line voltage or excessive phase

imbalance constitutes abuse and may cause damage to

electrical components. Such operation would invalidate

any applicable warranty.

6. Insulate low-voltage wires for highest voltage con-

tained within conduit when low-voltage control wires are

run in same conduit as high-voltage wires. Install con-

duit through side panel openings. For units without ac-

cessory electric heat, install conduit between disconnect

and control box.

7. Do not damage internal components when drilling through

any panel to mount electrical hardware, conduit, etc.

8. Install power lines to terminal connections as shown in

Fig. 10.

9. For units with accessory electric heat, refer to accessory

electric heat installation instructions for power wiring.

High-Voltage Connections

The unit must have a separate electrical service with a field-

supplied, waterproof, fused, disconnect switch mounted at, or

within sight of, the unit. Refer to the unit rating plate for

maximum fuse/circuit breaker size and minimum circuit amps

(ampacity) for wire sizing. Be sure disconnect switch does not

obstruct unit rating plate.

The field-supplied disconnect switch box may be mounted on

the unit over the high-voltage inlet hole in the control corner

panel. A factory-installed disconnect switch is available.

Proceed as follows to complete the high-voltage connections

to the unit:

1. Connect ground lead to chassis ground connection when

using separate ground wire.

2. Pigtails are provided for field power connections. Use

factory-supplied splices or UL-approved copper/aluminum

connector. Install conduit connectors in side panel power

supply knockout openings indicated in Fig. 2. Route power

lines through connector to unit control box.

NOTE:

If accessory thru-the-bottom connections are used, re-

fer to the thru-the-bottom accessory installation instructions

for information on wiring the unit. Refer to Fig. 2 for loca-

tions to drill holes through the basepan.

Special Procedures for 208-V Operation

DANGER:

Make sure that the power supply to the

unit is switched OFF before making any wiring changes.

Electrical shock can cause personal injury or death.

For operation on 208 v, disconnect the black wire from the

230-v orange wire on the transformer and connect it to the

200-v red wire from the transformer. Insulate the end of the

orange wire.

Control Voltage Connection

Install a factory-approved room thermostat. See Table 3.

Locate the thermostat on an inside wall in the space to be

conditioned where it will not be subjected to either a cooling

or heating source or direct exposure to sunlight. Mount the

thermostat 4 to 5 ft above the floor.

NOTE:

For wire runs up to 50 ft, use number 18 AWG insu-

lated wire (35 C minimum). For 51 to 75 ft, use number

16 AWG insulated wire (35 C minimum). For 76 to 150 ft, use

number 14 AWG insulated wire (35 C minimum). All wire larger

than number 18 AWG cannot be connected directly to the ther-

mostat and will require a junction box and splice at the

thermostat.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals to low-voltage connections on

unit (shown in Fig. 11) as described in Steps 1 through 3

below.

1. Connect thermostat wires to screw terminals of low volt-

age connection board.

2. Pass the control wires through the hole provided in the

corner post.

3. Feed wire through the raceway built into the corner post

to the 24-v barrier located on the left side of the control

box. See Fig. 12. The raceway provides the UL-required

clearance between the high- and low-voltage wiring.

Heat Anticipator Setting

The room thermostat heat anticipator must be adjusted prop-

erly to ensure proper heating performance. Set the heat an-

ticipator using an ammeter to determine the exact required

setting.

NOTE:

For thermostat selection purposes, set first-stage heat

anticipator setting at 0.8 and set second-stage heat anticipa-

tor setting at 0.3.

Failure to make a proper heat anticipator adjustment may

result in improper operation, discomfort to the occupants of

the conditioned space and inefficient energy utilization; how-

ever, the required setting may be changed slightly to provide

a greater degree of comfort for a particular installation.

—8—

Summary of Contents for 551B Series

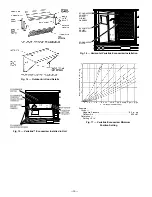

Page 32: ...Fig 34 Cooling Charging Chart 551B060 Fig 35 Cooling Chart Chart 551B072 32 ...

Page 37: ......

Page 38: ......

Page 39: ......