16

LOW VOLTAGE

CONDUIT

CONNECTOR

HIGH VOLTAGE

CONDUIT

CONNECTOR

C08637

Fig. 21 -- Thru--Base Connection Fittings

Check tightness of connector lock nuts before connecting

electrical conduits.

Field--supplied and field--installed liquidtight conduit

connectors and conduit may be attached to the connectors

on the basepan. Pull correctly rated high voltage and low

voltage through appropriate conduits. Connect the power

conduit to the internal disconnect (if unit is so equipped)

or to the external disconnect (through unit side panel). A

hole must be field cut in the main control box bottom on

the left side so the 24--v control connections can be made.

Connect the control power conduit to the unit control box

at this hole.

Units without Thru--Base Connections —

1. Install power wiring conduit through side panel open-

ings. Install conduit between disconnect and control

box.

2. Install power lines to terminal connections as shown

in Fig. 17.

All Units —

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate. See

Table 5. On 3--phase units, voltages between phases must

be balanced within 2% and the current within 10%. Use

the formula shown in the legend for Table 5, Note 2 (see

page 39) to determine the percent of voltage imbalance.

Operation on improper line voltage or excessive phase

imbalance constitutes abuse and may cause damage to

electrical components. Such operation would invalidate

any applicable Bryant warranty.

Field Control Wiring —

The 558J***D unit requires an external temperature

control device. This device can be a thermostat emulation

device provided as part of a third--party Building

Management System.

Thermostat —

Install a Bryant--approved accessory thermostat according

to installation instructions included with the accessory.

For complete economizer function, select a two--stage

cooling thermostat. Locate the thermostat accessory on a

solid wall in the conditioned space to sense average

temperature in accordance with the thermostat installation

instructions.

If the thermostat contains a logic circuit requiring 24--v

power, use a thermostat cable or equivalent single leads of

different colors with minimum of seven leads. If the

thermostat does not require a 24--v source (no “C”

connection required), use a thermostat cable or equivalent

with minimum of six leads. Check the thermostat

installation instructions for additional features which

might require additional conductors in the cable.

For wire runs up to 50 ft. (15 m), use no. 18 AWG

(American Wire Gage) insulated wire (35

_

C minimum).

For 50 to 75 ft. (15 to 23 m), use no. 16 AWG insulated

wire (35

_

C minimum). For over 75 ft. (23 m), use no. 14

AWG insulated wire (35

_

C minimum). All wire sizes

larger than no. 18 AWG cannot be directly connected to

the thermostat and will require a junction box and splice

at the thermostat.

Unit without thru--base connection kit —

Pass the thermostat control wires through the hole

provided in the end panel (see item “D” in the view

labeled “LEFT” in Fig. 1 & 2); then feed the wires

through the raceway built into the corner post to the

control box. Pull the wires over to the terminal strip on the

upper--left corner of the Central Ternimal Board (CTB).

See Fig. 22.

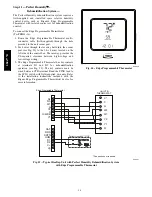

Typical

Thermostat

Connections

Central

Terminal

Board

W1

Y2

Y1

R

W2

G

C

X

W1

Y2

Y1

R

W2

G

C

X

T–STAT

C

W2

G

W1

O/B/Y2

R

Y1

(Note 1)

Note 1: Typical multi-function marking. Follow manufacturer’s configuration

instructions to select Y2.

Note 2: W2 connection not required on units with single-stage heating.

Field Wiring

(Note 2)

C09351

Fig. 22 -- Typical Low--Voltage Control Connections

558J

***D