28

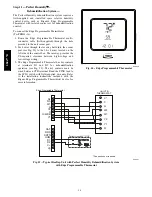

Duct smoke sensor

controller

Fastener

(2X)

Controller cover

Conduit nuts

(supplied by installer)

Conduit support plate

Cover gasket

(ordering option)

Conduit couplings

(supplied by installer)

Terminal block cover

Controller housing

and electronics

Alarm

Power

Test/reset

switch

Trouble

C08208

Fig. 47 -- Controller Assembly

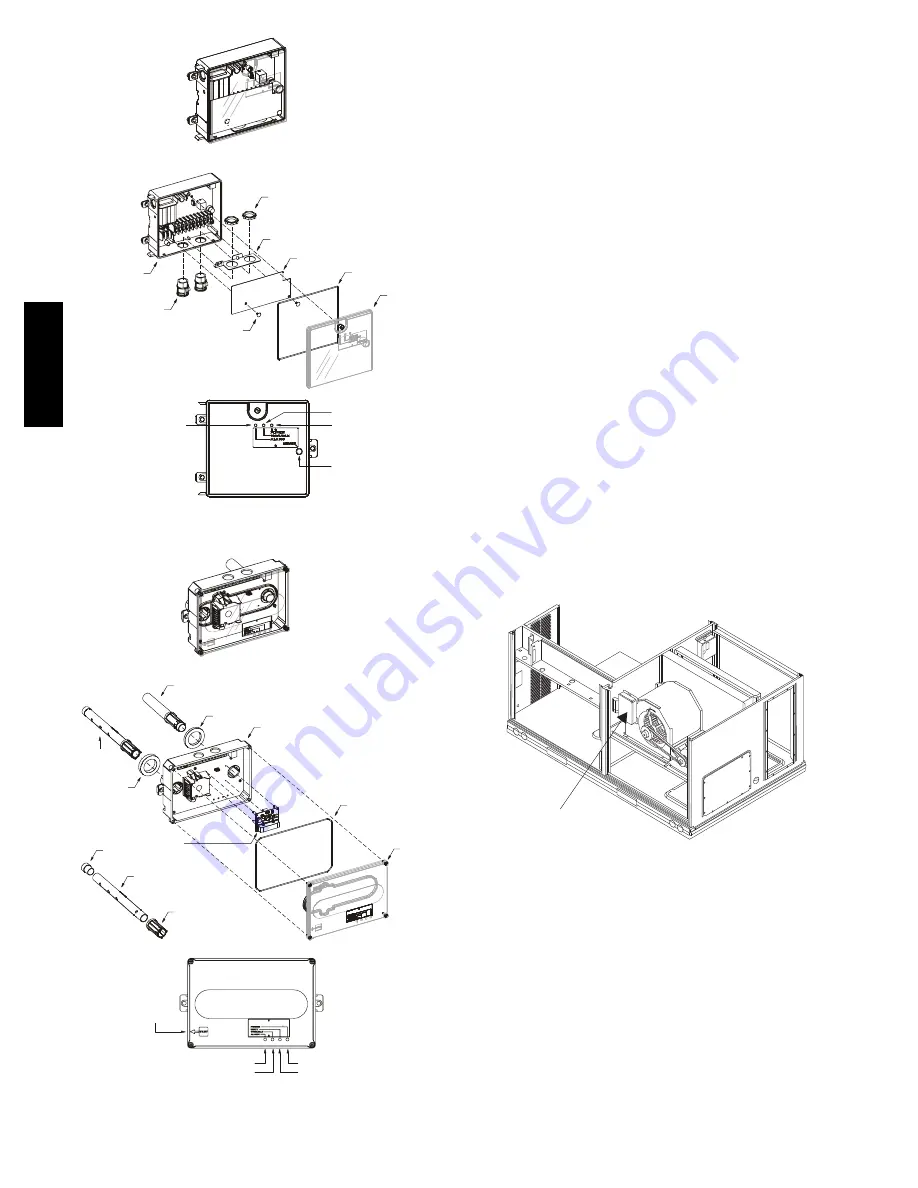

Duct smoke sensor

See

Detail A

Exhaust tube

Plug

Sampling tube

(ordered separately)

Intake

gasket

Cover gasket

(ordering option)

TSD-CO2

(ordering option)

Sensor housing

and electronics

Exhaust gasket

Coupling

Sensor cover

Detail A

Magnetic

test/reset

switch

Alarm

Trouble

Power

Dirty

C08209

Fig. 48 -- Smoke Detector Sensor

Air is introduced to the duct smoke detector sensor’s

sensing chamber through a sampling tube that extends into

the HVAC duct and is directed back into the ventilation

system through a (shorter) exhaust tube. The difference in

air pressure between the two tubes pulls the sampled air

through the sensing chamber. When a sufficient amount of

smoke is detected in the sensing chamber, the sensor

signals an alarm state and the controller automatically

takes the appropriate action to shut down fans and

blowers, change over air handling systems, notify the fire

alarm control panel, etc.

The sensor uses a process called differential sensing to

prevent gradual environmental changes from triggering

false alarms. A rapid change in environmental conditions,

such as smoke from a fire, causes the sensor to signal an

alarm state but dust and debris accumulated over time

does not.

For installations using two sensors, the duct smoke

detector does not differentiate which sensor signals an

alarm or trouble condition.

Smoke Detector Locations

Supply Air — The Supply Air smoke detector sensor is

located to the left of the unit’s indoor (supply) fan. See

Fig. 49. Access is through the fan access panel. There is

no sampling tube used at this location. The sampling tube

inlet extends through the side plate of the fan housing

(into a high pressure area). The controller is located on a

bracket to the right of the return filter, accessed through

the lift--off filter panel.

Smoke Detector Sensor

C08245

Fig. 49 -- Typical Supply Air Smoke Detector Sensor

Location

Return Air without Economizer — The sampling tube is

located across the return air opening on the unit basepan.

See Fig. 50. The holes in the sampling tube face

downward, into the return air stream. The sampling tube is

connected via tubing to the return air sensor that is

mounted on a bracket high on the partition between return

filter and controller location. (This sensor is shipped in a

flat--mounting location. Installation requires that this

sensor be relocated to its operating location and the tubing

to the sampling tube be connected. See “

Completing

Installation of Return Air Smoke Sensor

:” on page 29

for details.)

558J

***D