33

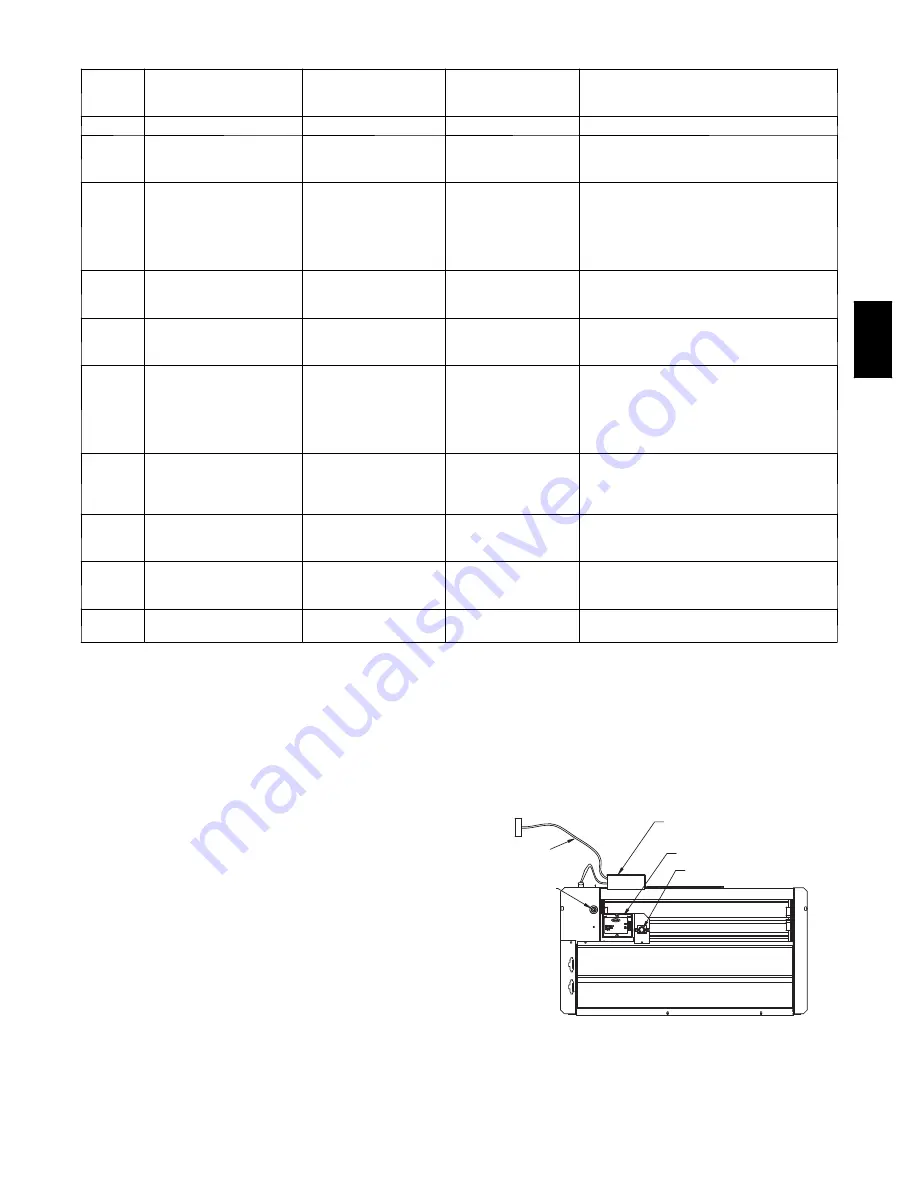

Table 14 – IGC Board LED Alarm Codes

LED

FLASH

CODE

DESCRIPTION

ACTION TAKEN BY

CONTROL

RESET METHOD

PROBABLE CAUSE

On

Normal Operation

—

—

—

Off

Hardware Failure

No gas heating.

—

Loss of power to the IGC. Check 5 amp fuse

on IGC, power to unit, 24V circuit breaker,

transformer, and wiring to the IGC.

2 Flashes Limit Switch Fault

Gas valve and igniter Off.

Indoor fan and inducer

On.

Limit switch closed, or

heat call (W) Off.

High temperature limit switch is open. Check

the operation of the indoor (evaporator) fan

motor.

Ensure that the supply-air temperature rise is

within the range on the unit nameplate. Check

wiring and limit switch operation.

3 Flashes Flame Sense Fault

Indoor fan and inducer

On.

Flame sense normal.

Power reset for LED

reset.

The IGC sensed a flame when the gas valve

should be closed. Check wiring, flame sensor,

and gas valve operation.

4 Flashes Four Consecutive Limit

Switch Fault

No gas heating.

Heat call (W) Off.

Power reset for LED

reset.

4 consecutive limit switch faults within a single

call for heat. See Limit Switch Fault.

5 Flashes Ignition Fault

No gas heating.

Heat call (W) Off.

Power reset for LED

reset.

Unit unsuccessfully attempted ignition for 15

minutes. Check igniter and flame sensor elec-

trode spacing, gaps, etc. Check flame sense

and igniter wiring. Check gas valve operation

and gas supply. Check gas valve connections

to IGC terminals. BRN lead must be on Pin 11.

6 Flashes Induced Draft Motor Fault

If heat off: no gas

heating.

If heat on: gas valve Off

and inducer On.

Inducer sense normal,

or heat call (W) Off.

Inducer sense On when heat call Off, or induc-

er sense Off when heat call On. Check wiring,

voltage, and operation of IGC motor. Check

speed sensor wiring to IGC.

7 Flashes Rollout Switch Lockout

Gas valve and igniter Off.

Indoor fan and inducer

On.

Power reset.

Rollout switch has opened. Check gas valve

operation. Check induced-draft blower wheel is

properly secured to motor shaft.

8 Flashes Internal Control Lockout

No gas heating.

Power reset.

IGC has sensed internal hardware or software

error. If fault is not cleared by resetting 24 v

power, replace the IGC.

9 Flashes Temporary Software

Lockout

No gas heating.

1 hour auto reset, or

power reset.

Electrical interference is disrupting the IGC

software.

LEGEND

IGC

--- Integrated Gas Unit Control

LED

--- Light---Emitting Diode

NOTES

:

1. There is a 3---second pause between alarm code displays.

2. If more than one alarm code exists, all applicable alarm codes will be displayed in numerical sequence.

3. Alarm codes on the IGC will be lost if power to the unit is interrupted.

ECONOMIZER SYSTEMS

The 580J units may be equipped with a factory--installed

or accessory (field--installed) economizer system. Two

types are available: with a logic control system

(EconoMi$er IV) and without a control system

(EconoMi$er2). See Fig. 39 and Fig. 40 for component

locations on each type. See Fig. 41 and Fig. 42 for

economizer section wiring diagrams.

Both economizers use direct--drive damper actuators.

ECONOMI$ER IV

CONTROLLER

OUTSIDE AIR

TEMPERATURE SENSOR

LOW AMBIENT

SENSOR

ACTUATOR

WIRING

HARNESS

C06021

Fig. 39 -- EconoMi$er IV Component Locations

580J

Summary of Contents for 580J*04--12

Page 9: ...9 COOLING CHARGING CHARTS C08203 C08204 Fig 12 Cooling Charging Charts 580J ...

Page 10: ...10 COOLING CHARGING CHARTS cont C08228 C08229 Fig 12 Cooling Charging Charts cont 580J ...

Page 11: ...11 COOLING CHARGING CHARTS cont C08437 C08438 Fig 12 Cooling Charging Charts cont 580J ...

Page 12: ...12 COOLING CHARGING CHARTS cont C08439 Fig 12 Cooling Charging Charts cont 580J ...

Page 46: ...46 C08308 Fig 52 580J Typical Unit Wiring Diagram Power 06A B C 208 230 3 60 580J ...

Page 47: ...47 C08317 Fig 53 580J Unit Wiring Diagram Control 06A B C 580J ...