60

START-UP CHECKLIST

(Remove and Store in Job File)

I. PRELIMINARY INFORMATION

MODEL NO.:

SERIAL NO.:

DATE:

TECHNICIAN:

II. PRE-START-UP (insert checkmark in box as each item is completed)

j

VERIFY THAT JOBSITE VOLTAGE AGREES WITH VOLTAGE LISTED ON RATING PLATE

j

VERIFY THAT ALL PACKAGING MATERIALS HAVE BEEN REMOVED FROM UNIT

j

REMOVE ALL SHIPPING HOLDDOWN BOLTS AND BRACKETS PER INSTALLATION INSTRUCTIONS

j

VERIFY THAT CONDENSATE CONNECTION IS INSTALLED PER INSTALLATION INSTRUCTIONS

j

CHECK ALL ELECTRICAL CONNECTIONS AND TERMINALS FOR TIGHTNESS

j

CHECK GAS PIPING FOR LEAKS

j

CHECK THAT RETURN (INDOOR) AIR FILTERS ARE CLEAN AND IN PLACE

j

VERIFY THAT UNIT INSTALLATION IS LEVEL

j

CHECK FAN WHEELS AND PROPELLER FOR LOCATION IN HOUSING/ORIFICE AND SETSCREW

TIGHTNESS

j

CHECK TO ENSURE THAT ELECTRICAL WIRING IS NOT IN CONTACT WITH REFRIGERANT LINES

OR SHARP METAL EDGES

j

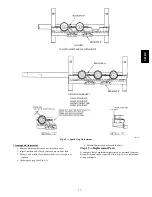

CHECK PULLEY ALIGNMENT AND BELT TENSION PER INSTALLATION INSTRUCTIONS

III. START-UP

ELECTRICAL

SUPPLY VOLTAGE

L1-L2

L2-L3

L3-L1

COMPRESSOR AMPS

L1

L2

L3

INDOOR-FAN AMPS

L1

L2

L3

TEMPERATURES

OUTDOOR-AIR TEMPERATURE

DB

RETURN-AIR TEMPERATURE

DB

WB

COOLING SUPPLY AIR

DB

HEATING SUPPLY AIR

DB

PRESSURES (Cooling Mode)

GAS INLET PRESSURE

IN.WG

GAS MANIFOLD PRESSURE

IN.WG (HIGH FIRE)

REFRIGERANT SUCTION

PSIG

REFRIGERANT DISCHARGE

PSIG

j

VERIFY THAT 3-PHASE FAN MOTOR AND BLOWER ARE ROTATING IN CORRECT DIRECTION. IF THEY

ARE NOT ROTATING IN CORRECT DIRECTION, LOCKING COLLAR MUST BE RE--TIGHTENED AFTER

CORRECTING DIRECTION OF ROTATION

j

VERIFY THAT 3-PHASE SCROLL COMPRESSOR IS ROTATING IN THE CORRECT DIRECTION

j

VERIFY REFRIGERANT CHARGE USING CHARGING CHARTS

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

E

2007 Bryant Heating & Cooling Systems 7310 W. Morris St. Indianapolis, IN 46231

Printed in U.S.A.

Edition Date: 2/07

Replaces: II 581B--- 36--- 7

Catalog No. II581B---C---36---1

581B

,C