2

TABLE OF CONTENTS

PAGE

FEATURES AND BENEFITS

3

. . . . . . . . . . . . . . . . . . . .

MODEL NUMBER NOMENCLATURE

4

. . . . . . . . . . . .

FACTORY OPTIONS AND/OR ACCESSORIES

6

. . . . .

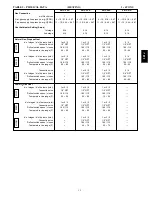

AHRI COOLING RATING TABLES

8

. . . . . . . . . . . . . . .

HEAT RATING TABLE

9

. . . . . . . . . . . . . . . . . . . . . . . . .

SOUND PERFORMANCE TABLE

10

. . . . . . . . . . . . . . .

PHYSICAL DATA

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CURBS & WEIGHTS DIMENSIONS

16

. . . . . . . . . . . . .

APPLICATION DATA

23

. . . . . . . . . . . . . . . . . . . . . . . . .

PAGE

SELECTION PROCEDURE

25

. . . . . . . . . . . . . . . . . . . . .

COOLING TABLES

26

. . . . . . . . . . . . . . . . . . . . . . . . . . .

STATIC PRESSURE ADDERS

32

. . . . . . . . . . . . . . . . . .

FAN PERFORMANCE

33

. . . . . . . . . . . . . . . . . . . . . . . . .

OUTDOOR AIR INTAKE & EXHAUST PERF

43

. . . . .

ELECTRICAL INFORMATION

44

. . . . . . . . . . . . . . . . .

MCA/MOCP

46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TYPICAL WIRING DIAGRAMS

51

. . . . . . . . . . . . . . . .

SEQUENCE OF OPERATION

55

. . . . . . . . . . . . . . . . . . .

GUIDE SPECIFICATIONS

57

. . . . . . . . . . . . . . . . . . . . . .

Your Bryant rooftop unit (RTU) was designed by customers for customers. With “no--strip screw” collars, handled access

panels, and more we’ve made your unit easy to install, easy to maintain and easy to use.

Easy to install:

All Preferred Series

t

units are field--convertible to horizontal air flow; no special adapter curbs or kits are necessary.

Convertible airflow design makes it easy to adjust to unexpected job--site complications. Lighter units make easy

replacement. Bryant 3--8.5 ton 581J rooftops fit on existing Bryant curbs dating back to 1989. Also, our large control box

gives you room to work and room to mount Bryant accessory controls.

Easy to maintain:

Easy access handles by Bryant provide quick and easy access to all normally serviced components. Our “no--strip” screw

system has superior holding power and guides screws into position while preventing the screw from stripping the unit’s

metal. Take accurate pressure readings by reading condenser pressure with panels on. Simply remove the black, composite

plug, route your gauge line(s) through the hole, and connect them to the refrigeration service valve(s). Now, you can take

refrigeration system pressure readings without affecting the condenser airflow.

Easy to use:

The newly designed, master terminal board by Bryant puts all your connections and troubleshooting points in one

convenient place, standard. Most low voltage connections are made to the same board and make it easy to find what you’re

looking for and easy to access it. Bryant rooftops have high and low pressure switches, a filter drier, and 2” (51mm) filters

standard.

the environmentally sound refrigerant

581J

Summary of Contents for 581J

Page 51: ...51 TYPICAL WIRING DIAGRAMS C08518 Fig 15 1 Stage Cooling Typical Power Diagram 581J ...

Page 52: ...52 TYPICAL WIRING DIAGRAMS cont C08577 Fig 16 2 Stage Cooling Typical Power Diagram 581J ...

Page 53: ...53 C08524 Fig 17 1 Stage Typical Wiring Diagram 581J ...

Page 54: ...54 C08578 Fig 18 2 Stage Typical Wiring Diagram 581J ...