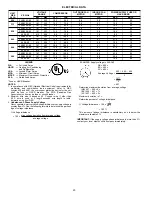

OPTIONS AND ACCESSORIES

FACTORY-INSTALLED OPTIONS

Louvered Grille provides hail and vandalism protection. See

model number nomenclature for louvered grille options.

Coil Options include copper/copper and vinyl-coated construc-

tion for refrigerant coils. Units are shipped standard with copper

tube/aluminum fin construction. See model number nomencla-

ture for coil options.

FIELD-INSTALLED ACCESSORIES

Economizer with Solid-State Controls and Barometric

Relief Dampers

Manual Air Damper (25% open)

Filter Rack

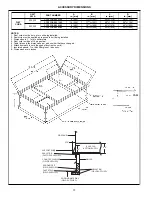

Flat Roof Curbs (8-in. and 14-in.)

Square-to-Round Duct Transition Kit

Thermostats

Controls Upgrade Kit

Crankcase Heater

Compressor Hard Start Kit (for use on single-phase units only)

LP Conversion Kit

High Altitude Kit

Low NO

x

Kit

Low Ambient Kit (Motormaster

T

II Control)

Solid-State Time Guard

T

II Device

Duct Conversion Kit (Horizontal to Vertical)

Economizer with Solid-State Controls and Barometric Re-

lief Dampers includes filter racks and provide outdoor air during

cooling and reduce compressor operation.

Manual Outside Air Damper includes hood and filter rack with

adjustable damper blade for up to 25% outdoor air.

Flat Roof Curbs in both 8 in. and 14 in. sizes are available for

roof mounted applications.

Square-to-Round Duct Transition Kit enables 024-048 size

units to be fitted to 14 in. round ductwork.

Compressor Hard Start Kit assists compressor start-up by

providing additional starting torque on single-phase units and

prolongs compressor motor life.

Duct Conversion Kit consists of 2 duct covers to be placed

over the horizontal supply and return duct openings when the

unit is converted for downshot applications.

Thermostats provide control for the system heating and cooling

functions. Thermostat models are available in both program-

mable and non-programmable versions.

Controls Upgrade Kit supplies high and low pressure safety

protection and protects the unit from operating in unsuitable

conditions.

Crankcase Heater provides anti-floodback protection for low-

load cooling applications.

LP (Liquid Propane) Conversion Kit allows for conversion

from natural gas to liquid propane fuel.

Low NO

x

Kit for use with units being installed in California Air

Quality Management Districts which require NO

x

emissions of

40 nanograms/joule or less.

Low-Ambient Kit (Motormaster II Control) allows the use

of mechanical cooling down to outdoor temperatures as low

as 0° F.

Solid-State Time Guard II Device provides short-cycling pro-

tection for the compressor. Not required with corporate elec-

tronic thermostats.

Filter Rack features easy installation, serviceability, and high-

filtering performance for vertical applications.

High Altitude Kit is for use at 2001 to 6000 ft above sea level.

Kit consists of natural gas orifices that compensate for gas heat

operation at high altitude.

6

Summary of Contents for 583A Series

Page 27: ......