Cancels: New

II 619F-18-1

4/1/06

installation, start-up and

service instructions

IN-CEILING CASSETTE

FAN COIL UNITS

619FNF

619FNQ

Sizes 018-03036

CONTENTS

Page

SAFETY CONSIDERATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

I. Step 1 — Complete Pre-Installation Checks

. . . . . . 2

II. Step 2 — Locating and Mounting the Unit

. . . . . . . . 6

III. Step 3 — Locating and Mounting the Room

Controller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

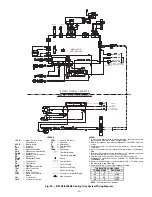

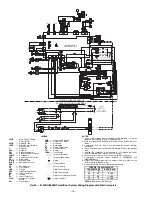

IV. Step 4 — Complete Refrigerant Piping

Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

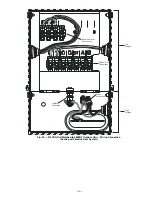

V. Step 5 — Make Electrical Connections

. . . . . . . . . 11

INSTALLATION OPTIONS

. . . . . . . . . . . . . . . . . . . . . . . .19-22

I. Fresh Air Intake

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

II. Conditioned Air Supply to Adjacent Room

. . . . . . 19

III. Room Controller Configuration Setup

. . . . . . . . . . 21

IV. Louver Mode Selection

. . . . . . . . . . . . . . . . . . . . . . 21

V. Main Board Configuration

. . . . . . . . . . . . . . . . . . . . 21

START-UP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22,23

SERVICE AND MAINTENANCE

. . . . . . . . . . . . . . . . . . . . . . 23

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23,24

SAFETY CONSIDERATIONS

Installing and servicing air-conditioning equipment can be

hazardous due to system pressure and electrical components.

Only trained and qualified service personnel should install or

service air-conditioning equipment.

Untrained personnel can perform basic maintenance, such as

cleaning and replacing filters. All other operations should be

performed by trained service personnel. When working on air

conditioning equipment, observe safety precautions in litera-

ture, tags, and labels attached to unit.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for brazing operations. Have fire extin-

guisher available. Read these instructions

thoroughly

. Con-

sult local building codes and the National Electrical Code

(NEC) for special installation requirements.

GENERAL

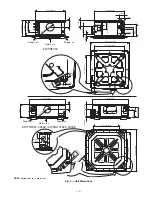

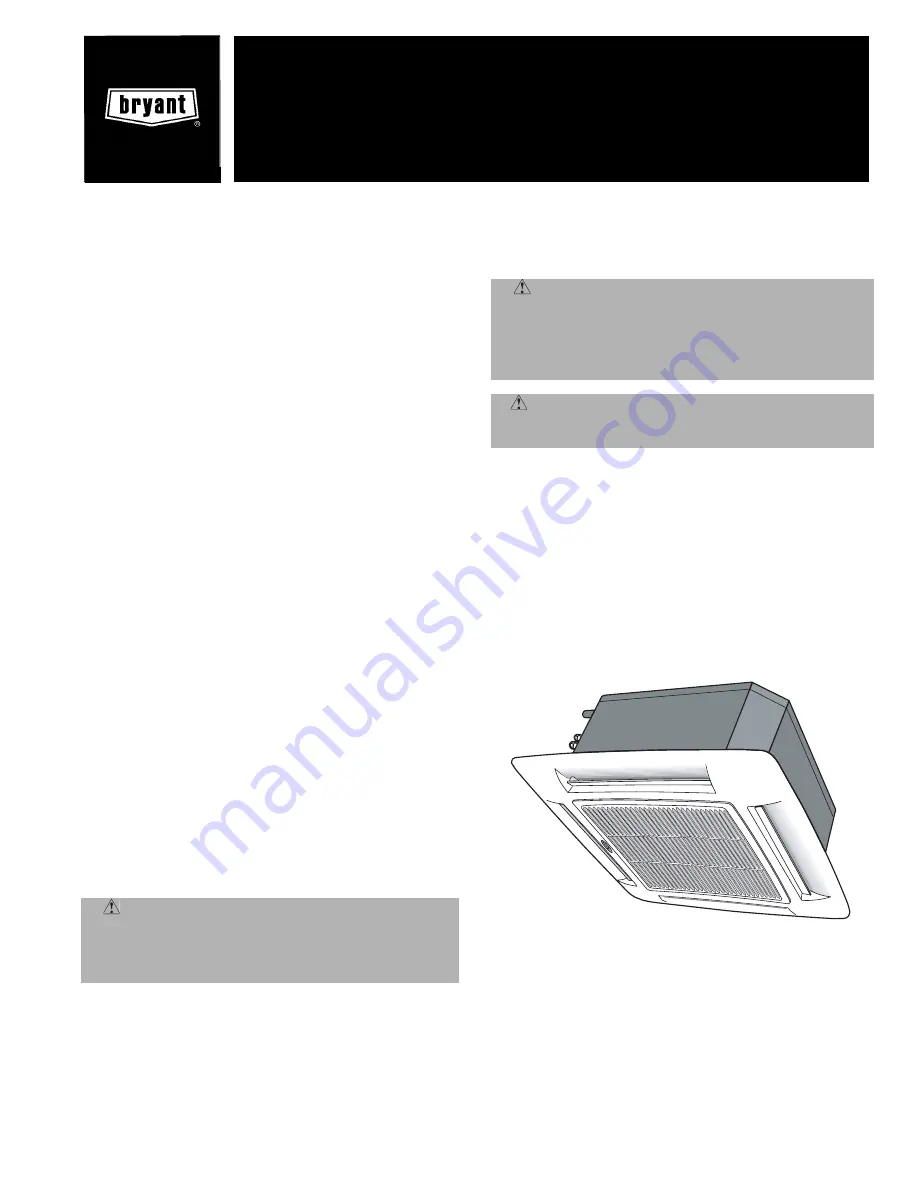

These instructions cover the installation, start-up and service

of in-ceiling cassette fan coil units. See Fig. 1.

The following accessories can be used with 619FNF, FNQ

units. See the price pages for part numbers and additional

information for the following accessories:

• photocatalytic and electrostatic filter with mount

• air supply outlet obstruction kit

• wired room controller

• room controller wiring kit for multiple units

• zone manager kit for multiple units

• zone manager

• infrared remote kit

WARNING:

Before installing or servicing system,

always turn off main power to system. There may be

more than one disconnect switch. Turn off accessory

heater power if applicable. Electrical shock can cause

serious personal injury.

CAUTION:

This system uses Puron® refrigerant

(R-410A), which has higher pressures than R-22 and

other refrigerants. No other refrigerant may be used in

this system. All equipment must be designed to handle

R-410A refrigerant. If unsure about equipment, consult

the equipment manufacturer.

CAUTION:

Do not operate the unit without a filter

or with the grille removed. Damage to the unit or per-

sonal injury may result.

Fig. 1 — 619FNF, FNQ Unit