—16—

E

T

T

E

S

S

A

C

L

A

B

O

L

G

Q

N

F

619

R

E

S

N

E

D

N

O

C

R

O

O

D

T

U

O

F

N

E

538

NOTE 6

NOTE 5

Y

A

L

P

S

I

D

R

I

A

-

M

T

L

I

O

C

-

M

T

"

D

"

R

A

L

U

D

O

M

B

C

P

1

L

O

R

T

N

O

C

R

E

P

P

O

C

E

R

A

B

T

C

E

N

N

O

C

S

I

D

T

I

N

U

O

T

)

D

E

D

I

V

O

R

P

E

L

B

A

C

E

S

U

(

D

N

G

.

P

I

U

Q

E

V

0

3

2

/

8

0

2

H

P

1

)

9

E

T

O

N

E

E

S

(

R

O

O

D

T

U

O

O

T

T

C

E

N

N

O

C

S

I

D

T

I

N

U

7

E

T

O

N

D

N

G

P

I

U

Q

E

E

T

T

E

S

S

A

C

O

T

E

T

T

E

S

S

A

C

O

T

NOTE 4

8

E

T

O

N

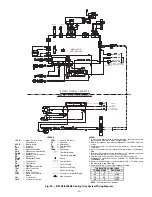

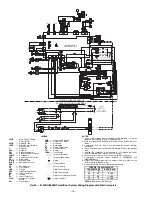

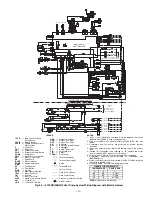

Fig. 25 — 619FNQ/538ENF Heat/Cool System Wiring Diagram with Electric Heaters

LEGEND

1PCB

—

Main Control Printed

Circuit Board

2PCB

—

Display Board

3PCB

—

Printed Circuit Board for

Electric Heat

C

—

Contactor

CAP

—

Capacitor

CH

—

Crankcase Heater

CHS

—

Crankcase Heater Switch

COMP

—

Compressor

CRC

—

Carrier Room Controller

DP

—

Drain Pump

E-HTR

—

Electric Heater

EQUIP.

GND

—

Equipment Ground

FC

—

Fan Capacitor

FS

—

Float Switch

GND.

—

Ground

HPS

—

High Pressure Switch

IFM

—

Indoor Fan Motor

IR

—

Infrared

ITP

—

Indoor Test Point

LLPS

—

Liquid Low Pressure

Switch

LM

—

Louver Motor

LMS

—

Louver Micro Switch

OFM

—

Outdoor Fan Motor

OL

—

Overload

S

—

Emergency

ST

—

Safety Thermostat

TB

—

Terminal Block

TM

—

Sensor

TRAN —

Transformer

Terminal (Marked)

Terminal (Unmarked)

Splice

Terminal Block

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

Plug Connector

NOTES:

1. If any of the original wire furnished must be replaced, it must be

replaced with Type 90° C wire or its equivalent.

2. Wire in accordance with National Electrical Code (NEC) and local

codes.

3. Compressor and fan motors are protected by internal thermal

overloads.

4. Indoor unit transformer has internal 2A thermal fuse on the primary

side.

5. Infrared (IR) connection to be inserted on “J5” (replace the actual

factory-installed “CRC” connector) for IR control.

6. Terminal strip for Carrier Room Controller (CRC) connection.

7. Compressor crankcase heater installed on 538QNF035 and

538QNF030 only.

8. Outdoor unit transformer is factory wired for 230 v. For 208 v move

the black wire to the 208-v tap.

9. Use minimum 60° C wire for the field power wiring.

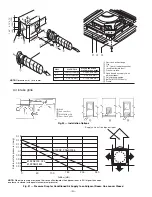

NOTE:

All thermistors are identical.

THERMISTOR EQUIVALENCE

TEMPERATURE

RESISTANCE

°F

°C

Ω

95

35

6,500

72

22

11,400

32

0

32,500