—23—

4. Ensure that the filters and return air grilles have

been installed and that the discharge louvers are

correctly positioned.

SERVICE AND MAINTENANCE

Remove unit grille, filter, and condensate pan for cleaning,

lubricating, or replacing parts.

I. MINIMUM MAINTENANCE

1. Check, clean, or replace air filter each month or as

required.

2. Check cooling coil, drain pan, condensate trap, and

condensate drain pan each cooling season for cleanli-

ness. Clean as necessary.

3. Check fan motor and wheel for cleanliness each heat-

ing and cooling season.

4. Check electrical connections for tightness and con-

trols for proper operation each heating and cooling

season. Service as necessary.

II. SERVICE

A. To Clean or Replace Air Filters

1. Place a plastic sheet on the floor to catch any water

that may spill from drain pan.

2. Slide filter out.

3. Vacuum clean or wash filter with soapy water. Rinse

and let air dry. If filter needs replacing, filters are

available from the local dealer.

B. To Clean or Replace Drain Pan

1. Place a plastic sheet on the floor to catch any water

that may spill from drain pan.

2. Remove the air intake and distribution assembly.

Remove the condensate water in the drain pan by

pulling out the rubber drain plug and letting water

drain into a 3-gallon bucket.

3. Remove screws holding the drain pan. Carefully hold

the drain pan to remove it from the assembly.

4. Reinstall the drain pan using the appropriate num-

ber of screws. Center and align the metal fan inlet

orifice with the fan. Ensure the fan spins freely.

TROUBLESHOOTING

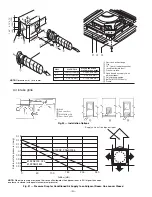

See Table 9 and Fig. 35 for troubleshooting information.

I. FAULT CODE

Once a failure occurs with the indoor unit in operation, the

green LED on the indoor unit flashes at intervals of 0.5 sec-

onds. The fault code is deduced from the number of times the

green LED flashes, blocking unit operation. Between one

flash cycle and the next one, a pause of 5 seconds elapses.

See Fig. 35.

Table 9 — Fault Codes

*When code is enabled.

A. Using the Emergency Button

The Emergency button is for use by a qualified service tech-

nician only. The Emergency button is for use when the room

controller is inoperative. Use a screwdriver to press the

emergency button through the metal protection grille. See

Fig. 35.

Emergency Operation

When the unit is in the OFF mode and the Emergency but-

ton is pressed for 5 seconds, the unit will operate as follows:

• Automatic mode

• temperature preset to 72 F

• automatic fan speed

• louvers set automatically according to the operating mode

• Timer function is cancelled

• buzzer beeps

When the unit is ON and the Emergency button is pressed

for 5 seconds, the unit will operate as follows:

• the unit is turned off

• buzzer beeps

When a signal is received by the remote control, the unit

operates accordingly.

CAUTION:

Never operate unit without a filter or

with grille removed. Damage to the unit or personal

injury may result.

CAUTION:

To avoid personal injury or damage to

unit, do not service until all power sources are shut

down, locked out, and tagged out. Failure to do so could

result in personal injury or unit damage.

CAUTION:

If air filter is not replaced in the unit,

dust and dirt gather in air conditioner and operation

becomes impaired.

CAUTION:

Do not use a screw driver to pry drain

pan out of assembly. It could damage the pan.

CODE

DESCRIPTION

2

Condensate discharge pump

3

Room air sensor fault

4

Indoor unit coil sensor fault

6*

Filter dirty

7

Outdoor unit failure

10

EEPROM corrupt

11

Card serial number damaged

12

Address or zone incomplete

13

Gas flow distributor corrupt

14

Outdoor air thermistor fault

Fig. 34 — Inserting Water into Drain Pan