800SA/801SA: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

20

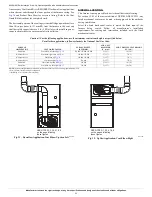

NOTES FOR THERMOSTAT WIRING DIAGRAMS

1. Heat pump MUST have a high pressure switch for HYBRID

HEAT

®

dual fuel applications.

2. Refer to outdoor equipment Installation Instructions for additional

information and setup procedure.

3. If the heat pump date code is 1501E or earlier, select the “ZONE”

position on the two speed heat pump control. Heat pumps with date

code 1601E and later do not have or require a “ZONE” selection.

4. Outdoor Air Temperature Sensor must be attached in all HYBRID

HEAT

®

dual fuel applications.

5. Configure the thermostat for air conditioner installations. Refer to

thermostat instructions.

6. Configure thermostat for heat pump installations. Refer to

thermostat instructions.

7. Configure thermostat for single-stage compressor operation. Refer

to thermostat instructions.

8. Configure thermostat for HYBRID HEAT

®

dual fuel operation.

Refer to thermostat instructions.

9. NO connection should be made to the furnace HUM terminal when

using a thermostat with a 24 volt humidifier output.

10. The RVS Sensing terminal “L” should not be connected. This is

used internally to sense defrost operation.

11. If thermostat has internal control of heat pump balance point, DO

NOT SELECT the “FURNACE INTERFACE” or “BALANCE

POINT” option on the two-speed heat pump control board. Refer to

thermostat instructions.

12. Thermostat signals may vary. Consult thermostat installation

instructions for more information.

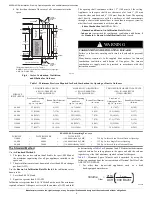

VENTING

The furnace shall be connected to a listed factory built chimney or vent,

or a clay-tile lined masonry or concrete chimney. Venting into an unlined

masonry chimney or concrete chimney is prohibited.

When an existing Category I furnace is removed or replaced, the original

venting system may no longer be sized to properly vent the attached

appliances. An improperly sized Category I venting system could cause

the formation of condensate in the furnace and vent, leakage of

condensate and combustion products, and spillage of combustion

products into the living space.

Vent system or vent connectors may need to be resized. Vent systems or

vent connectors, must be sized to approach minimum size as determined

using appropriate table found in the NFGC.

GENERAL VENTING REQUIREMENTS

Follow all safety codes for proper vent sizing and installation

requirements, including local building codes, the current edition of

National Fuel Gas Code ANSI Z223.1/NFPA 54 (NFGC), Parts 12 and

13, the local building codes, and furnace and vent manufacturers’

instructions.

These furnaces are design-certified as Category I furnaces in accordance

with current edition of ANSI Z21.47/CSA 2.3 and operate with a

non-positive vent static pressure to minimize the potential for vent gas

leakage. Category I furnaces operate with a flue loss not less than 17

percent to minimize the potential for condensation in the venting system.

These furnaces are approved for common venting and multistory venting

with other fan assisted or draft hood equipped appliances in accordance

with the NFGC, the local building codes, and furnace and vent

manufacturers’ instructions.

The following information and warning must be considered in addition

to the requirements defined in the NFGC.

1. If a vent (common or dedicated) becomes blocked, the furnace will

be shut off by the draft safeguard switch located on the vent elbow.

2. Do not vent this Category I furnace into a single-wall dedicated or

common vent. The dedicated or common vent is considered to be

the vertical portion of the vent system that terminates outdoors.

3. Vent connectors serving Category I furnaces shall not be connected

into any portion of a mechanical draft system operating under

positive pressure.

4. Do not vent this appliance with any solid fuel burning appliance.

5. Category I furnaces must be vented vertically or nearly vertically

unless equipped with a listed power venter.

6. Do not vent this appliance into an unlined masonry chimney. (Refer

).

A10133

Fig. 30 – Chimney Inspection Chart

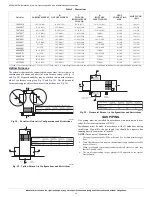

MASONRY CHIMNEY REQUIREMENTS

NOTE:

These furnaces are CSA design-certified for use in exterior

tile-lined masonry chimneys with a factory accessory Chimney Adapter

Kit. Refer to the furnace rating plate for correct kit usage. The Chimney

Adapter Kits are for use with ONLY furnaces having a Chimney Adapter

Kit numbers marked on the furnace rating plate.

If a clay tile-lined masonry chimney is being used and it is exposed to

the outdoors below the roof line, relining might be required. Chimneys

shall conform to the Standard for Chimneys, Fireplaces, Vents, and Solid

Fuel Burning Appliances current edition of ANSI/NFPA 211 and must

be in good condition.

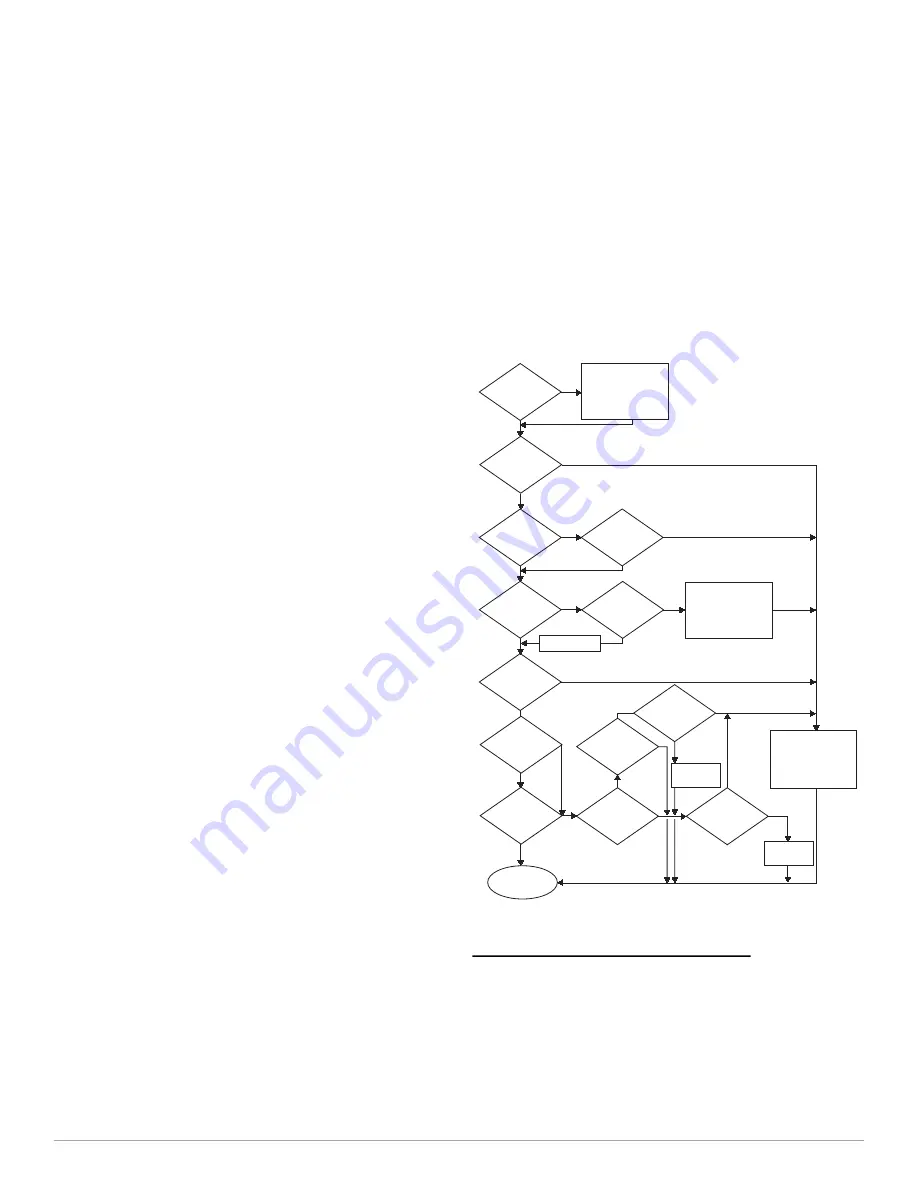

CHIMNEY INSPECTION CHART

For additional requirements refer to the National Fuel Gas Code NFPA 54/ANSI Z223.1 and ANSI/NFPA 211

Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances

Consult

Part C of

chimney adapter venting

instructions for

application

suitability

Is chimney

lined with properly

sized, listed liner or

Type-B vent?

Is chimney

to be dedicated to

a single

furnace?

Chimney

exposed to

outdoors below

roof line?

Repair

liner or top seal

or reline chimney as

necessary.

Mortar

or tile

debris?

Clay

tile misalignment,

missing sections,

gaps?

Debris

in cleanout?

Mortar, tile, metal vent,

fuel oil residue?

Is

liner and top

seal in good

condition?

Is chimney

property lined with

clay tile liner?

Crown

condition:

Missing mortar

or brick?

Rebuild

crown.

Yes

Yes

No

No

No

Reline

Yes

Repair

Yes

Yes

Yes

No

No

Remove mortar

and tile debris

Remove metal vent

or liner.

No

No

No

No

Yes

Yes

Suitable

Suitable

Not Suitable

Line chimney with property

sized, listed flexible metal

liner or Type-B vent per

NFGC Vent

Sizing Tables and liner or

vent manufacturer’s

Installation instructions.

Install chimney

adapter per

instructions.

Chimney is

acceptable for use.

Install chimney

adapter per

instructions.

Consult

Part B of

chimney adapter venting

instructions for

application

suitability.

Yes

Not Suitable

Condensate

drainage at bottom

of chimney?

Yes

No