800SA/801SA: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

7

2. For fan-assisted appliances such as this furnace:

A04003

If the following is applied to either equation:

• Iother = combined input of all other than fan-assisted appliances in

Btuh/hr

• Ifan = combined input of all fan-assisted appliances in Btuh/hr

• ACH = air changes per hour (ACH shall not exceed 0.60.)

The following requirements apply to the

Standard Method

and to the

Known Air Infiltration Rate Method

.

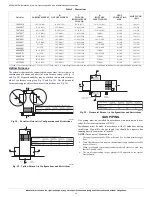

1. Adjoining rooms can be considered part of a space if:

a. There are no closeable doors between rooms.

b. Combining spaces on same floor level. Each opening shall have

free area of at least 1 in.

2

/1,000 Btuh (2,000 mm

2

/kW) of the

total input rating of all gas appliances in the space, but not less

than 100 in.

2

(0.06 m

2

). One opening shall commence within 12”

(300 mm) of the ceiling and the second opening shall commence

within 12” (300 mm) of the floor. The minimum dimension of air

openings shall be at least 3 in. (80 mm) (see

).

c. Combining space on different floor levels. The volumes of

spaces on different floor levels shall be considered as

communicating spaces if connected by one or more permanent

openings in doors or floors having free area of at least 2

in.

2

/1,000 Btuh (4,400 mm

2

/kW) of total input rating of all gas

appliances.

*Air Changes/Hour

*Minimum opening size is 100 in.2 with minimum dimensions of 3 in. (76 mm).

*Minimum of 3 in. (76 mm), when type -B1 vent is used.

A03175

Fig. 7 – Air for Combustion, Ventilation, and Dilution from Indoors

2. An attic or crawlspace may be considered a space that freely

communicates with the outdoors provided there are adequate

permanent ventilation openings directly to outdoors having free

area of at least 1-in.

2

/4,000 Btuh of total input rating for all gas

appliances in the space.

3. In spaces that use the Indoor Combustion Air Method, infiltration

should be adequate to provide air for combustion, permanent

ventilation and dilution of flue gases. However, in buildings with

unusually tight construction, additional air

MUST

be provided

using the methods described in the Outdoor Combustion Air

Method section.

4. Unusually tight construction is defined as construction with:

a.Walls and ceilings exposed to the outdoors have a continuous,

sealed vapor barrier. Openings are gasketed or sealed and

b.Doors and openable windows are weatherstripped and

c.Other openings are caulked or sealed. These include joints

around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at

penetrations for plumbing, electrical and gas lines, etc.

Combination of Indoor and Outdoor Air

1. Indoor openings shall comply with the Indoor Combustion Air

Method below and,

2. Outdoor openings shall be located as required in the Outdoor

Combustion Air Method mentioned previously and,

3. Outdoor openings shall be sized as follows:

a.Calculate the Ratio of all Indoor Space volume divided by

required volume for Indoor Combustion Air Method below.

b.Outdoor opening size reduction Factor is 1 minus the Ratio in

a. above.

c.Minimum size of Outdoor openings shall be the size required

in Outdoor Combustion Air Method above multiplied by

reduction Factor in b. above. The minimum dimension of air

openings shall be not less than 3 in. (80 mm).

Volume

Fan

= 15ft

3

ACH

I

fan

1000 Btu/hr

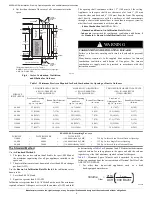

Table 2 – Minimum Space Volumes for 100% Combustion, Ventilation, and Dilution from Indoors

ACH*

OTHER THAN FAN-ASSISTED TOTAL

(1,000’S BTUH GAS INPUT RATE

FAN-ASSISTED TOTAL

(1,000’S BTUH GAS INPUT RATE)

30

40

50

44

66

88

110

132

Space Volume (ft.

3

)

0.60

1,050

1,400

1,750

1,100

1,650

2,200

2,750

3,300

0.50

1,260

1,680

2,100

1,320

1,980

2,640

3,300

3,960

0.40

1,575

2,100

2,625

1,650

2,475

3,300

4,125

4,950

0.30

2,100

2,800

3,500

2,200

3,300

4,400

5,500

6,600

0.20

3,150

4,200

5,250

3,300

4,950

6,600

8,250

9,900

0.10

6,300

8,400

10,500

6,600

9,900

13,200

16,500

19,800

0.00

NP

NP

NP

NP

NP

NP

NP

NP

CIRCULATING AIR

DUCTS

6" MIN

(FRONT)

Ü

CIRCULATING AIR DUCTS

VENT THROUGH ROOF

1 SQ IN.

PER 1000

BTUH* IN DOOR

OR WALL

12" MAX

1 SQ IN.

PER 1000

BTUH* IN DOOR

OR WALL

12" MAX

UNCONFINED

SPACE

INTERIOR

HEATED

SPACE

CLEARANCE IN FRONT OF COMBUSTION AIR

O

P

E

N

IN

G

S

S

H

A

L

L

BE A

T LEAST 3 IN.

(305mm)

(152mm)

(305mm)

![Roberts Gorden Combat UHD[S] 150-400 Specifications preview](http://thumbs.mh-extra.com/thumbs/roberts-gorden/combat-uhd-s-150-400/combat-uhd-s-150-400_specifications_1469644-1.webp)