2

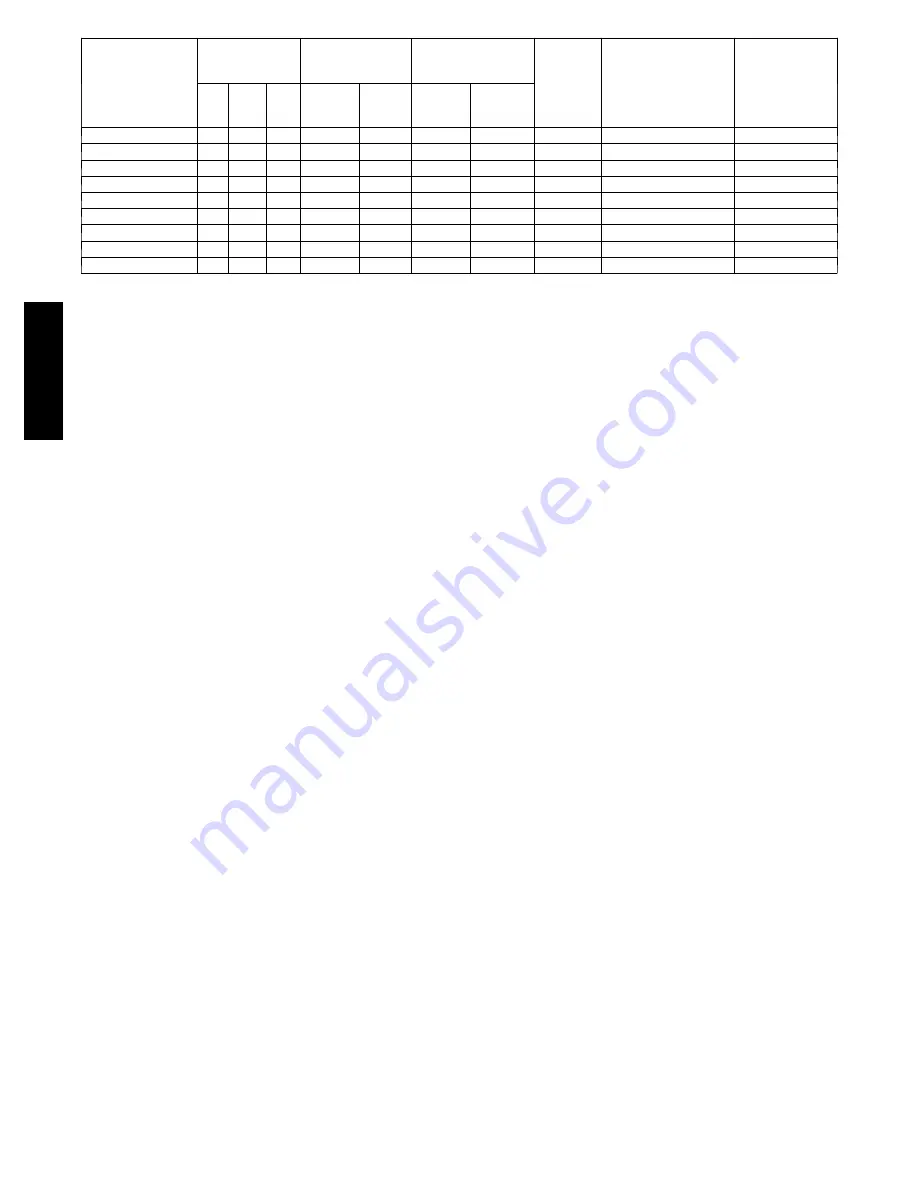

SAP ORDERING

NO.

CASING

DIMENSIONS

(IN.)

RATED HEATING

OUTPUT†

HEATING AIRFLOW COOLING

CFM

@ 0.5 ESP

(in WC)

MOTOR HP-SPEED

APPROX SHIP

WEIGHT (LB)

H

D

W

(BTUH)

AFUE

CFM‡

Heating

ESP

(in. WC)

915SA30040S14

35

29.5 14.2

39,000

95.5%

820

0.10

625-905

1/2 - 4

123

915SA30060S14

35

29.5 14.2

58,000

95.5%

840

0.12

675-1130

1/2 - 4

127

915SA42060S17

35

29.5 17.5

58,000

95.5%

980

0.12

650-1420

1/2 - 5

144

915SA48080S17

35

29.5 17.5

78,000

95.5%

1040

0.15

810-1600

3/4 - 5

154

915SA60080S21

35

29.5 21.0

78,000

95.5%

1500

0.15

1225-2025

3/4 - 5

162

915SA42100S21

35

29.5 21.0

97,000

95.5%

1565

0.20

695-1565

3/4 - 5

169

915SA60100S21

35

29.5 21.0

97,000

95.5%

1520

0.20

1225-2145

3/4 - 5

169

915SA60120S24

35

29.5 24.5 117,000

95.5%

2065

0.20

1245-2065

3/4 - 5

186

915SA60140S24

35

29.5 24.5 135,000

95.5%

2100

0.20

1230-2100

3/4 - 5

190

† Capacity in accordance with DOE test procedures. See rating plate.

‡

Heating CFM at factory default blower motor heating tap settings.

ESP --- External Static Pressure

FEATURES AND BENEFITS

HYBRID HEAT

R

Dual Fuel system

— This system can provide

more control over your monthly energy bills by automatically

selecting the most economical method of heating. With HYBRID

HEAT, our system automatically switches between the gas furnace

and the single--stage electric heat pump as outside temperatures

change to maintain greater efficiency and comfort than with any

traditional single-source heating system. The heat pump also

delivers high-efficiency cooling in the summer.

Power Heat

t

Igniter

— Bryant’s unique SiN igniter is not only

physically robust but it is also electrically robust. It is capable of

running at line voltage and does not require complex voltage

regulators as do other brands. This unique feature further enhances

the gas furnace reliability and continues Bryant’s tradition of

technology leadership and innovation in providing a reliable and

durable product.

Reliable Heat Exchanger Design

— The aluminized steel,

clamshell primary heat exchanger was reengineered to achieve

greater efficiency out of a smaller size. The first two passes of the

heat exchanger are based on the current 80% product, a design

with more than ten years of field-proven performance and success.

These innovations, paired with the continuation of a crimped,

no-weld seam create an efficient, robust design for this essential

component.

The condensing heat exchanger, a stainless steel fin and tube

design, is positioned in the furnace to extract additional heat.

Stainless steel coupling box componentry between heat exchangers

has exceptional corrosion resistance in both natural gas and

propane applications.

4-Way Multipoise Design

— One model for all applications –

there is no need to stock special downflow or horizontal models

when one unit will do it all. The new heat exchanger design allows

these units to achieve the certified AFUE in all positions.

Direct or Single-pipe Venting, or Optional Ventilated

Combustion Air

— This furnace can be installed as a 2-pipe

(Direct Vent) furnace, in an optional ventilated combustion air

application, or in single-pipe, non-direct vent applications. This

provides added flexibility to meet diverse installation needs.

Sealed Combustion System

— This furnace brings in combustion

air from outside the furnace, which results in especially quiet

operation. By sealing the entire combustion vestibule, the entire

furnace can be made quieter, not just the sound of the burners.

Monoport Burners

— The burners are specially designed and

finely tuned for smooth, quiet combustion and economical

operation.

Bottom Closure

— Factory--installed for side return; easily

removable for bottom return. The multi-use bottom closure can

also serve for roll-out protection in horizontal applications, and act

as the bottom closure for the optional return air base accessory.

Blower Access Panel Switch

— Automatically shuts off 115-v

power to furnace whenever blower access panel is opened.

Quality Registration

— Our furnaces are engineered and

manufactured under an ISO 9001 registered quality system.

Certifications

— This furnace is CSA (AGA and CGA) design

certified for use with natural and propane gases. The furnace is

factory--shipped for use with natural gas. A CSA listed gas

conversion kit is required to convert furnace for use with propane

gas. The efficiency is GAMA efficiency rating certified. This

furnace meets California Air Quality Management District

emission requirements.

915SA