13

GUIDE SPECIFICATIONS

General

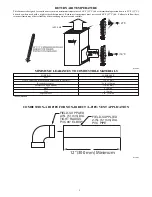

System Description

Furnish a ______________________ 4--way multipoise gas--fired

condensing furnace for use with natural gas or propane (factory--

authorized conversion kit required for propane); furnish cold air

return plenum; furnish external media cabinet for use with

accessory media filter or standard filter.

Quality Assurance

Unit will be designed, tested and constructed to the current ANSI Z

21.47/CSA 2.3 design standard for gas--fired central furnaces.

Unit will be third party certified by CSA to the current ANSI Z

21.47/CSA 2.3 design standard for gas--fired central furnaces. Unit

will carry the CSA Blue Star

R

and Blue Flame

R

labels. Unit

efficiency testing will be performed per the current DOE test

procedure as listed in the Federal Register.

Unit will be certified for capacity and efficiency and listed in the

latest AHRI Consumer’s Directory of Certified Efficiency Ratings.

Unit will carry the current Federal Trade Commission Energy

Guide efficiency label.

Delivery, Storage, and Handling

Unit will be shipped as single package only and is stored and

handled per unit manufacturer’s recommendations.

Warranty (for inclusion by specifying engineer)

U.S. and Canada only. Warranty certificate available upon request.

Equipment

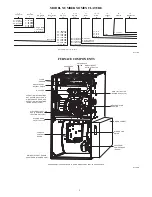

Blower Wheel and ECM Blower Motor

Galvanized blower wheel shall be centrifugal type, statically and

dynamically balanced. Blower motor of ECM type shall be

permanently lubricated with sealed ball bearings, of _______hp,

and have multiple speeds from 600--1200 RPM operating only

when 24--VAC motor inputs are provided. Blower motor shall be

direct drive and soft mounted to the blower scroll to reduce

vibration transmission.

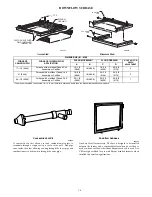

Filters

Furnace shall have reusable--type filters. Filter shall be ______ in.

(mm) X ________ in. (mm). An accessory highly efficient Media

Filter is available as an option. _____________ Media Filter.

Casing

Casing shall be of .030 in. thickness minimum, pre--painted

galvanized steel.

Draft Inducer Motor

Draft inducer motor shall be two--speed design.

Primary Heat Exchangers

Primary heat exchangers shall be 3--Pass corrosion--resistant

aluminized steel of fold--and--crimp sectional design and applied

operating under negative pressure.

Secondary Heat Exchangers

Secondary heat exchangers shall be of a stainless steel

flow--through of fin--and--tube design and applied operating under

negative pressure.

Controls

Controls shall include a micro--processor--based integrated

electronic control board with at least 16 service troubleshooting

codes displayed via diagnostic flashing LED light on the control, a

self--test feature that checks all major functions of the furnace, and

a replaceable automotive--type circuit protection fuse. Multiple

operational settings available, including blower speeds for low

heat, high heat, low cooling, high cooling and continuous fan.

Continuous fan speed may be adjusted from the thermostat.

Cooling airflow will be selectable between 325 and 400 CFM per

ton of air conditioning. Features will also include temporary

reduced

airflow

in

the

cooling

mode

for

improved

dehumidification when a T6--PRH is selected as the thermostat.

Operating Characteristics

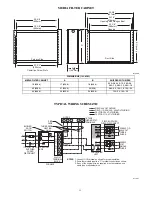

Heating capacity shall be _________________ Btuh input;

______________ Btuh output capacity.

Fuel Gas Efficiency shall be __________ AFUE.

Air delivery shall be ________________ cfm minimum at 0.50 in.

wc. external static pressure.

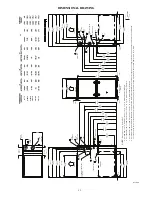

Dimensions

shall

be:

depth_________in.

(mm);

width

__________in. (mm); height___________in. (mm) (casing only).

Height shall be _________in. (mm) with A/C coil and

_________________in. (mm) overall with plenum.

Electrical Requirements

Electrical supply shall be 115 volts, 60 Hz, single--phase (nominal).

Minimum wire size shall be ________AWG; maximum fuse size

of HACR--type designated circuit breaker shall be _________

amps.

Special Features

Refer to section of the product data identifying accessories and

descriptions for specific features and available enhancements.