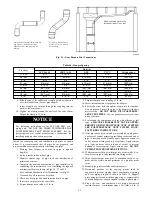

45

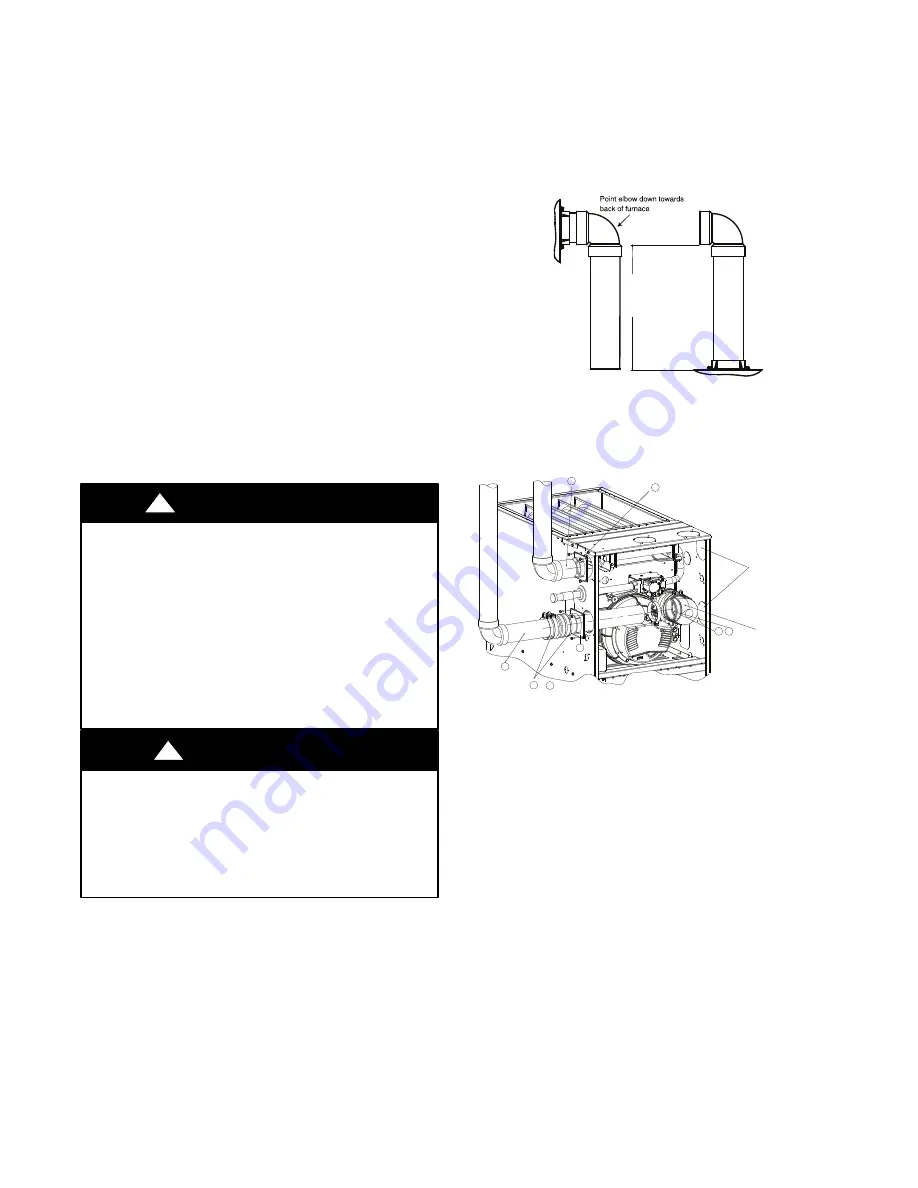

Near Furnace Vent Connections

Offsets in the vertical portion of the vent pipe should be made with

45 deg. elbows instead of 90 deg. elbows. Short horizontal runs of

vent pipe are difficult to pitch correctly and may trap water in the

vent pipe.

Trapped water in the vent pipe may result in nuisance pressure

switch tripping.

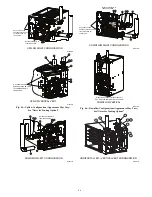

Install the Vent and Combustion Air Pipes

With the furnace installed in the required position, remove the

desired knockouts from the casing. It will be necessary to remove

one knockout for the vent pipe and the other knockout for the

combustion air connection. See Fig. 13.

Use a flat blade screwdriver and tap on the knockout on opposite

sides, where the knockout meets the casing. Fold the knockout

down with duct pliers and work the knockout back and forth until

it is removed. Trim any excess metal from the knockout with tin

snips.

The vent elbow can be rotated to the required location on the

casing if necessary. See Fig. 50. To rotate the vent elbow:

1. Loosen the clamp on the inlet of the vent elbow attached to

the inducer.

2. Rotate the vent elbow to the required position. There are

rounded notches on the vent elbow to align it with the

inducer housing for each orientation.

3. Tighten the clamp around the vent elbow. Torque the clamp

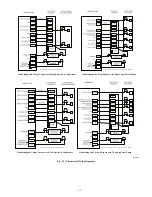

to 15 lb--in. See Fig. 45--48.

Installing the Vent Pipe Adapter and Combustion Air

Pipe Adapter

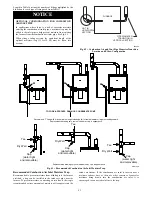

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or

death.

To route the vent pipe and combustion air pipe through the

furnace, the manufacturer supplied kit must be used. Failure to

properly seal the blower compartment from the furnace

vestibule could result in the circulation of carbon monoxide

throughout the structure. The vent pipe and combustion air pipe

must be a continuous pipe while passing through the blower

compartment. Seals supplied in this kit must be installed per the

instructions provided. Follow all procedures outlined in these

instructions.

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or death.

DO NOT

use cement to join polypropylene venting systems.

Follow the polypropylene venting system manufacturer’s

instructions for installing polypropylene venting systems.

!

WARNING

NOTE

: The rubber coupling that attaches to the vent pipe adapter

must be used. The adapter seals the vent pipe to the casing and

reduces the strain on the vent elbow attached to the inducer.

1. Apply the gaskets to the vent pipe and combustion air pipe

adapters. If supplied, remove and discard round center

“slug” from interior of gasket. See Fig. 49.

NOTE

: The vent pipe adapter can be distinguished from the inlet

pipe adapter by the absence of an internal pipe--stopping ring. The

vent pipe can pass through the vent pipe adapter; it cannot pass

through the inlet pipe adapter.

2. Align the screw holes in the plastic vent pipe adapter with

the dimples in the casing.

3. Pilot drill the screw holes for the adapter in the casing and

attach the vent pipe adapter to the furnace with sheet metal

screws

12" (256mm) minimum

to

60”(1524 mm) or

1 additional elbow maximum

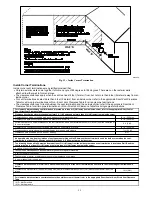

CASING SIDE OR TOP ATTACHMENT

COMBUSTION AIR PIPE

(NON-DIRECT VENT FOR ALL MODELS EXCEPT MODULATING UNLESS

INSTALLED IN ATTIC OR CRAWL SPACE)

A13406

Fig. 44 -- Combustion Air Pipe Attachment

1

2

3

4

6

7

5

5

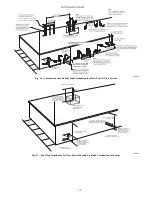

Rotate vent elbow to

required position.

Any other unused

knockout may be used

for combustion air

connection.

&

UPFLOW LEFT CONFIGURATION

A11309A