76

2. Remove control door.

3. Disconnect pressure switch tube from pressure switch port.

NOTE:

Ensure the pressure switch tube disconnected from the

pressure switch is higher than the collector box opening or water

will flow out of tube.

4. Remove the collector box plug from the top port on the up-

per corner of the collector box. See

Fig.

60.

5. Attach a funnel with a flexible tube to port on the collector

box.

6. Flush inside of collector box with water until discharge wa-

ter from condensate trap is clean and runs freely.

7. Repeat steps 4 thru 6 with bottom plug on upper corner of

collector box.

8. Remove the pressure switch tube from the collector box.

NOTE

: Do

NOT

blow into tube with tube connected to the

pressure switch.

9. Clean pressure switch port on collect box with a small wire.

Shake any water out of pressure switch tube.

10. Reconnect tube to pressure switch and pressure switch port.

11. Remove the relief tube from the port on the collector box

and the trap.

12. Clean the relief port on collect box and the trap with a small

wire. Shake any water out of the tube.

13. Reconnect relief tube to trap and collector box ports.

Cleaning Condensate Drain and Trap

NOTE

: If the condensate trap is removed, a new gasket between

the trap and collector box is required. Verify a condensate trap

gasket is included in the service kit or obtain one from your local

distributor.

1. Disconnect power at external disconnect, fuse or circuit

breaker.

2. Turn off gas at external shut-off or gas meter.

3. Remove control door and set aside.

4. Turn electric switch on gas valve to OFF.

5. Disconnect external drain from condensate drain elbow or

drain extension pipe inside the furnace and set aside.

6. Disconnect the condensate trap relief hose from collector

box port and condensate trap.

NOTE

: If condensate has a heat pad attached to the trap, trace the

wires for the pad back to the connection point and disconnect the

wires for the heat pad.

7. Remove the screw that secures the condensate trap to the

collector box, remove the trap and set aside.

8. Remove the trap gasket from the collector box if it did not

come off when the trap was removed.

9. Discard the old trap gasket.

10. Rinse condensate trap in warm water until trap is clean.

11. Flush condensate drain lines with warm water. Remember

to check and clean the relief port on the collector box.

12. Shake trap dry.

13. Clean port on collector box with a small wire.

To re-install Condensate Drain and Trap:

1. Remove adhesive backing from condensate trap gasket

2. Install gasket on collector box

3. Align the condensate trap with the drain opening on the col-

lector box and secure the trap with the screw

4. Attach the relief hose to the relief port on the condensate

trap and collector box.

5. Secure tubing to prevent any sags or traps in the tubing.

6. Connect condensate drain elbow or drain extension elbow

to the condensate trap

7. Connect the leads of the condensate heat pad (if used)

8. Connect external drain piping to the condensate drain elbow

or drain extension pipe.

9. Turn gas on at electric switch on gas valve and at external

shut-off or meter

10. Turn power on at external disconnect, fuse or circuit break-

er.

11. Run the furnace through two complete heating cycles to

check for proper operation

12. Install control door when complete.

Checking Heat Pad Operation (If Applicable)

In applications where the ambient temperature around the furnace

is 32

_

F or lower, freeze protection measures are required. If this

application is where heat tape has been applied, check to ensure it

will operate when low temperatures are present.

NOTE:

The Heat Pad, when used, should be wrapped around the

condensate drain trap. There is no need to use heat tape within the

furnace casing. Most heat tapes are temperature activated, and it is

not practical to verify the actual heating of the tape. Check the

following:

1. Check for signs of physical damage to heat tape such as

nicks, cuts, abrasions, gnawing by animals, etc.

2. Check for discolored heat tape insulation. If any damage or

discolored insulation is evident, replace heat tape.

3. Check that heat tape power supply circuit is on.

Cleaning Heat Exchangers

The following items must be performed by a qualified service

technician.

Primary Heat Exchangers

If the heat exchangers get an accumulation of light dirt or dust on

the inside, they may be cleaned by the following procedure:

NOTE:

If the heat exchangers get a heavy accumulation of soot

and carbon, both the primary and secondary heat exchangers

should be replaced rather than trying to clean them thoroughly due

to their intricate design. A build--up of soot and carbon indicates

that a problem exists which needs to be corrected, such as improper

adjustment of manifold pressure, insufficient or poor quality

combustion air, improper vent termination, incorrect size or

damaged manifold orifice(s), improper gas, or a restricted heat

exchanger (primary or secondary). Action must be taken to correct

the problem.

1. Turn off gas and electrical supplies to furnace.

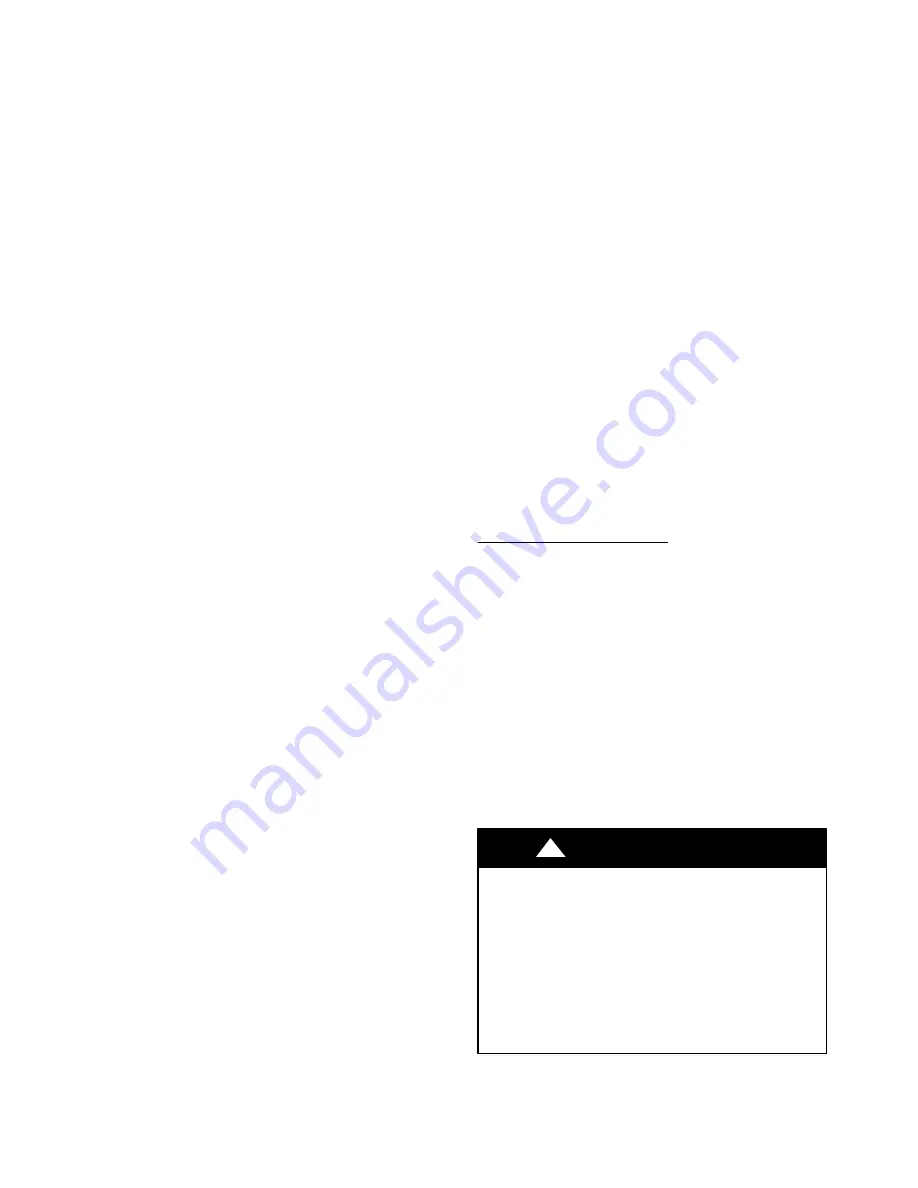

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury or death, or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position and

install a lockout tag.

There may be more than one

disconnect switch. Lock out and tag switch with a suitable

warning label. Verify proper operation after servicing.

Always reinstall access doors after completing service and

maintenance.

!

WARNING