5

S

Do not cover the furnace, store trash or debris near it, or in any

way block the

fl

ow of fresh air to the unit.

In addition to the safety rules above, make sure that the following

combustion--air requirements are met for non--direct vent

applications:

S

Combustion air must be clean and uncontaminated with chlorine

or fluorine. These compounds are present in many products

around the home, such as: water softener salts, laundry bleaches,

detergents, adhesives, paints, varnishes, paint strippers, waxes,

and plastics.

S

Make sure the combustion air for your furnace does not contain

any of these compounds. During remodeling be sure the

combustion air is fresh and uncontaminated. If these compounds

are burned in your furnace, the heat exchangers may deteriorate.

S

A furnace installed in an attic or other insulated space must be

kept free and clear of insulating material. Examine the furnace

area when the furnace is installed or when insulation is added.

Some insulation materials may be combustible.

S

Should the gas supply fail to shut off or if overheating occurs,

shut off the gas valve to the furnace before shutting off electrical

supply.

This furnace contains SAFETY DEVICES which must be

MANUALLY RESET. If the furnace is left unattended for an

extended period of time, have it checked periodically for proper

operation. This precaution will prevent problems associated with

no heat, such as frozen water pipes, etc. See “Before You Request

a Service Call” section in this manual.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, or property damage.

Do not keep combustible materials, gasoline, and other

flammable liquids or vapors around your furnace.

!

WARNING

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit

operation.

For proper and safe operation the furnace needs air for

combustion and ventilation. Do not block or obstruct air

openings on the furnace, air opening to the area in which the

furnace is installed, and the space around the furnace.

CAUTION

!

BEFORE STARTING YOUR FURNACE

Examine the furnace installation to determine that:

1. All flue gas carrying areas external to the furnace (i.e. chim-

ney, vent connector) are clear and free of obstructions.

2. The vent connector is in place, slopes upward and is physic-

ally sound without holes or excessive corrosion.

3. The return--air duct connection(s) is physically sound, is

sealed to the furnace casing, and terminates outside the

space containing the furnace.

4. The physical support of the furnace is sound without sag-

ging cracks, gaps, etc. around the base.

5. There are no obvious signs of deterioration of the furnace.

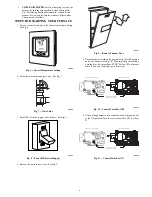

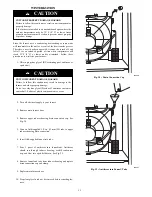

6. The burner flames are in good adjustment, See Fig. 4 (by

comparison with pictorial sketches or drawings of the main

burner flame).

A92330

Fig. 4 -- Burner Flame Adjustment

STARTING YOUR FURNACE

Instead of a continuously burning pilot flame which wastes

valuable energy, your furnace uses an automatic, hot surface

ignition system to light the burners each time the thermostat signals

the furnace to start.

Follow these important safeguards:

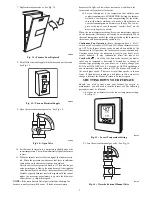

S

Never attempt to manually light the burners with a match

or other source of flame. See Fig. 5.

A92319

Fig. 5 -- Do Not Light Burner with Match

S

Read and follow the operating instructions on inside of

main furnace door, especially the item that reads as fol-

lows:

“Wait 5 minutes to clear out any gas. Then smell for gas,

including near the floor. If you smell gas,

STOP!

Fol-

low “B” in the safety information on furnace label. If you

don’t smell gas, go to the next step.”

S

If a suspected malfunction occurs with your gas control

system, such as the burners do not light when they

should, refer to the shutdown procedures on inside of

main furnace door, or in the “Shutting Down Your Fur-

nace” section and call your dealer as soon as possible.

FIRE AND EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Should the gas supply fail to shut off or if overheating occurs,

turn off the manual gas valve to the furnace BEFORE turning

off the electrical supply and install lockout tag.

!

WARNING