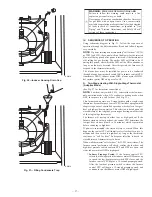

6. Switching From Low- To High- Heat- If the furnace

control CPU switches from low-heat to high-heat, the

furnace control CPU will switch the inducer motor IDM

speed from low to high. The high-heat pressure switch relay

HPSR is de-energized to close the NC contact. When

sufficient pressure is available the high-heat pressure switch

HPS closes, and the high-heat gas valve solenoid GV-HI is

energized. The blower motor BLWM will switch to HI

HEAT speed five seconds after the furnace control CPU

switches from low-heat to high-heat.

7. Switching From High- To Low- Heat-The control CPU

will not switch from high-heat to low-heat while the

thermostat R-to-W circuit is closed when a single-stage

thermostat is used.

8. Blower-Off delay- When the thermostat is satisfied, the R

to W circuit is opened, de-energizing the gas valve GV-M,

stopping gas flow to the burners, and de-energizing the

humidifier terminal HUM. The inducer motor IDM will

remain energized for a 15-second post-purge period. The

blower motor BLWM and air cleaner terminal EAC-1 will

remain energized for 90, 120, 150, or 180 seconds (depend-

ing on selection at blower-OFF delay switches). The fur-

nace control CPU is factory-set for a 120-second blower-

OFF delay.

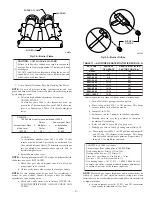

B.

Two-Stage Heating With Two-Stage Thermostat

(Non-Adaptive Heating Mode)

(See Fig. 28 and 52A-G for thermostat connections).

NOTE:

In this mode, the low-heat only switch must be ON to

select the low-heat only operation mode in response to closing the

thermostat R-to-W1 circuit. Closing the thermostat R-to-W1-

and-W2 circuits always causes high-heat operation, regardless of

the setting of the low-heat-only switch.

The wall thermostat

″

calls for heat

″

, closing the R to W1 circuit for

low-heat or closing the R to W1 and-W2 circuits for high-heat. The

furnace control performs a self-check, verifies the low-heat and

high-heat pressure switch contacts LPS and HPS are open, and

starts the inducer motor IDM in high-speed.

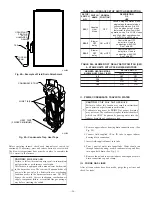

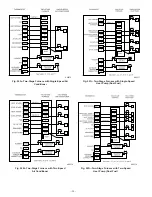

TABLE 10—MODEL 352MAV ORIFICE SIZE AND HIGH/LOW-HEAT MANIFOLD PRESSURE FOR CORRECT INPUT (CONT.)

FOR USE WITH 060 THROUGH 120 SIZE FURNACES ONLY

(TABULATED DATA BASED ON 20,000/13,000 BTUH PER BURNER, DERATED 2 PERCENT FOR EACH 1000 FT ABOVE SEA

LEVEL)*

ALTITUDE

RANGE

(FT)

AVG GAS

HEAT VALUE

(BTU/CU FT)

SPECIFIC GRAVITY OF NATURAL GAS

0.58

0.60

0.62

0.64

0.66

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

U.S.A.

Only

7001

to

8000

15%

derate

625

43

3.8/1.6

42

3.3/1.4

42

3.4/1.4

42

3.5/1.5

42

3.6/1.5

650

43

3.5/1.5

43

3.7/1.6

43

3.8/1.6

42

3.2/1.4

42

3.3/1.4

675

44

3.8/1.6

43

3.4/1.4

43

3.5/1.5

43

3.6/1.5

43

3.7/1.6

700

44

3.5/1.5

44

3.6/1.5

44

3.8/1.6

43

3.4/1.4

43

3.5/1.5

725

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

44

3.6/1.5

44

3.7/1.6

750

45

3.7/1.6

45

3.8/1.6

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

775

45

3.5/1.5

45

3.6/1.5

45

3.7/1.6

45

3.8/1.6

44

3.3/1.4

800

45

3.3/1.4

45

3.4/1.4

45

3.5/1.5

45

3.6/1.5

45

3.7/1.6

825

47

3.6/1.5

45

3.2/1.3

45

3.3/1.4

45

3.4/1.4

45

3.5/1.5

850

47

3.4/1.4

47

3.5/1.5

47

3.7/1.5

45

3.2/1.3

45

3.3/1.4

ALTITUDE

RANGE

(FT)

AVG GAS

HEAT VALUE

(BTU/CU FT)

SPECIFIC GRAVITY OF NATURAL GAS

0.58

0.60

0.62

0.64

0.66

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

U.S.A.

Only

Altitudes

8001

to

9000

17%

derate

600

43

3.8/1.6

42

3.3/1.4

42

3.4/1.4

42

3.5/1.5

42

3.6/1.5

625

43

3.5/1.5

43

3.6/1.5

43

3.8/1.6

42

3.2/1.4

42

3.3/1.4

650

44

3.7/1.6

43

3.4/1.4

43

3.5/1.5

43

3.6/1.5

43

3.7/1.6

675

44

3.5/1.5

44

3.6/1.5

44

3.7/1.6

44

3.8/1.6

43

3.4/1.5

700

44

3.2/1.4

44

3.3/1.4

44

3.4/1.5

44

3.6/1.5

44

3.7/1.6

725

45

3.6/1.5

45

3.8/1.6

44

3.2/1.4

44

3.3/1.4

44

3.4/1.4

750

45

3.4/1.4

45

3.5/1.5

45

3.6/1.5

45

3.8/1.6

44

3.2/1.4

775

45

3.2/1.3

45

3.3/1.4

45

3.4/1.4

45

3.5/1.5

45

3.6/1.5

800

47

3.6/1.5

47

3.7/1.6

45

3.2/1.3

45

3.3/1.4

45

3.4/1.4

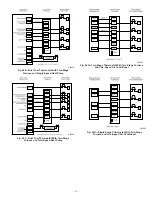

ALTITUDE

RANGE

(FT)

AVG GAS

HEAT VALUE

(BTU/CU FT)

SPECIFIC GRAVITY OF NATURAL GAS

0.58

0.60

0.62

0.64

0.66

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

Orifice

no.

Manifold

Pressure

U.S.A.

Only

9001

to

10,000

19%

derate

575

43

3.8/1.6

42

3.2/1.4

42

3.3/1.4

42

3.3/1.5

42

3.6/1.5

600

43

3.5/1.5

43

3.6/1.5

43

3.7/1.6

42

3.2/1.3

42

3.3/1.4

625

44

3.7/1.6

44

3.8/1.6

43

3.5/1.5

43

3.6/1.5

43

3.7/1.6

650

44

3.4/1.4

44

3.5/1.5

44

3.7/1.5

44

3.8/1.6

43

3.4/1.4

675

44

3.8/1.6

44

3.3/1.4

44

3.4/1.4

44

3.5/1.5

44

3.6/1.5

700

45

3.6/1.5

45

3.7/1.6

45

3.8/1.6

44

3.3/1.4

44

3.4/1.4

725

45

3.3/1.4

45

3.4/1.5

45

3.6/1.5

45

3.7/1.6

45

3.8/1.6

750

47

3.7/1.6

45

3.2/1.4

45

3.3/1.4

45

3.4/1.5

45

3.5/1.5

775

47

3.5/1.5

47

3.6/1.5

47

3.7/1.6

45

3.2/1.4

45

3.3/1.4

*Orifice numbers shown in shading are factory installed.

NOTE: Percents of derate are based on midpoint of U.S. altitude ranges.

—43—

Summary of Contents for CONDENSING GAS FURNACE 352MAV

Page 51: ...51...