3

A07617

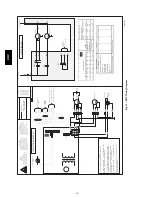

Fig. 5 -- Exhaust Ventilation

FLEXIBLE

DUCT

FRESH-AIR

SUPPLY

STALE-AIR

RETURN

DUCTS CONNECTING TO

RETURN-AIR DUCT SYSTEM

A07610

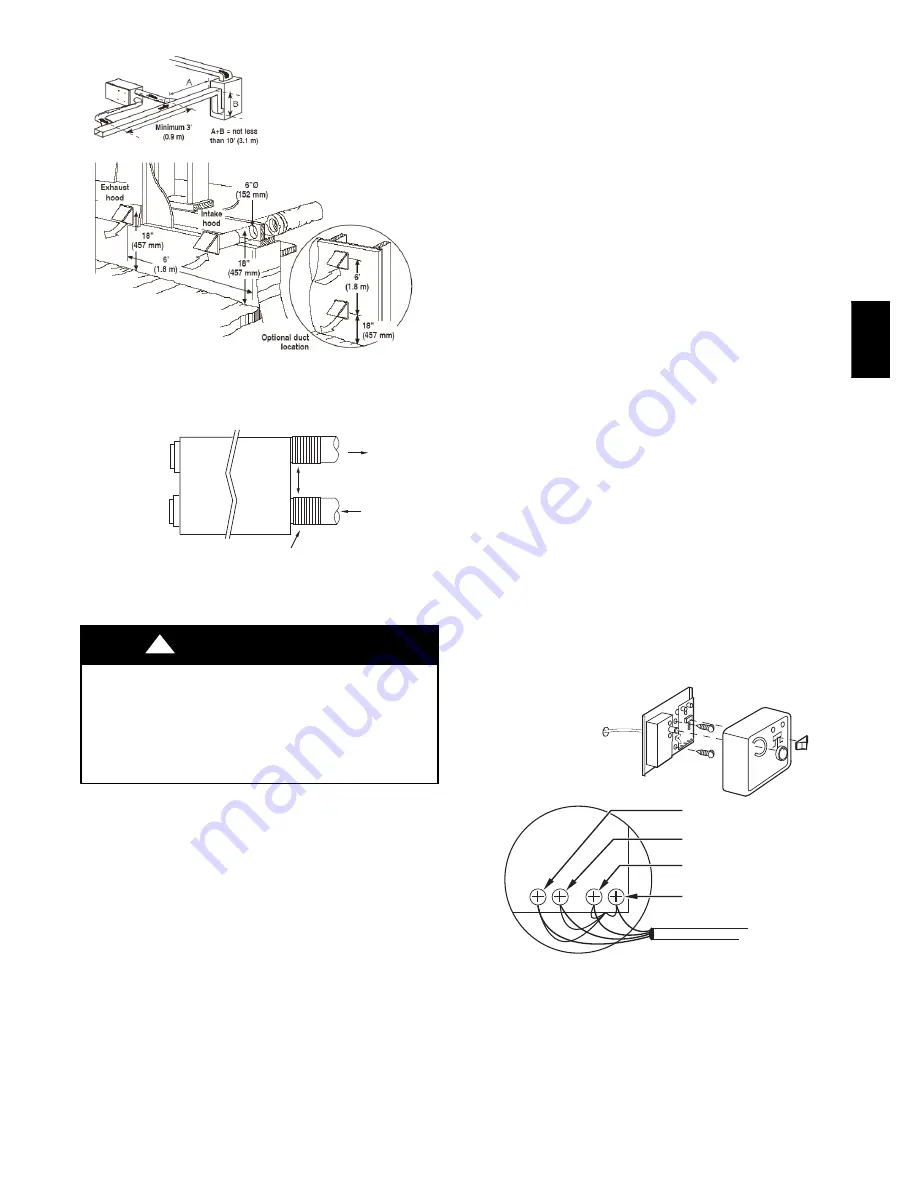

Fig. 6 -- Flexible Duct Fit--Up

Connect Ducts to ERV

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in minor property

damage from sweating duct or loss of unit efficiency and

capacity.

ERV should be installed in a conditioned space with insulated

flex duct for supply and exhaust air to the outdoor ambient.

CAUTION

!

Insulated flexible duct is required on both fresh--air inlet and

exhaust--air outlet ducts connecting to exterior wall.

When

using insulated flexible duct, the vapor barrier of the flexible ducts

must be taped very tightly to prevent condensation problems. To

reduce pressure drop, stretch the flex duct and support it in a proper

manner to avoid reduced airflow.

When connecting the ERV to a return--air duct system, insulated

flexible duct can be used. When using metal duct from fresh--air

supply to system duct work, the metal duct should be insulated (see

Fig. 6). However, when metal or rigid ducts are applied use

approximately 18” (457 mm) of flexible duct at ERV ports for

fresh--air supply and stale--air return. This can act as a silencer

when connecting ducts to return--air duct system. This should

eliminate transmission of noise or vibration from unit to main duct

system. In addition, there are four 30” (762 mm) duct ties provided

to help fasten flexible duct to port on ERV.

Locate and Install Exterior Hoods

IMPORTANT

: To prevent condensation problems, insulated

flexible ducts are required on both fresh--air inlet and exhaust--air

outlet ducts connecting between ERV and exterior wall.

Fresh--air intake and stale--air exhaust must be separated by at least

6 ft (1.8 m). Fresh--air intake must be positioned at least 10 ft (3 m)

from nearest dryer vent, furnace exhaust, driveway, gas meter, or

oil fill pipe. Fresh--air intake must be positioned as far as possible

from garbage containers and potential chemical fumes. When

possible, it is advised to locate the intake and exhaust hoods on

same side of house or building. The intake and exhaust hoods

should never be located on interior corners or in dead air pockets

(see Fig. 5). Both intake and exhaust hoods must be 18” (457 mm)

from ground and at least 12” (305 mm) above anticipated snow

level.

After selecting proper hood locations, make appropriate size hole

through exterior wall, pass flexible duct through hole and insert

hood tube into duct. Tape duct vapor barrier tightly around hood

tube and insert assembly back into wall and fasten securely.

WALL CONTROL

Location

The ERV wall control is unique to this unit. The ERV will not

operate without it. This control senses humidity not temperature. It

must be located in an area where it will continually monitor fresh

air circulating within the home. Install ERV wall control as close as

possible to main system thermostat and follow same guidelines as

installing a thermostat (locate approximately 5 ft (1.5 m) above

floor, mount on an inside partitioning wall, etc.).

Wiring

Remove top cover assembly from wall control and pass thermostat

wire through hole located on back of control before attaching to

wall. Connect Y, R, G, and B (yellow, red, green, and black)

between wall control and ERV connector following color code (see

Fig. 7 and 8). Replace top cover assembly.

NOTE

: ERV wall control and circuit board operate on 12 VDC.

YELLOW

Y

R

GB

RED

GREEN

BLACK

A00112

Fig. 7 -- Typical Wall Control

ER

V