5

DEHUM -- will only turn on if humidity is 3% over setpoint.

The speed is determined by indoor humidity and outdoor

temperature.

Cooling:

AUTO -- the ventilator selects the speed based on indoor

humidity and outdoor temperature. It may cycle on/off every

30 minutes depending on humidity and outside temperature.

LOW -- low speed all of the time.

HIGH -- high speed all of the time.

If the fan speed is set to Auto and the ventilator wants to run, the

fan speed will run at High continuous speed. Otherwise, the fan

will stay at the chosen continuous fan speed.

ELECTRICAL CONNECTIONS

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing system, always turn off main

power to system. There may be more than 1 disconnect

switch.

!

WARNING

115 VAC Wiring

The ERV operates on 115 VAC. It comes with a power cord

attached to unit and ready to plug into a fused outlet. Unit must be

grounded for proper operation.

All electrical connections must comply with National and Local

Electrical Codes, or other ordinances that might apply.

12 VDC Wiring

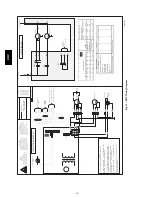

The ERV circuit board, wall control, and accessories operate on 12

VDC. See Wall Control section, item Wiring and Fig. 7 and 8 for

more information.

The ERV comes with an integrated interlock. The interlock can be

wired to the system blower to ensure that the blower is running

when there is a call for ventilation. See the wiring diagram for

proper wiring of the interlock circuit.

ACCESSORIES

20 Minute Timer

A push button timer can be used to override the wall control and

put the ERV into high speed for 20 minutes. Connect switches in

parallel and connect leads to ERV terminals I, OC, and OL (see

Fig. 9). Push button locations are ideal in special activity areas,

such as bathrooms or kitchens, where high--speed exhaust

operation is needed for a short period of time.

NOTE

: The 20 minute timer will not function properly unless

ERV wall control is applied and working correctly. Timing

function is internal to electronic circuit board, it is activated by a

momentary contact between OC and OL. The I connection is to

illuminate the push button. The maximum number of push button

timers that can be applied is 5.

60 Minute Adjustable Timer

A 60 minute adjustable timer can also be used to override wall

control and put ERV into high--speed operation for a select amount

of time. Connect timer in parallel with push button timers, or to

ERV terminals OC and OL (see Fig. 9).

BALANCING ERV

Balancing intake and exhaust airflow is very important for proper

system operation and optimum performance when applying an

ERV. Unit balancing prevents a positive and/or negative pressure

within the home. Balancing the ERV is done by using balancing

dampers in the fresh air intake and stale air exhaust ducts.

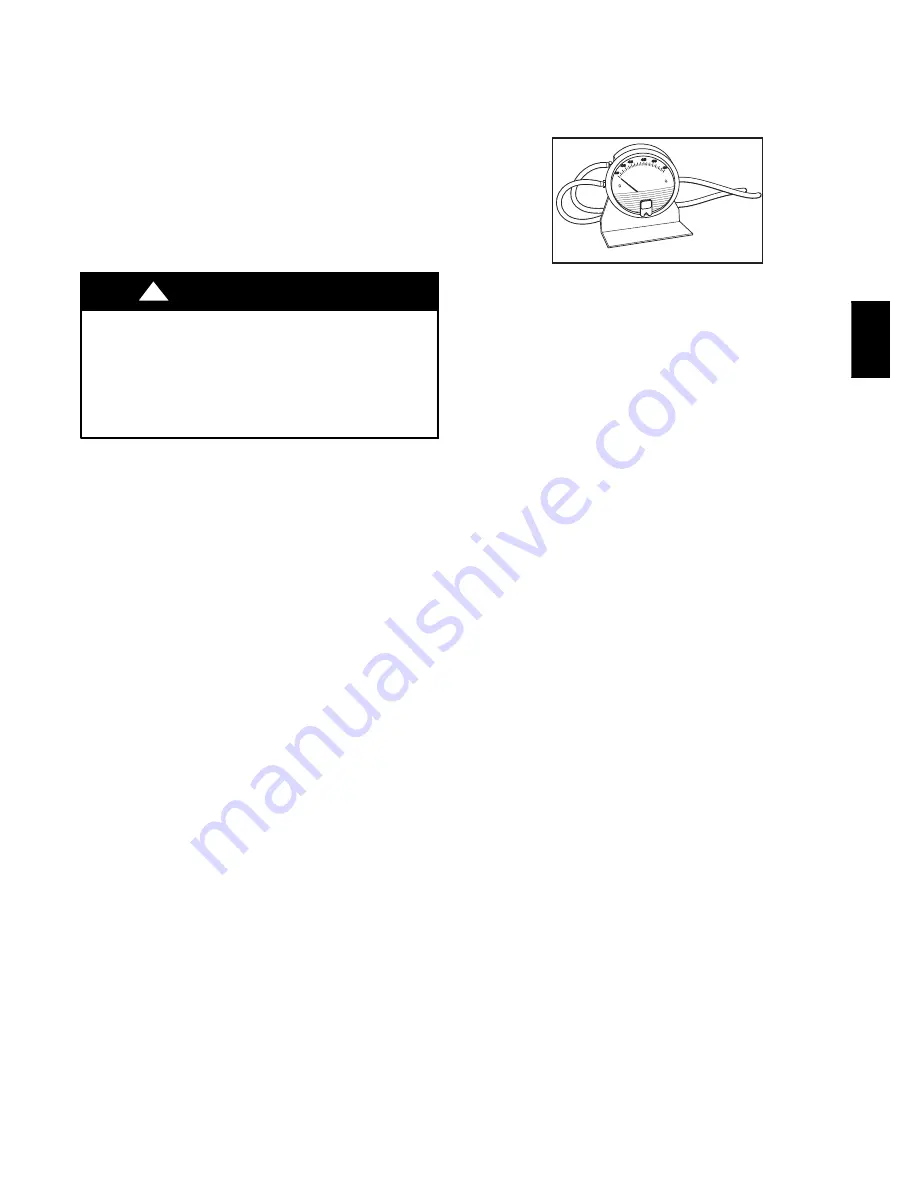

Airflow is determined by temporarily connecting a magnehelic

gauge to the pressure taps on ERV. (See Fig. 10.) Balancing chart is

located on unit door.

A98400

Fig. 10 -- Magnehelic Gauge

If supply--air from outside is greater than exhaust--air from the

house, an imbalance can result over pressurizing the home. If

exhaust--air is greater than supply--air, combustion appliances may

backdraft, bringing exhaust fumes into the house. A balanced

condition will ensure optimum performance, provide satisfied

customers, and avoid expensive callbacks.

Before proceeding with balancing, all windows, doors, and

fireplace flues should be tightly closed. No exhaust systems such as

range top exhausts, dryer exhaust, fume hoods, bath or roof fans

should be in operation. The forced--air furnace (if used for

circulation) should be operating in continuous fan mode for normal

operating speed.

Balancing Procedure

Step 1 — Set the unit to high speed.

Make sure that the furnace/air handler blower is ON if the

installation is in any way connected to the ductwork of the cold air

return. If not, leave furnace/air handler blower OFF. If the outside

temperature is below 32

_

F (0

_

C), make sure the unit is not running

in defrost while balancing. (By waiting 10 minutes after plugging

the unit in, you are assured that the unit is not in a defrost cycle.)

Step 2 — Magnehelic gauge placement.

Place the magnehelic gauge on a level surface and adjust it to zero.

Step 3 — Connect tubing from gauge to EXHAUST air

flow pressure taps.

Be sure to connect the tubes to their appropriate high/low fittings.

(See Fig. 11.) If the gauge drops below zero, reverse the tubing

connections.

NOTE

: It is suggested to start with the exhaust air flow reading

because the exhaust has typically more restriction than the fresh air,

especially in cases of fully ducted installations or source point

ventilation. Place the magnehelic gauge upright and level. Record

equivalent AIR FLOW of the reading according to the balancing

chart.

Step 4 — Move tubing to FRESH air flow pressure

taps.

Adjust the fresh air balancing damper until the fresh air flow is

approximately the same as the EXHAUST air flow. If fresh air

flow is less than exhaust air flow, then go back and adjust the

exhaust balancing damper to equal the fresh air flow. (See Fig. 11.)

Step 5 — Secure both dampers thumb screw in place

with tape.

Step 6 — Record air flow information.

Write the required air flow information on a label and stick it near

the unit for future reference (date, maximum speed air flows, your

name, phone number and business address).

ER

V