6

NOTE

:

The unit is considered balanced even if there is a

difference of

±

10 CFM (or

±

5 l/s or 17 m

3

/h) between the two air

flows.

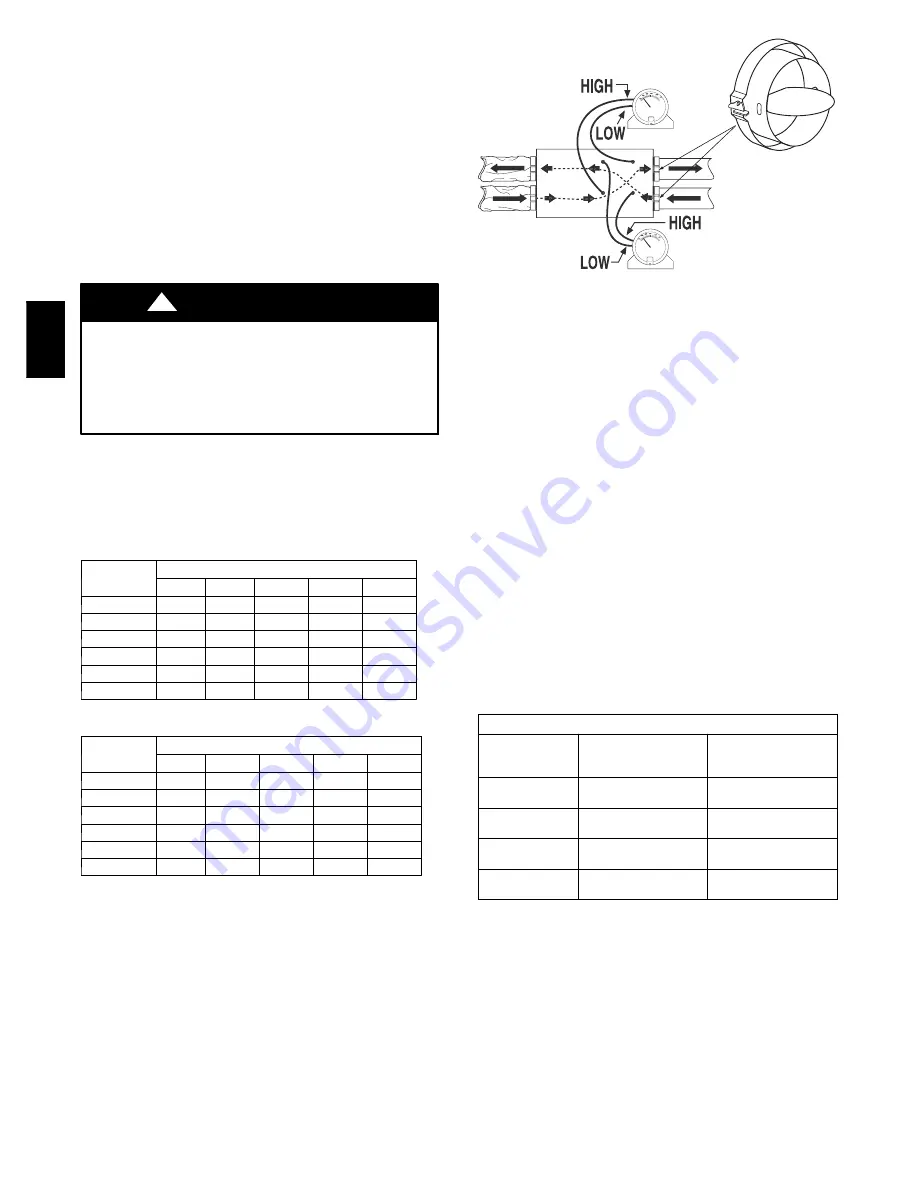

Balancing Dampers

Balancing dampers (sometimes called butterfly dampers) are

located in fresh--air intake and stale--air exhaust of the ERV. (See

Fig. 11.) Some field modification may be required to ensure proper

adjustment of balancing dampers while located in flexible duct.

Insulating over these dampers is strongly recommended after

balancing is complete to prevent condensation problems.

NOTE

: Temporary flow collars are not needed with the new

ERVBBHA models since the air flow pressure taps are

incorporated in the access door. (See Fig. 11.)

VENTILATION EVALUATION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in reduced unit

efficiency, capacity or unit life.

DO NOT use ERV during construction of a house or when

sanding drywall. This type of dust may damage system.

CAUTION

!

Ventilator Sizing

Tables 3 and 4 should be used to determine the required airflow for

a home. These guidelines are taken from ANSI/ASHRAE

62.2--2007.

Table 3 – Ventilation Air Requirements, cfm

FLOOR

AREA (ft

2

)

BEDROOMS

0---1

2---3

4---5

6---7

>7

<1500

30

45

60

75

90

1501---3000

45

60

75

90

105

3001---4500

60

75

90

105

120

4501---6000

75

90

105

120

135

6001---7500

90

105

120

135

150

>7500

105

120

135

150

165

Table 4 – Ventilation Air Requirements, L/s

FLOOR

AREA (m

2

)

BEDROOMS

0---1

2---3

4---5

6---7

>7

<139

14

21

28

35

42

139.1---279

21

28

35

42

50

279.1---418

28

35

42

50

57

418.1---557

35

42

50

57

64

557.1---697

42

50

57

64

71

>697

50

57

64

71

78

Fresh air flow

Exhaust Air Flow

A05264

Fig. 11 -- Balancing ERVBBHA

CONTROL BOARD OPERATION

Board Function

To ensure proper operation of ERV, configuration jumpers are

located on electronic control board and must match configuration

setup shown in Fig. 12 under Jumper Table. Jumpers are factory set

and do not require any changes unless control board is replaced. If

control board is replaced, or unusual start--up operation is

encountered, check jumpers to make sure they are located properly.

NOTE

: Power disconnect for 30 seconds is required to reset the

CPU when changing jumpers.

Outdoor Ambient Below 23

_

F (--5

_

C)

The ERV continually monitors outside air temperature. If outside

air is at or below 23

_

F (--5

_

C), ERV will cycle between air

exchange and defrost.

The ERV measure the incoming air temperature and will cycle unit

in and out of defrost, depending on outdoor ambient. The intake

damper will close and circulate indoor air through the core for 6 to

10 minutes. This time depends on jumper location. Refer to Table 5

for defrost cycle.

Table 5 – Defrost Cycle

ERV DEFROST CYCLES

Outside

Temp

°

F /

°

C

Standard

Defrost (as shipped)

Extended Defrost

(Jumper JU1---F

Removed)

Above 23

°

F /

---5

°

C

No Defrost

No Defrost

23 to 5

°

F /

---5 to ---15

°

C

10 Minute Defrost/60

Minute Exchange

10 Minute Defrost/30

Minute Exchange

4 to ---17

°

F /

---16 to ---27

°

C

10 Minute Defrost/30

Minute Exchange

10 Minute Defrost/20

Minute Exchange

Below ---18

°

F /

---28

°

C

10 Minute Defrost/20

Minute Exchange

10 Minute Defrost/15

Minute Exchange

OFF and INTERMITTENT/OFF Mode

When ERV is Off, K1 relay is open (see Fig. 12).

High--Speed Air Exchange

When high--speed air exchange occurs, K1 relay closes and K2 (12

VDC relay) is energized. This opens low--speed contacts, and

closes high--speed contacts. Then, 115 VAC is applied between

orange and gray wires on Molex

R

plug (pins 1 and 6) and blower

motor runs in high--speed operation. Also, 115 VAC is applied

across pins 5 and 7, this energizes interlock relay (see Fig. 12).

Low--Speed Air Exchange

When low--speed air exchange occurs, K1 relay closes and K2 (12

VDC relay) is de--energized. This keeps low--speed contacts closed

and high--speed contacts open. Then, 115 VAC is applied between

ER

V