(9.) Clean burner assembly using vacuum cleaner with soft brush attachment.

(10.) Reinstall cell inlet plates and burner assembly. Care must be exercised to center the burners in the cell openings.

9. After cleaning flue openings, check sealant on flue collector to ensure that it has not been damaged. If new sealant is needed, contact your

dealer or distributor.

10. Clean and replace flue collector assembly, making sure all 8 screws are secure.

11. Reinstall relief box.

12. Reconnect wires to the following components.

a. Draft safeguard switch

b. Inducer motor

c. Pressure switch

d. Limit overtemperature switch(es)

e. Gas valve

f. Hot surface ignitor

g. Flame-sensing electrode

13. Reconnect vent pipe to relief box. Replace vent pipe enclosure (downflow/horizontal furnace only).

14. Replace blower access door only.

15. Turn on electrical power and gas.

16. Set thermostat and check furnace for proper operation.

WARNING: Never use a match or other open flame to check for gas leaks. Use a soap-and-water solution. A failure to

follow this warning could result in fire, personal injury, or death.

17. Check for gas leaks.

18. Replace control access door on upflow furnace.

19. On downflow/horizontal furnaces, remove blower access door, replace control access door first, then replace blower access door and secure

with screw in front of door.

D.

Electrical Controls and Wiring

CAUTION: There may be more than 1 electrical supply to the unit. Check accessories and cooling unit for additional

electrical supplies.

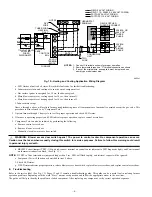

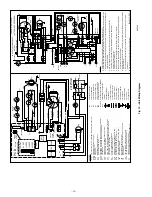

The electrical ground and polarity for 115-v wiring must be maintained properly. Refer to Fig. 10 for field wiring information and to Fig. 12 for

unit wiring information.

NOTE:

If the polarity is not correct, the STATUS LED on the control center will flash rapidly and prevent the furnace from operating. The control

system also requires an earth ground for proper operation of the control board and flame-sensing electrode.

The 24-v circuit contains an automotive-type, 3-amp fuse located on the control board. (See Fig. 11.) Any direct shorts of the 24-v wiring during

installation, service, or maintenance will cause this fuse to blow. If fuse replacement is required, use ONLY a fuse of identical size.

With power to the unit disconnected, check all electrical connections for tightness. Tighten all screws on electrical connections. If any smoky or

burned connections are found, disassemble the connection, clean all parts, strip wire, and reassemble properly and securely.

Reconnect electrical power to the unit and observe unit through 1 complete operating cycle. Electrical controls are difficult to check without proper

instrumentation; if there are any discrepancies in the operating cycle, contact your dealer and request service.

For an explanation of fault codes, refer to service label located on blower access door or Fig. 13, and the troubleshooting guide.

The control center stores 1 fault code (the last fault to occur) for a period of 48 hr or until the 115- or 24-v power is interrupted.

NOTE:

Removing blower access door will open blower access door switch and terminate 115-v power to control center, and fault code will be

erased. Look into blower access door sight glass for current LED status.

1. To retrieve fault code, proceed with the following:

NOTE:

NO thermostat signal may be present at control center, and all blower time delay off periods must be completed.

a. Leave 115-v power to furnace turned on.

b. Look into blower access door sight glass for current LED status.

NOTE:

Leave blower access panel installed to maintain power to control center to view current LED status.

c. Remove control access door.

d. BRIEFLY remove either wire from the main limit switch until LED goes out, then reconnect it.

NOTE:

If wire to main limit is disconnected longer than 4 sec, main blower starts, and retrieval request is ignored.

2. When above items have been completed, the following will occur:

—7—

Summary of Contents for GB1AAV

Page 15: ...15...