NOTE:

Read the entire instruction in manual applicable to

specific unit before starting the installation. This symbol

→

indicates a change since the last issue.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause personal injury or property damage.

Consult a qualified installer, service agency, distributor, or branch

for information or assistance. The qualified installer or agency

must use factory-authorized kits or accessories when modifying

this product. Refer to the individual instructions packaged with the

kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special require-

ments.

Recognize safety information. This is the safety-alert symbol

.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

WARNING:

Before installing or servicing system, al-

ways turn off main power to system. There may be more

than 1 disconnect switch. Turn off accessory heater

power if applicable. Electrical shock can cause personal

injury or death.

CAUTION:

Unit must not be installed where freezing

temperatures could occur. Do not install unit on the

furnace or fan coil jacket. Do not install unit where ends

of cooling coil could restrict airflow to the humidifier.

Condensation damage could occur if home has closed-

off, unheated rooms.

INSTALLATION OF HUMBBLBP2018-A--

BYPASS HUMIDIFIER

Bryant’s HUMBBLBP2018-A-- bypass humidifier can be installed

on either the supply or return plenum of a forced-air system. This

unit requires an external bypass duct between the supply- and

return-air ductwork.

It is recommended to install the humidifier where it can be easily

serviced. If this humidifier is installed with a central cooling

system the bypass duct must have a shutoff damper to close during

the cooling season. Always install humidifier downstream of an

electronic air cleaner.

→

Humidifiers

A98361

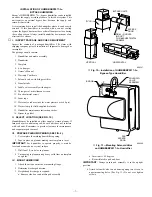

MODEL HUMBBLFP1025-A--

FAN-POWERED

HUMIDIFIER

MODEL HUMBBSFP1016-A--

FAN-POWERED

HUMIDIFIER

MODEL HUMBBWTR2019-A--

WATER-SAVER

BYPASS HUMIDIFIER

MODEL HUMBBLBP2018-A--

BYPASS HUMIDIFIER

MODEL HUMBBSBP2017-A--

installation and

start-up instructions

HUMIDIFIERS AND

HUMIDISTAT

Cancels:

II 912D-56-3

II HUM-56-1

7-98

HUM

—1—