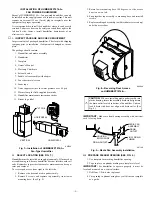

5. Attach transfer tube to solenoid valve and insert free end

into inlet fitting on top of unit housing.

6. Attach bridge rectifier to solenoid valve.

7. Insert sheet metal screws into lower holes in plenum,

pre-drilled using template.

8. Tighten screws until heads protrude approximately 3/16-in.

9. Hang humidifier on bottom screws and push top of humidi-

fier to plenum, aligning top screw holes with flange, and

insert screws.

10. Align and level unit.

11. Tighten all screws for air tight seal.

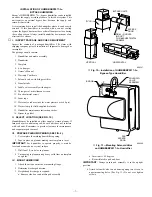

V.

INSTALL BYPASS DUCT

Attach field-supplied 6-in. diameter duct, elbow, or starting collar

with field-supplied 1/4-in. zip screws. Install supplied 6-in. damper

in 6-in. duct connector.

IMPORTANT:

On systems with central cooling, the damper

should be closed during cooling season to prevent bypass air.

CAUTION:

Do not support weight of bypass duct from

humidifier — damage could result.

VI.

INSTALL DRAIN LINE

1. Use 5/8-in. ID vinyl tubing (field supplied) to connect drain

on bottom of humidifier housing to an open drain.

2. Use worm clamp to hold drain tubing in position over drain

fitting outlet.

CAUTION:

Unit may leak if drain tubing is misapplied.

Do not insert tubing inside of drain fitting outlet.

3. Make sure line is free of traps due to sagging and has

sufficient pitch to drain.

VII.

MAKE WATER CONNECTION

If garden hose is not used for water supply:

1. Mount saddle valve on water line according to instructions

supplied with valve.

2. Run 1/4-in. diameter (water line grade) tubing from saddle

valve to adapter on solenoid valve and tighten compression

fittings.

IMPORTANT:

If water pressure is higher than normal (60 psi),

use noise suppression disk included in parts bag. (Read water noise

reducer note located inside package for instructions). For normal

operation, saddle valve need only be opened 1 full turn to meet

performance requirements.

3. Open valve and check installation for leaks.

NOTE:

Saddle valve is self piercing on copper lines; 1/4-in. hole

must be drilled in steel or iron pipes. Use only a grounded drill or

a hand drill to avoid shock hazard. Turn off water and drain the

pipe prior to drilling 1/4-in. hole.

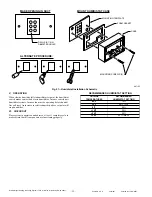

VIII.

INSTALL HUMIDISTAT AND COMPLETE WIRING

1. Mount humidistat on inside wall, or return-air duct in

accordance with section INSTALLATION OF HUMIDIS-

TAT on page 10.

2. Wire brown low-voltage leads to furnace control board, or

install

a

field-supplied

step-down

transformer

115vac/24vac 60Hz to power solenoid valve. (See Fig. 4.)

Make sure bridge rectifier is attached to coil of solenoid

valve.

NOTE:

Wiring must comply with National Electrical Code and

any local codes or ordinances that may apply.

IX.

START-UP

1. Open saddle valve to permit water flow to the solenoid.

2. Check all connections for water leaks.

3. Set thermostat to call for heat. Set humidistat for highest

humidity setting making sure contacts are closed. After a

few minutes of operation, check the drain connection for

leaks and to see if water is flowing through humidifier.

4. Reverse thermostat and humidistat settings to insure proper

shutdown.

5. Reset thermostat to normal setting. Reset humidistat to

recommended setting.

X.

FINAL STEPS

Attach humidifier maintenance instruction sticker to a visible

location.

1. Inform homeowner of proper operation, maintenance, and

humidistat setting.

a. If unit is installed during cooling season, close bypass

damper, set humidistat for summer setting (OFF or

lowest setting).

b. If installed during heating season, set unit for normal

operation.

INSTALLATION OF HUMBBWTR2019-A--

BYPASS WATER SAVER HUMIDIFIER

Bryant’s HUMBBWTR2019-A-- bypass water saver humidifier

can be installed on either the supply or return plenum of a

forced-air system. This unit requires an external bypass duct

between the supply- and return-air ductwork.

It is recommended to install the humidifier where it can be easily

serviced. If this humidifier is installed with a central cooling

system the factory-supplied 6-in. shutoff damper must be installed

to close during the cooling season to prevent bypass air. Always

install humidifier downstream of an electronic air cleaner.

I.

INSPECT PACKAGE AND CHECK EQUIPMENT

Inspect contents of packaged humidifier. File claim with shipping

company prior to installation if shipment is damaged or incom-

plete.

The package should contain:

1. Humidifier and media assembly

2. Humidistat

3. Template

4. Ten ft 1/4-in. water supply tubing

5. Owner’s Manual

6. Warranty Certificate

7. Support Bracket

8. One 1/4-in. blunt point screw

9. Saddle valve assembly

10. Four sheet metal screws

11. 6-in. damper

12. Worm clamp for field-supplied drain tube

13. Humidifier maintenance instruction sticker

14. Bryant logo label

—8—

→

→

→

→

→