8

Connect Ground and Power Wires

Connect ground wire to ground connection in control box for

safety. Connect power wiring to contactor as shown in Fig. 8.

DISCONNECT

PER N.E.C. AND/OR

LOCAL CODES

CONTACTOR

GROUND

LUG

FIELD GROUND

WIRING

FIELD POWER

WIRING

BLUE

3 PHASE ONLY

A94025

Fig. 8

---

Line Connections

A00010

Fig. 9

---

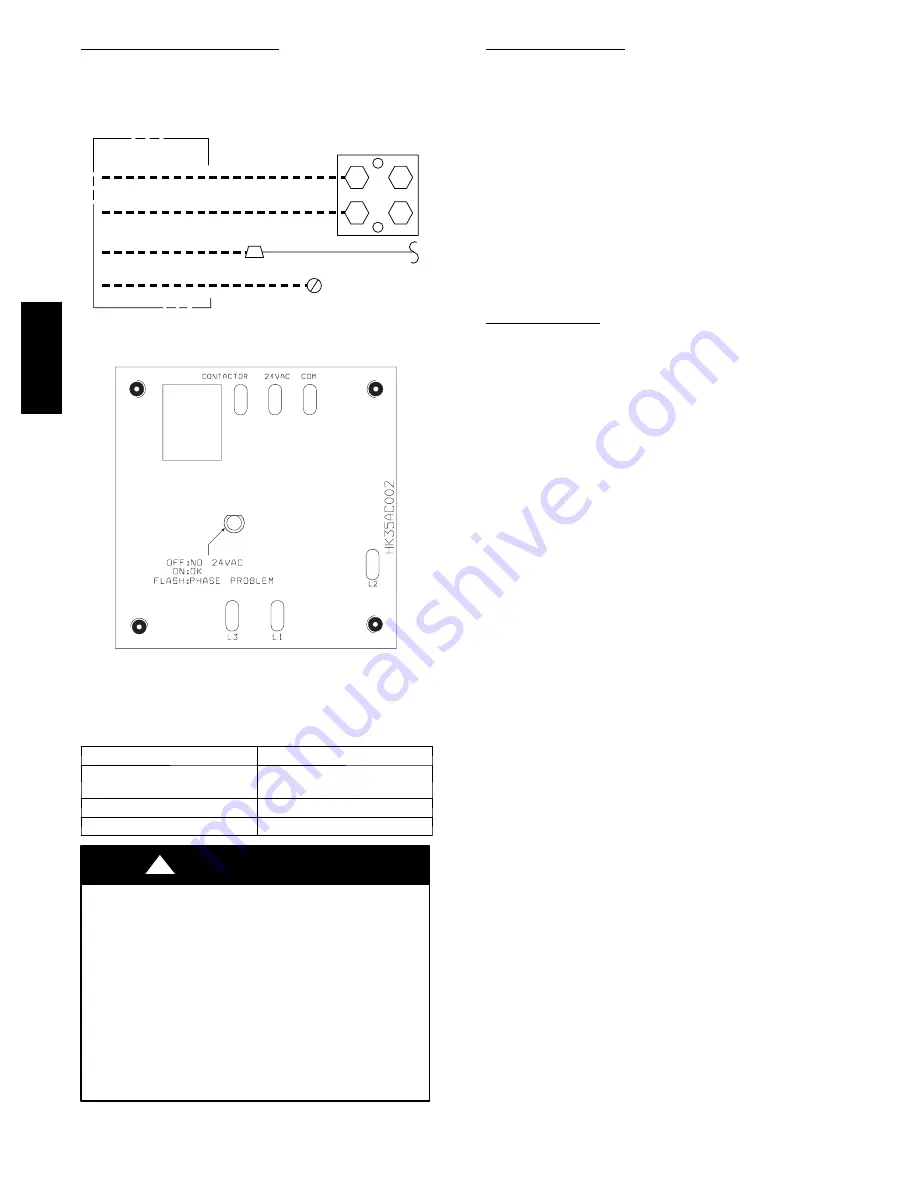

3--Phase Monitor Control

(Applies to 3--Phase Units Only)

Table 3—Phase Monitor LED Indicators

LED

STATUS

OFF

No call for compressor opera-

tion

FLASHING

Reversed phase

ON

Normal

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Ensure compressor rotation is correct.

S

3--phase scroll compressors are rotation

sensitive.

S

A flash LED on phase monitor indicates

reverse rotation. (See Fig. 9 and Table 3)

This will not allow contractor to be energized.

S

Disconnect power to unit and interchange 2

field--wiring leads on unit contactor.

CAUTION

!

Connect Control Wiring

Route 24--v control wires through control wiring grommet and

connect leads to control wiring. Refer to Installation Instruction

packaged with thermostat.

Use No. 18 AWG color--coded, insulated (35

_

C minimum) wire.

If thermostat is located more than 100 ft. from unit, as measured

along the control voltage wires, use No. 16 AWG color--coded

wire to avoid excessive voltage drop.

All wiring must be NEC Class 1 and must be separated from

incoming power leads.

Use furnace transformer, fan coil transformer, or accessory

transformer for control power, 24--v/40--va minimum.

NOTE

: Use of available 24--v accessories may exceed the

minimum 40--va power requirement. Determine total transformer

loading and increase the transformer capacity or split the load

with an accessory transformer as required.

Final Wiring Check

IMPORTANT

: Check factory wiring and field wire connections

to ensure terminations are secured properly. Check wire routing

to ensure wires are not in contact with tubing, sheet metal, etc.

STEP 8

—

Compressor Crankcase Heater

When equipped with a crankcase heater, furnish power to heater a

minimum of 24 hr before starting unit. To furnish power to heater

only, set thermostat to OFF and close electrical disconnect to

outdoor unit.

A crankcase heater is required if refrigerant tubing is longer than

80 ft. Refer to the Longline Guideline Section -- Residential

Split--System Air Conditioners and Heat Pumps Using Puron

Refrigerant.

STEP 9

—

Install Electrical Accessories

Refer to the individual instructions packaged with kits or

accessories when installing.

123A

/124A