8

gas supply piping for 0.5 IN. W.C. maximum pressure drop. Never

use pipe smaller than the 1/2--in. (12.7 mm) FPT gas inlet on the

unit gas valve.

For natural gas applications, the gas pressure at unit gas connection

must not be less than 4.0 IN. W.C. or greater than 13 IN. W.C.

while the unit is operating. For propane applications, the gas

pressure must not be less than 11.0 IN. W.C. or greater than 13 IN.

W.C. at the unit connection.

A 1/8--in. (3.2 mm) NPT plugged tapping, accessible for test gauge

connection, must be installed immediately upstream of the gas

supply connection to the gas valve.

When installing the gas supply line, observe local codes pertaining

to gas pipe installations. Refer to the NFGC NFPA 54/ANSI

Z223.1 latest edition (in Canada, CAN/CSA B149.1).

NOTE

: In the state of Massachusetts:

1. Gas supply connections MUST be performed by a licensed

plumber or gas fitter.

2. When flexible connectors are used, the maximum length

shall not exceed 36 in. (915 mm).

3. When lever handle type manual equipment shutoff valves

are used, they shall be T--handle valves.

4. The use of copper tubing for gas piping is NOT approved

by the state of Massachusetts.

In the absence of local building codes, adhere to the following

pertinent recommendations:

1. Avoid low spots in long runs of pipe. Grade all pipe 1/4 in.

(6.35 mm) for every 15 ft (4.6 m) of length to prevent traps.

Grade all horizontal runs downward to risers. Use risers to

connect to heating section and to meter.

2. Protect all segments of piping system against physical and

thermal damage. Support all piping with appropriate straps,

hangers, etc. Use a minimum of one hanger every 6 ft (1.8

m). For pipe sizes larger than 1/2 in., (12.7 mm) follow

recommendations of national codes.

3. Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections. Use

only pipe dope that is resistant to action of liquefied

petroleum gases as specified by local and/or national codes.

Never use Teflon tape.

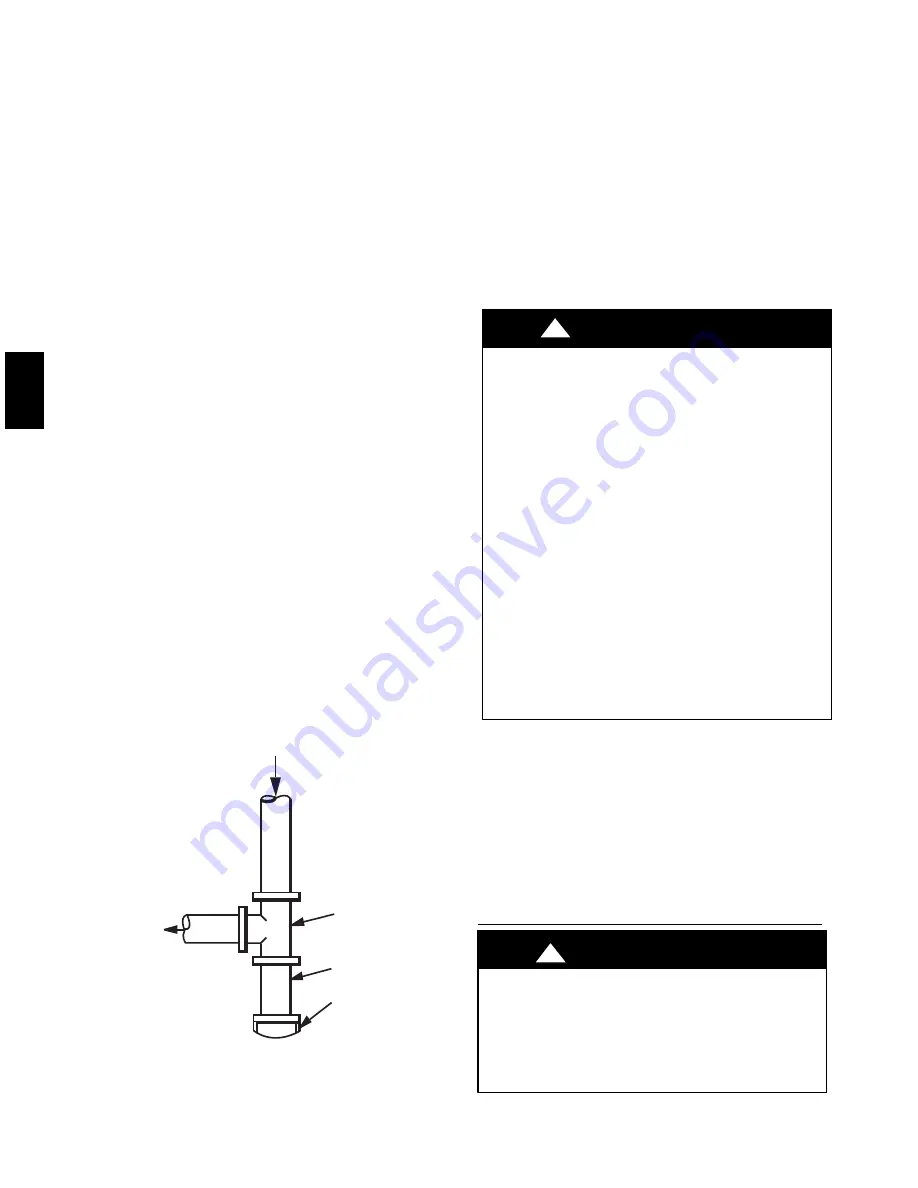

4. Install sediment trap in riser leading to heating section (See

Fig. 7). This drip leg functions as a trap for dirt and

condensate.

OUT

TEE

NIPPLE

CAP

IN

C99020

Fig. 7 -- Sediment Trap

5. Install an accessible, external, manual main shutoff valve in

gas supply pipe within 6 ft (1.8 m) of heating section.

6. Install ground--joint union close to heating section between

unit manual shutoff and external manual main shut--off

valve.

7. Pressure test all gas piping in accordance with local and

national plumbing and gas codes before connecting piping

to unit.

NOTE

: Pressure test the gas supply system after the gas supply

piping is connected to the gas valve. The supply piping must be

disconnected from the gas valve during the testing of the piping

systems when test pressure is in excess of 0.5 psig. Pressure test the

gas supply piping system at pressures equal to or less than 0.5 psig.

The unit heating section must be isolated from the gas piping

system by closing the external main manual shutoff valve and

slightly opening the ground--joint union.

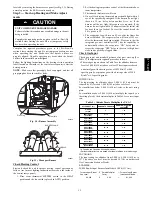

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

--Connect gas pipe to unit using a backup wrench to avoid

damaging gas controls.

--Never purge a gas line into a combustion chamber. Never

test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of

leaks to check all connections. A fire or explosion may result

causing property damage, personal injury or loss of life.

--Use proper length of pipe to avoid stress on gas control

manifold.

--If a flexible connector is required or allowed by authority

having jurisdiction, black iron pipe shall be installed at

furnace gas valve and extend a minimum of 2 in. (51 mm)

outside furnace casing.

--If codes allow a flexible connector, always use a new

connector. do not use a connector which has previously

serviced another gas appliance.

!

WARNING

8. Check for gas leaks at the field--installed and

factory--installed gas lines after all piping connections have

been completed. Use a commercially available soap solution

made specifically for the detection of leaks (or method

specified by local codes and/or regulations).

Step 9 — Install Duct Connections

The unit has duct flanges on the supply-- and return--air openings

on the side and bottom of the unit. For downshot applications, the

ductwork connects to the roof curb (See Fig. 2 and 3 for

connection sizes and locations).

Configuring Units for Downflow (Vertical) Discharge

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing system, always turn off main

power to system and install lockout tag. There may be more

than one disconnect switch.

!

WARNING

677C

--

--

C

Summary of Contents for Legacy 677C**C Series

Page 3: ...3 A150538 Fig 2 24 30 Unit Dimensions 677C C...

Page 4: ...4 A150539 Fig 3 36 60 Unit Dimensions 677C C...

Page 44: ...44 A150506 Fig 15 208 230 1 60 Connection Wiring Diagram 677C C...

Page 45: ...45 A150516 Fig 15 Cont 208 230 1 60 Ladder Wiring Diagram 677C C...

Page 46: ...46 A150507 Fig 16 208 230 3 60 Connection Wiring Diagram 677C C...

Page 47: ...47 A150517 Fig 16 Cont 208 230 3 60 Ladder Wiring Diagram 677C C...