Motor-driven blocking device EasyBlocker

Installation

instruction

108320

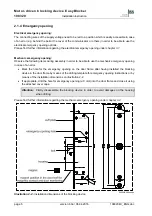

2.1.2 Counterpart

The counterpart is assembled in the door leaf. It needs to be assembled in a way that the bolt can extend

to the limit stop without contact. The maximum distance between the cuff plate and the counterpart

amounts to 8 mm. This way, it is guaranteed that the bolt will move far enough into the counterpart.

Assembly steps:

1.

After having installed the blocking device, connect it to the test device (

refer to the

instructions of

the test equipment for the connecting diagram

). After supplying the distribution voltage (e.g. using

an accumulator) the blocking device will open automatically.

2.

Glue the assembly aid (adhesive felt) on the bolt of the blocking device and color it using an ink

pad.

3.

Close the door.

4.

Lock the blocking device using the test device. The bolt will extend. After several locking trials the

bolt will move back since it cannot reach the end position.

5.

Open the door.

6.

On the door leaf you will recognize a color circle which shows the exact position of the counterpart.

7.

Mark the center using a center punch and drill the hole according to the dimensions of the

counterpart. Please find the installation dimensions of the counterpart on the technical data sheet

(also refer to

8.

Assemble the counterpart.

9.

Close the door and perform a functional check using the test device (also refer to

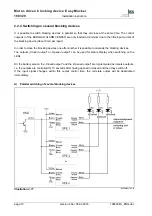

2.1.3 Magnetic contact

When using the magnetic contact install the magnet (8 mm x 30 mm) which is included in the delivery into

the door leaf beside the counterpart. To do so, place a hole of ø 8 mm and a depth of 30 into the door

leaf.

You will find the correct position of the magnet in

illustration 2-2

or determine the position by means of the

attached drilling template for the magnetic contact.

Attention:

On metal doors the magnetic force to switch the reed contacts is significantly reduced.

Please check on site if it is necessary to use magnets of higher retention force.

It is possible to order a special magnet for metal doors under item No. 108320.M.

108320Err_ENG.doc

version 6.0a / 06.04.2016

page 5