22

EN

MANUALE_SP3600_BWT-A5 - Rev: 01/2020

parts and relevant documentation”.

For regular control:

• Check that the mechanical parts are tightly se-

cured and check the condition of the screws sup

porting the product.

• Check that the power cord and isolating parts are

in their correct position, are secure and in a good

state of repair.

• Check the temperature of the product and the

electric motor. In the event of a fault, stop the

product immediately and contact specialised

technicians.

• Check for product vibrations. In the event of a

fault, stop the machine immediately and contact

specialised technicians.

7.1. Routine maintenance.

To be performed at least once a year, or more fre-

quently if necessary.

Product components that, due to their normal use,

suffer wear and/or tear must be regularly replaced to

ensure good product performance. The following ta-

ble shows the perishables and/or consumables used

in the product and their estimated working life.

O rings and

general seals

1 year

Mechanical seal

TAB. 6

7.2. Extraordinary maintenance.

Extraordinary product maintenance must be per

formed by a specialised technicians.

This consists in replacing worn or damaged parts

(power cord,

bearing

,

rotor

,

impeller

, etc.).

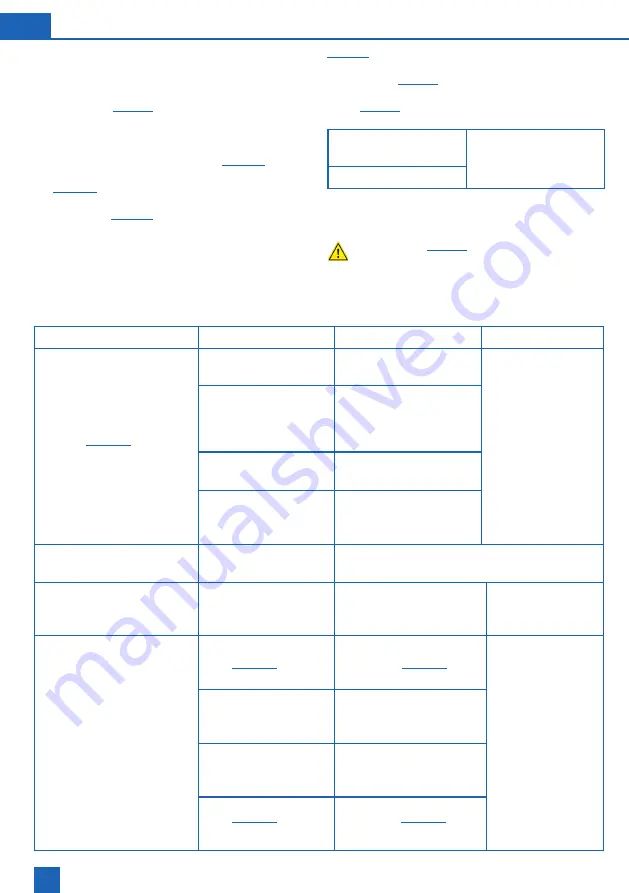

8. Troubleshooting.

PROBLEMA

POSSIBILE CAUSA

1° SOLUTION

2° SOLUTION

1. The product

does not work.

No or insufficient

power supply.

Check the power

supply.

Contact special-

ised technicians.

The

power plug

is not correctly in-

serted in the

power

outlet

.

Firmly insert the

pow

-

er plug

in the

power

outlet

.

The vent is clogged

by dirt, Fig. 17.

Clean the vent.

Hydraulic compo-

nents clogged or

bent.

Clean and adjust

hydraulic components.

2. Power cord damaged. Wear and/or negli-

gence.

Contact specialised technicians.

3. Plastic components

damaged.

Wear.

Replace.

Contact special-

ised technicians.

4. Low

flowrate

from

outlet

.

The product is dirty

Clean the product.

Contact special-

ised technicians.

Hydraulic compo-

nents clogged or

bent.

Clean and adjust hy-

draulic components.

The

impeller’s

blades are worn out. Replace the

impeller

.

The product is not

trimmer correctly.

Trime the product like

illustrated in Fig. 16.