Maintenance

General

© BT

Repair manual

SWE100, 120, 120L, 120S, 140, 140L, 200D

5 – 1

Order no..

Date

Valid from serial no.

T code

258946-120

2012-08-30

6061850-

841×842×843

5 – Maintenance

5.1 General

This chapter contains a general periodic maintenance schedule and a

more detailed description of the maintenance to be carried out.

5.2 Service intervals

The service intervals are for guidance only and do not need to be

strictly followed. The service technician should adapt these to local

requirements, however, it is important that the intervals coincide with

the minimum requirements of the truck manufacturer.

The service intervals are based on operating hours and can be adapted

to most standard 8-hour shifts. The following operating hours have

been used when calculating the intervals:

Daytime: 08.00-17.00 (20 h/week)

2 shifts: 06.00-14.00, 14.00-22.00 (40 h/week)

3 shifts: 06.00-14.00, 14.00-22.00, 22.00-06.00 (60 h/week)

Make sure the truck undergoes regular maintenance at intervals of 750

operating hours. The safety, efficiency and expected service life of the

truck depend on the service and maintenance the truck receives.

Following completed service intervention, test drive the truck and

perform an operational inspection. See the Installation chapter under

the heading Function and safety checks.

For service and repairs, only use spare parts approved by truck

manufacturer.

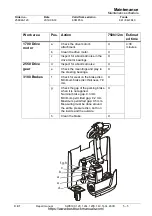

5.3 Maintenance schedule

Service maintenance should be performed in intervals of 750 operating

hours or every 12 months, whichever occurs first.

The order in the maintenance schedule is not optimal for the working

order; it is simply sorted according to the C codes.

https://www.besttruckmanuals.com/