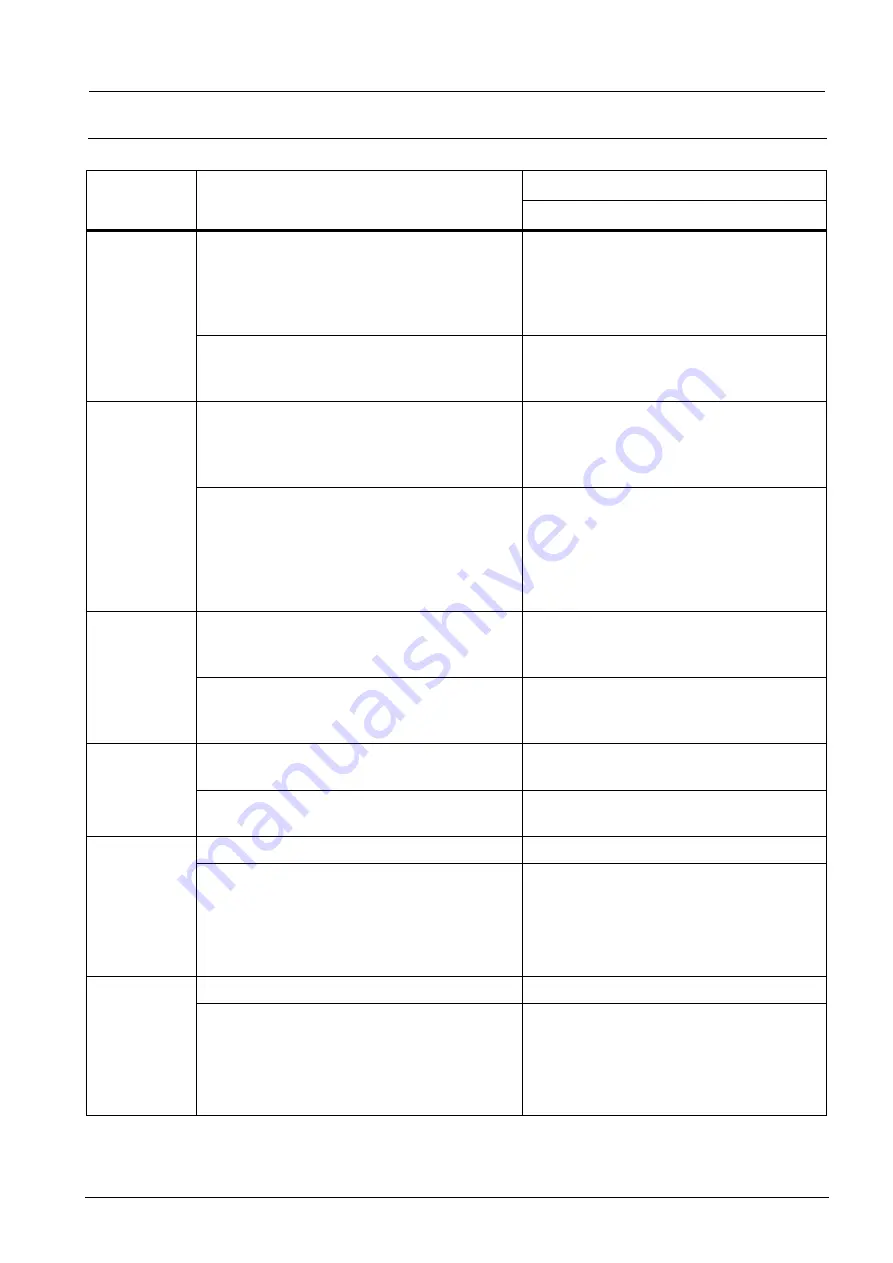

Troubleshooting

Error codes

© BT

Repair manual

SWE100, 120, 120L, 120S, 140, 140L, 200D

7 – 7

Order no..

Date

Valid from serial no.

T code

258946-120

2012-08-30

6061850-

841×842×843

2.004

No event. Truck can be operated as usual.

Values stored in the transistor regulator

back-up copy differ from the values

stored in the logic card of the handle in

terms of parameters, hour counter and/

or machine serial number.

Use TruckCom to check where the

correct data are stored. See table

7.6.4.

2.101

Safety speed, raising and lowering the

forks not working.

The truck type has not been set.

Alternatively, the value in the tiller arm

logic card [A5] is different from the

value in the transistor regulator [T1].

Reset data from backup, See section

"15.5.4 Disassembly/assembly of tiller

arm handle". If this does not help,

indicate the type of truck by entering

factory parameter 1001 (Truck type), or

see table 7.6.4.

2.102

Safety speed, raising and lowering the

forks not working.

The set truck type does not support

analogue lifting and lowering

operations.

Check the settings of factory

parameters 1001 (Truck type) and

1023 (Controls for hydraulic functions).

2.501

Main contactor opens.

Low battery voltage <16.8V> for more

than 2 seconds

Charge the battery. Inspect all cables

and connectors

2.511

The main contactor is open.

CAN communication error.

Check:

•

connections and wiring harness

•

cables 119 and 120

•

logic card in tiller arm handle.

2.514

The main contactor is open.

CAN communication error.

Check:

•

connections and wiring harness

•

cables 119 and 120.

•

logic card in tiller arm handle.

Code

Event

Possible cause

Action

https://www.besttruckmanuals.com/