At this point, the primary structures of the wing panels are complete. The last major part, the top center

sheeting, will be added after the wing panels are joined (this allows easy access to the dihedral braces so

you can be certain they are glued properly). This section wraps up some of the detail work on the wing

panels that is easier to do before the panels are joined.

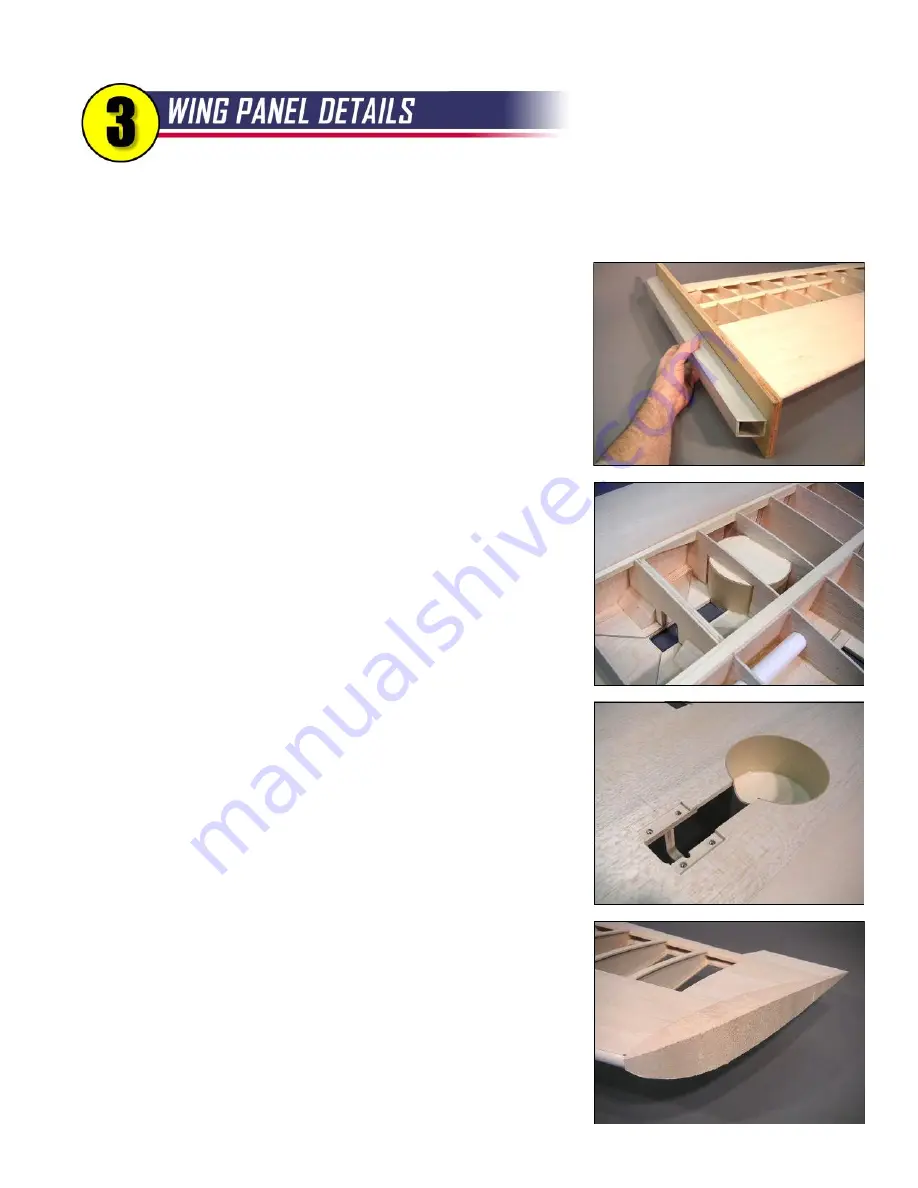

Trim the wing sheeting and spars at each end of the wing panel,

flush with ribs W-1 and W-14. It's critical to sand the root end accurately

so the panels will make firm contact with each other when joined. I made

myself an oversized sanding block just for this purpose using scrap

plywood, an aluminum bar, and a cut up sanding belt.

Trim the TE sheeting flush with the trailing edge. Maintain the

bevel in the inboard section of the wing panel.

Now you can finally cut the wheel opening and the wheel wells

away from W-4 and W-5 along the vertical lines you drew earlier.

Dry assemble the 1/32" plywood wheel well liner and the lite-ply

wheel well floor in the wing. The liner can be overlapped in the area cutout

for the strut, or you can trim the liner for a butt joint - your choice. When

satisfied with the fit and position of the parts, glue everything in place with

medium CA.

Use a sanding drum in a Dremel tool to make a rounded notch in

the liner to clear the wheel strut. Make a smaller notch in the retract mount

to clear the brass nipple on the side of the Robart retract unit.

Accurately place your retract unit in the wing and mark the position

of the mounting holes on the plywood mount. Remove the unit, then drill

the holes carefully for blind nuts. Install the retract mounting blind nuts and

fix them in place with medium CA.

Note 1:

Hardware for retract mounting

is not provided in the R54 kit, but it IS provided in the optional Retract

Package available from BTE.

Note 2:

If you do not have your retract units

at this time, you can still do this step using the Robart Bolt Pattern

Template provided in the kit.

Glue the wingtip trailing edge extension to the wing, using the

plans as a guide for proper placement. When dry, trim the end to match

the angle of rib W-14.

The balsa wingtip block is roughly cut to match the wing top view.

Mark the airfoil shape on the block using the actual wing as a pattern, then

saw the block to a rough airfoil shape. Glue the wingtip block in place with

yellow glue using pins and tape to hold it in position until dry.

11

Summary of Contents for Reaction 54

Page 1: ...INSTRUCTION BOOK...