Glue two pieces of 3/32" balsa sheet, 1-1/2" wide, to the bottom

of the fuselage as shown in the photo. These are the areas where the

two fin posts make contact. For now, it helps to leave the rest of the

fuselage bottom opened for access while installing the pushrods and

fin post braces. Sand all of the balsa sheeting flush with the fuselage

sides.

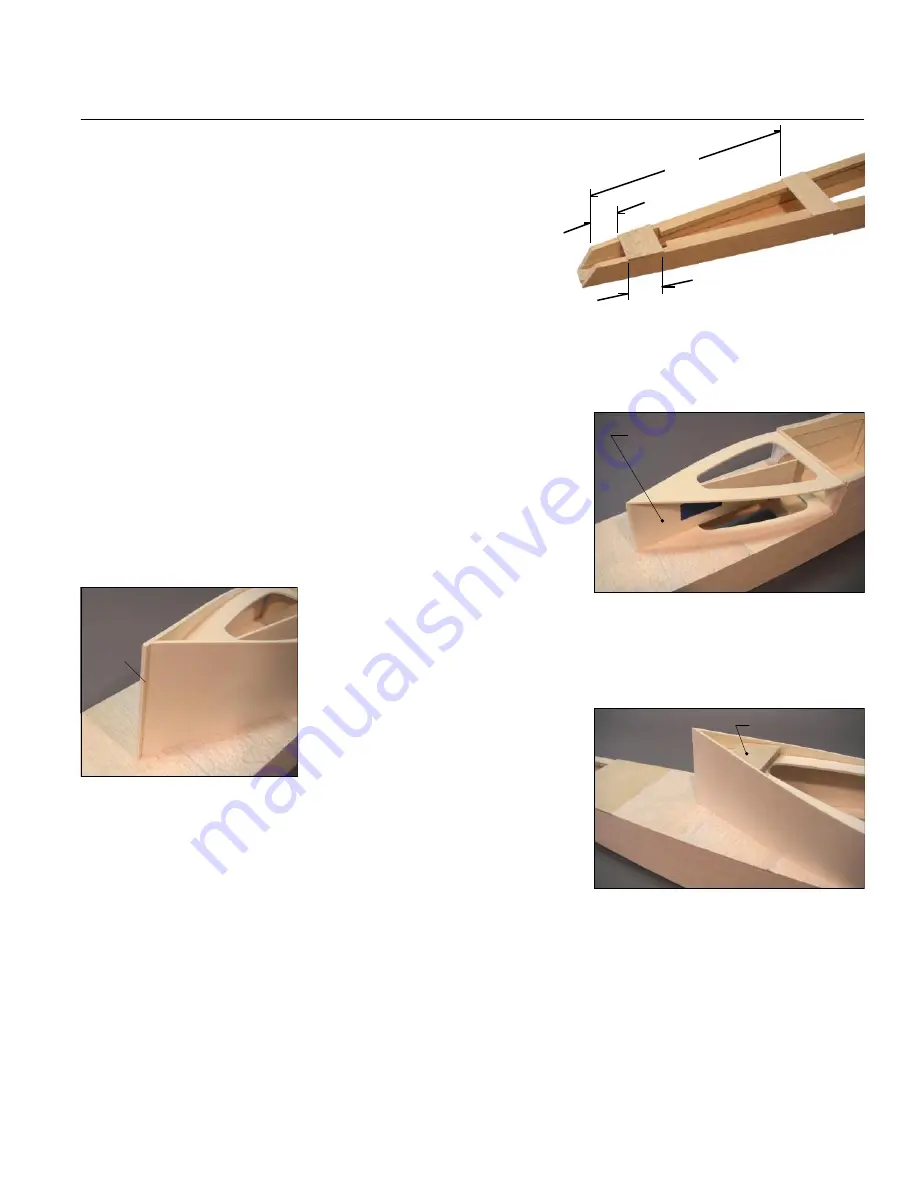

Glue one of the boat tail formers to the sheeting, making sure the

point is centered side-to-side. Cut away the balsa sheeting to match the hole in the boat tail former.

Add the boat tail jig. Glue the aft end of the jig firmly, but just spot glue the front end on F-6. Make sure the jig is

centered and vertical. The jig is symmetrical, so it can be installed with either side pointing up.

Glue the second boat tail former in place. The front edge should be

parallel to the bottom edge of F-6.

Carefully sand the back edge of the boat tail jig to match the contour of

the formers and provide a wider gluing surface for the sides which are to be

added next. You can protect the balsa sheeting by putting masking tape on

the edge of your sanding block for this operation.

Now glue either one of the boat tail

sides in place. The front edge of the boat tail side sits in the notch in SIDE-1. The

rear edge of the boat tail side will have to be trimmed to match the angle of the

formers and jig. Glue on the second boat tail side, then trim its rear edge to form a

sharp point. The whole idea of the boat tail section is provide a smooth flow of air

to the turbine intake.

Remove the tape on the boat tail jig

and break out the front portion.

Firmly glue the 3/8" plywood wing mount in the rear of the boat tail.

Use a sanding block to smooth the top edges of the fuselage in

preparation for the balsa sheeting.

Sheet the top of the hatch with 1/4" balsa sheet applied cross-grain. The sheeting must end right at the front and

rear corners of the hatch sides. Use yellow glue for this step because this glue joint will have to be sanded later. Hold

the sheeting in place with long strips of masking tape.

Glue 1/4" balsa sheeting to the top of the fuselage at the nose being careful to not glue it to the hatch sheeting.

When dry, remove all the tape from the sheeting and from the bulkheads inside the fuselage. You should now be

able to separate the nearly-complete hatch from the fuselage. Grab your bottle of medium CA and go over both sides

of every joint in the fuselage and hatch.

R54

FUSELAGE CONSTRUCTION

,

continued...

20

10"

1¼"

1½"

- 2 places

Trim

Wing Mount

Boat Tail Jig

Summary of Contents for Reaction 54

Page 1: ...INSTRUCTION BOOK...