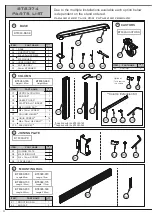

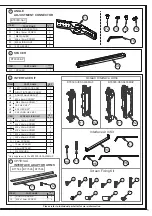

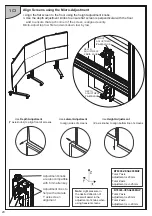

5

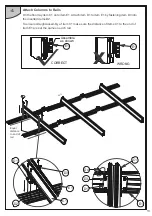

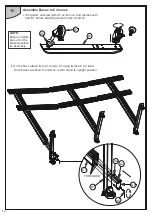

Assemble Bases to Columns

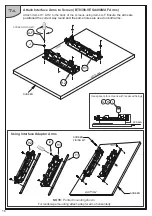

14

THREADED

A4

A3

A2

A6

A1

C1

i. If required, unscrew item A5 on item A1 and replace with

item B1 before attaching bases to the columns.

B1

A1

A5

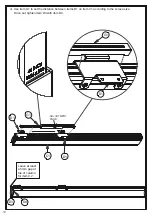

NOTE:

Ensure castors

are set on the

braked position

for assembly.

ii. On the floor, attach item A1 to item C1 using items A2, A3 & A4.

Once bases are fixed to columns, return stand to upright position.