1.3 - Measuring principle

6

TCT-2301 Product introduction

M2007/3en

©BTG 2004

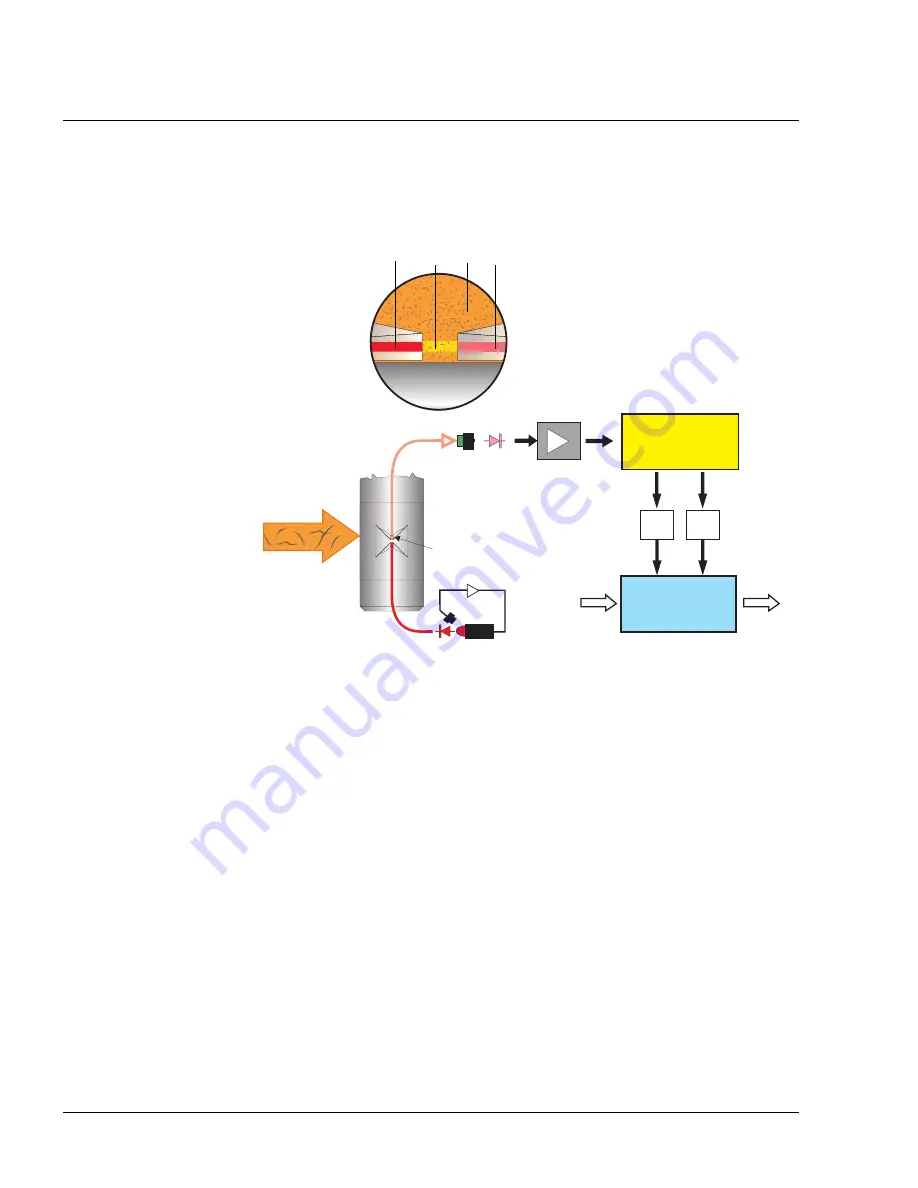

1.3 Measuring principle

1.3.1

The Peak Method

The TCT-2301 employs the patented peak method for measuring total

consistency of pulp suspensions. This technology is based on the fact that

suspensions contain both large and small particles. Large particles are

typically fibers and small particles are fillers and fines.

Close study of a suspension sample shows that the high number of small

particles in the suspension remains relatively constant over time. On the

other hand, there are far fewer large particles and their number varies sig-

nificantly over time.

The large particles form a relatively transparent network, within which

the small particles move freely. A narrow light beam directed through the

suspension is generally affected by both the large and small particles.

There is however an interval when only small particles affect the light

beam, and this is know as the "Peak" period.

During the other time periods, the light beam is affected by both the large

and small particles. Fig 2 and fig 3 illustrate this principle.

In fig 2, a light beam passes through the pulp flow (1). The transmitted

light is detected by a photo detector. The detector signal is amplified (5)

and then treated by the signal processor (6).

8

1

9

2

5

4

3

DC

PEAK

6

7

Fig 2 Operating principle

1 Pulp flow

2 Measuring gap with light beam

3 Optical fiber from light source

4 Optical fiber to detector

5 Amplifier

6 Digital signal processor

7 Microprocessor

8 Input signals

9 Output signals

2

1

4

3