Appendix A – Quick Reference

-

Symbols Key

SMART 200 MTC

- A.1 -

QUICK REFERENCE

QUICK REFERENCE

QUICK REFERENCE

QUICK REFERENCE

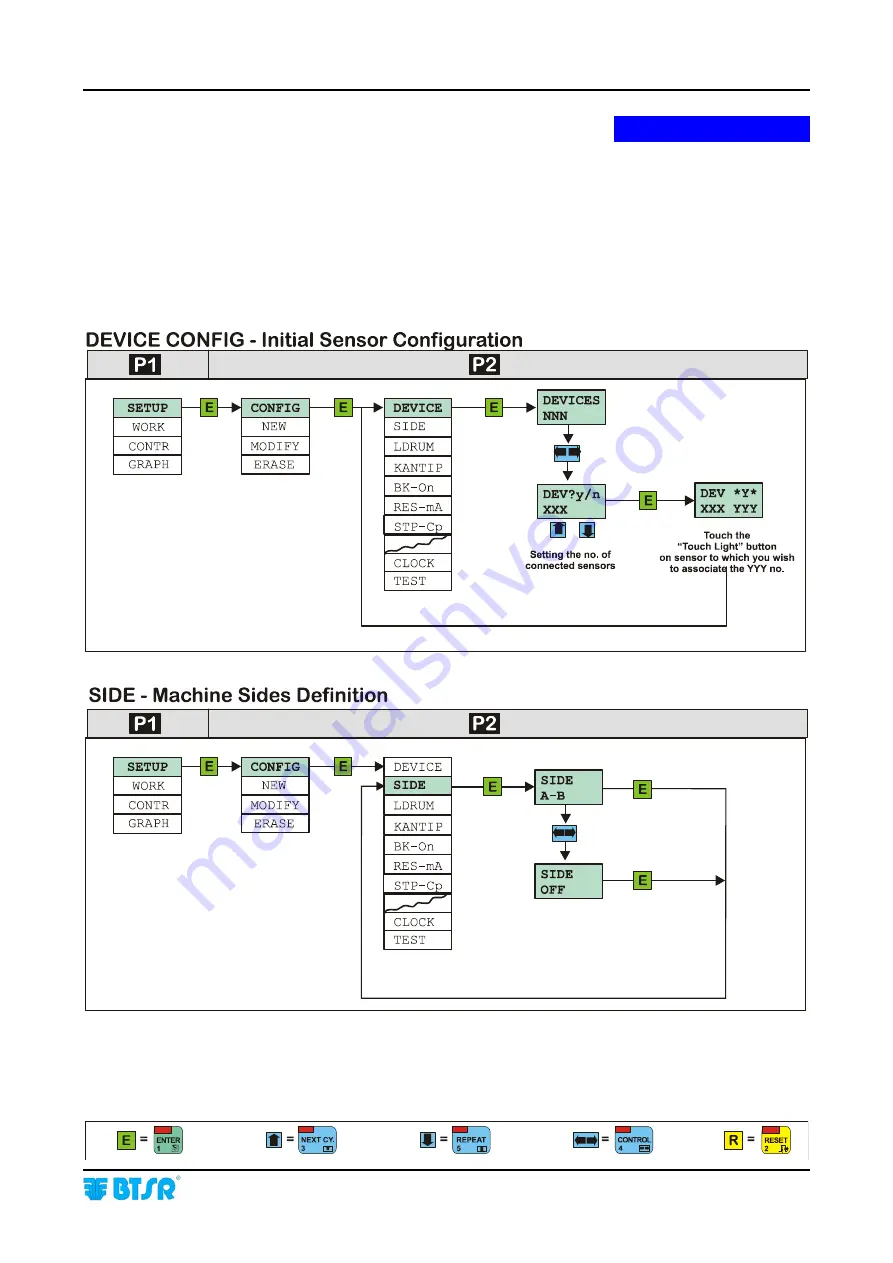

The following flow-charts shows briefly the operating sequences which are

required to complete all the functions available on the

SMART 200 MTC

system.

The use of the quick reference guide supposes that the user has already acquired a

certain ability in handling the system, therefore there are no detailed explanations

of each screen shot; there is only a global overview of sequences of the required

steps, for each function. For an explanation of the symbols used in the quick

reference guide, please refer to “Symbols key” shown at the bottom of each page.

Summary of Contents for IS3W/MTC

Page 1: ...SMART 200 MTC IS3W MTC METER CONTROL SYSTEM Operating Manual Rev 2 0 September 2003 ENGLISH ...

Page 14: ...Technical Data and Installation 2 6 SMART 200 MTC Page intentionally left blank ...

Page 26: ...Operation 3 12 SMART 200 MTC Enabling the SETUP Menu Functions ...

Page 28: ...Operation 3 14 SMART 200 MTC Enabling the GRAPH Menu Functions ...

Page 69: ...Operation SMART 200 MTC 3 55 Production Report Example ...

Page 70: ...Operation 3 56 SMART 200 MTC Page intentionally left blank ...

Page 78: ...Appendix A Quick Reference Symbols Key A 2 SMART 200 MTC ...

Page 79: ...Appendix A Quick Reference Symbols Key SMART 200 MTC A 3 ...

Page 80: ...Appendix A Quick Reference Symbols Key A 4 SMART 200 MTC NO NC ...

Page 81: ...Appendix A Quick Reference Symbols Key SMART 200 MTC A 5 ...

Page 82: ...Appendix A Quick Reference Symbols Key A 6 SMART 200 MTC ...

Page 83: ...Appendix A Quick Reference Symbols Key SMART 200 MTC A 7 ...

Page 84: ...Appendix A Quick Reference Symbols Key A 8 SMART 200 MTC ...

Page 85: ...Appendix A Quick Reference Symbols Key SMART 200 MTC A 9 ...

Page 86: ...Appendix A Quick Reference Symbols Key A 10 SMART 200 MTC ...

Page 87: ...Appendix A Quick Reference SMART 200 MTC A 11 Notes ...

Page 88: ...Appendix A Quick Reference A 12 SMART 200 MTC Page intentionally left blank ...