Overview

ULTRAFEEDER

- 1.3 -

Advantages obtained by using the ULTRAFEEDER devices

Constant yarn tension both when the machine speed changes and when the yarn

packages gradually get empty.

Best efficiency by eliminating the yarn breakage

(tears and extratensions),

and

possibility to work at the highest speed offered by the machine.

Possibility to work with a wide range of yarn types including:

-

Very thin yarns, such as bare elastomers 11/17 DTEX.

-

Very difficult yarns, such as covered elastomers

-

Elasticized yarns either bare or covered

-

Nylon, cotton, etc.

Yarn tension graduation capability, with 0.1 g. resolution

(INC/DEC function

-

BTSR

Patent).

Finished product quality optimization thanks to the Master/Slave operating mode

(

BTSR patent

)

Accurate yarn feeding speed measurement

(1 to 1500 m/min) – (LFA m/min = Length

of Absorbed Yarn).

Optimization of yarn consumption and less difficulties to keep the correct size of

manufactured products.

Drastic reduction of yarn consumption

(8% to 15% for bare elastomers, 2% - 5% for

covered elastomers).

Better quality of manufactured product

(defect free)

and drastic drop of second choice

production.

Constant keeping of set size, independently of the yarn package emptying condition.

Possibility to use the yarn up to the complete package emptying.

Better machine efficiency.

Possibility to feed the strap elastic or wrist band, guaranteeing a constant compression

(hosiery machines).

Possibility to perform gradual compression with no limits, and with a minimum

resolution of 0.1 grams.

Efficiency optimization on machines that use the yarn in non-continuous mode (Start-

Stop), thanks to the possibility to draw back immediately the yarn fed in excess

(“reverse" applications)

.

Full control of yarn presence, even during the “LEARN” phase performed with the

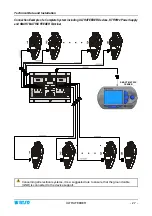

SMART MATRIX FEEDER/PFU control terminal

(“reverse" applications)

.

Possibility to find the best application conditions of ULTRAFEEDER device:

(No of

coils to be wound around the roller, ideal programming values for parameters etc),

thanks to the continuous visualization, in graphic form, of both average and peak

values of yarn tension.

Summary of Contents for ULTRAFEEDER

Page 1: ...ULTRAFEEDER YARN CONTROL SYSTEM Operating Manual ENGLISH Rev 4 1 February 2017 ...

Page 40: ...Technical Data and Installation 2 28 ULTRAFEEDER Page intentionally left blank ...

Page 72: ...ULTRAFEEDER Troubleshooting and Maintenance 4 6 ULTRAFEEDER Page intentionally left blank ...

Page 78: ...YTT Device 5 6 ULTRAFEEDER Page intentionally left blank ...